- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Tear Strength Tester Textile Lab Equipment Pendulum Type Elmendorf Tearing Test Machine M006C

Overview

The instrument adopts LCD display, the instrument automatically detects and analyzes data.This instrument has the characteristics of high test accuracy, reliable performance and simple operation.

The performance indexes of the instrument are in accordance with the relevant requirements of GB/t3917.1-2009. Suitable for the determination of tear resistance strength of various woven fabrics.It can also be used for the determination of tear resistance strength of thick paper, plastic sheet, electrical tape, etc.

Application

Standards

Textiles: GB/T 3917.1; ASTM D1424, DIN 53862; EN ISO 13937-1; ISO 4674-2; ISO 9290; M&S P29; NEXT 17; NF G07-149

Paper: GB/T455, ASTM D689, BS 4468, DIN 53128, CSA D9, ISO 1974,EN 21974, PAPTAC D9, JIS P8116, SCAN P11,UNI 6444, APPITA P400, TAPPI T414

Plastic: GB/T 11999, ISO6383-2, ASTM D1922, NF T54 141, JIS K7128-2

Non woven: ASTM D5734, WSP 100.1

Key Parameters

|

Model |

M006C |

|

Tearing force testing range |

0 ~ 16N (A hammer), 0 ~ 32N (B hammer), 0 ~ 64N (C hammer) |

|

Test accuracy |

≤ ±1%F·S |

|

Tearing length |

43mm |

|

Incision length |

20±0.2mm |

|

Power supply |

AC 220V 50/60HZ 20W |

|

Dimensions |

520×300×580mm(L x W x H) |

|

Weight |

32kg |

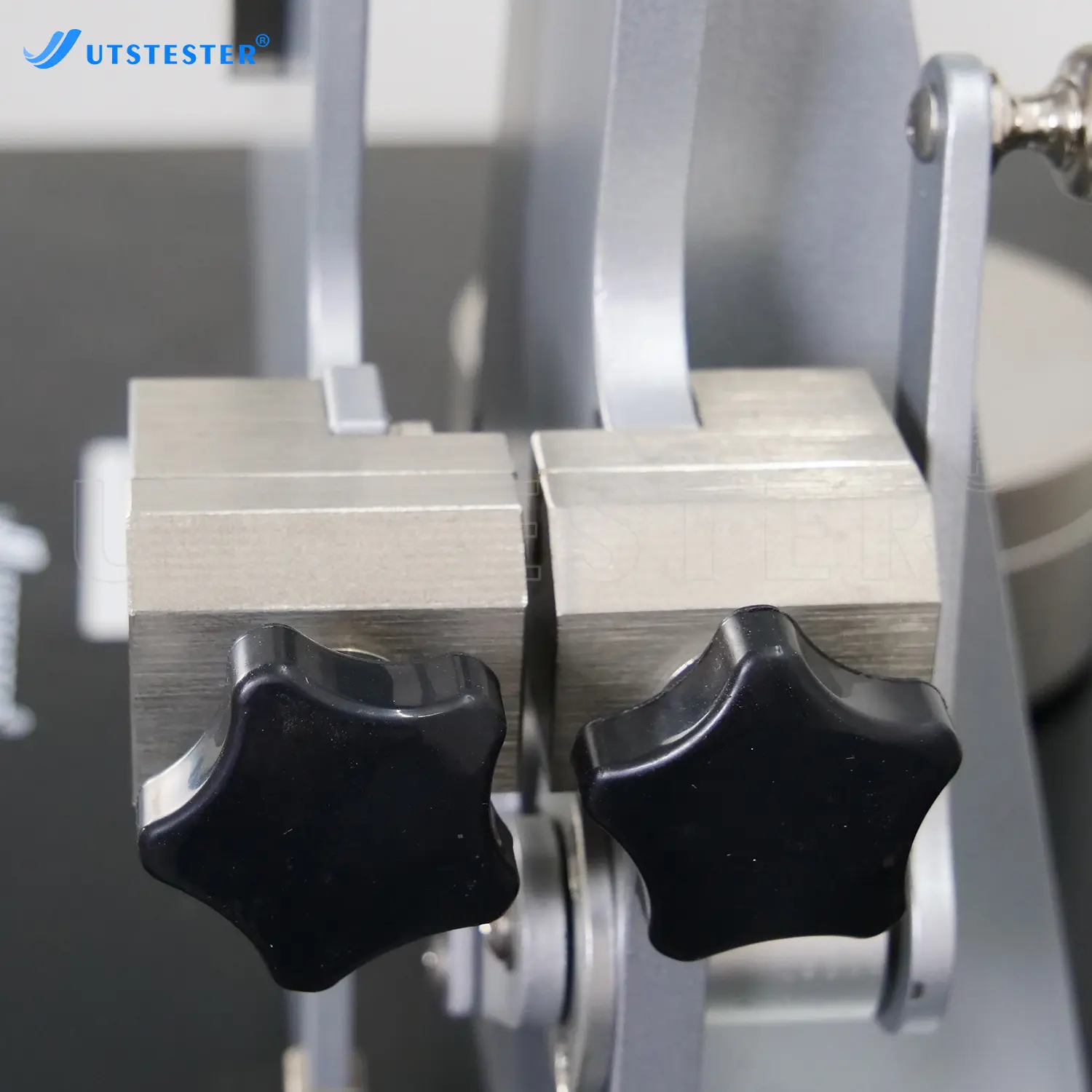

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home