- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

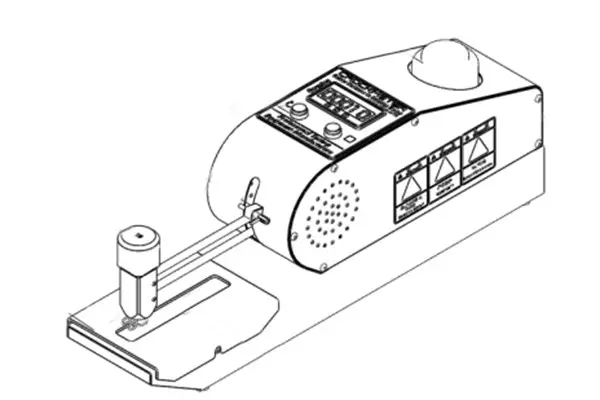

Digital Elmendorf Tearing Tester for Paper and Plastic Cloth

Overview

Application

Standards

Key Parameters

