- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

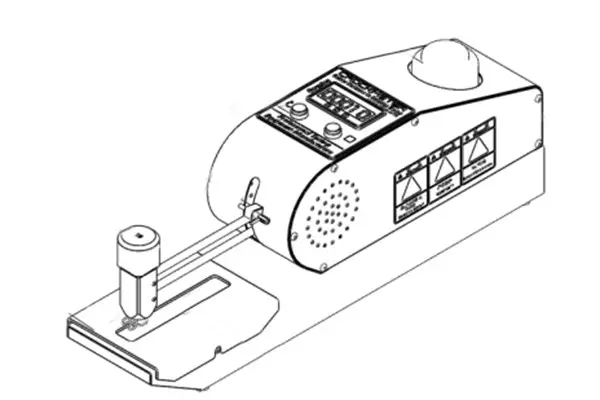

Light Fastness Tester (Air-Cooled, High Temperature) D002B

Overview

To do color fastness to light and weather test in the color fastness test. Also available for coatings, paper, paint, paint, rubber, plastic, wood, etc.

Application

Standards

GB/T8427, GB/T14576 GB/T15102-2006 GB/T15104-2006 GB/T8430

AATCC TM16 ISO105-B04 ISO105-B02

Key Parameters

| Model |

D002B |

| Test chamber temperature range |

25~50℃, resolution: 0.1℃ |

| Test chamber humidity range |

Light cycle: 10-70%RH, humidity fluctuation: ±3%RH; Dark cycle: 30-95%RH, humidity fluctuation:±5%RH; |

| Test time control |

0min~999:59h, accuracy: ±1min |

| Irradiance control |

1-1.5W/m2/420nm, accuracy: ±0.03W/m2/420nm; Digit setting, auto compensation |

| Wave length(Can be control and monitored) |

340nm, 420nm, 300-400nm, 300-800nm waveband optional |

| Xenon arc lamp rated power |

3300W |

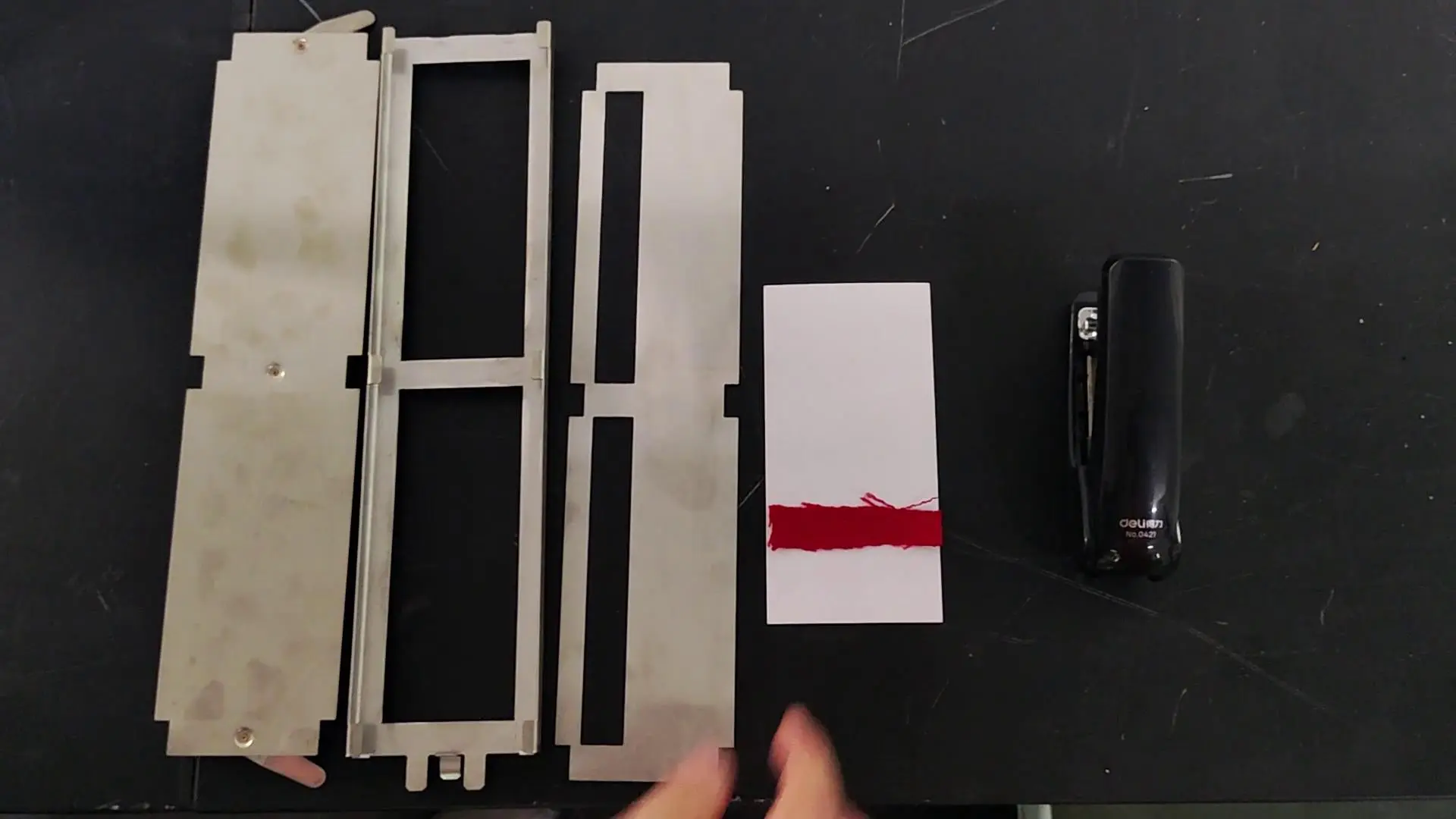

| Sample holder rotation speed |

5rpm |

| Maximum exposure area |

1755cm2 |

| Sample holder quantity |

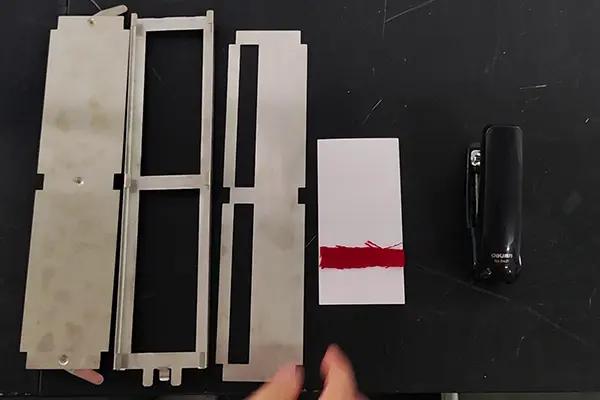

AATCC: 100x75mm 9×2 pcs or ISO: 135x45mm 12×2 pcs |

| Each sample holder timing separately |

≤10000h |

| Photoperiod |

≤10000h |

| Spray period |

≤10000h |

| Temperature range |

(BPT) 40-80℃, accurate ±2℃; (BST) 40-85℃, accurate ±2℃ |

| Display |

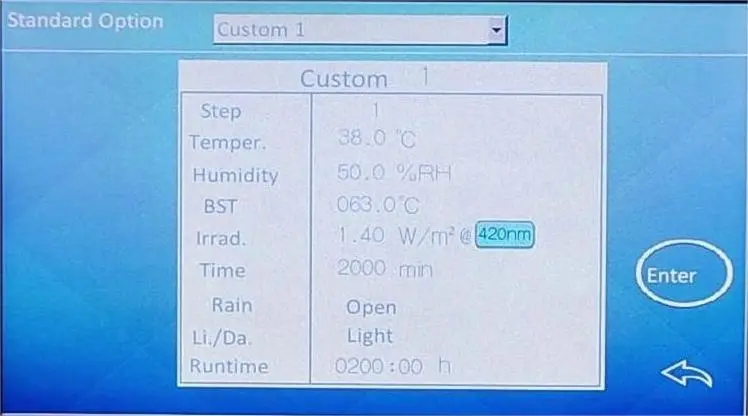

10.4inch touch screen |

| Test data print out |

Digital color screen display |

| Internal recycle water |

High pure maximum flow: 0.5L/min |

| Power |

AC380V±5% 50Hz 3.3kW |

| Dimension |

920×650×1680mm |

| Weight |

180kg |

Product Details

Production Processes

Scenarios of Use

Operation

Turn on the power switch

First close the air switch and close the red knob power switch, confirm that the touch screen control panel starts to run.

Setting parameters

Select the required standard in the setting interface as needed, set the running time, and click confirm to enter the experiment interface.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home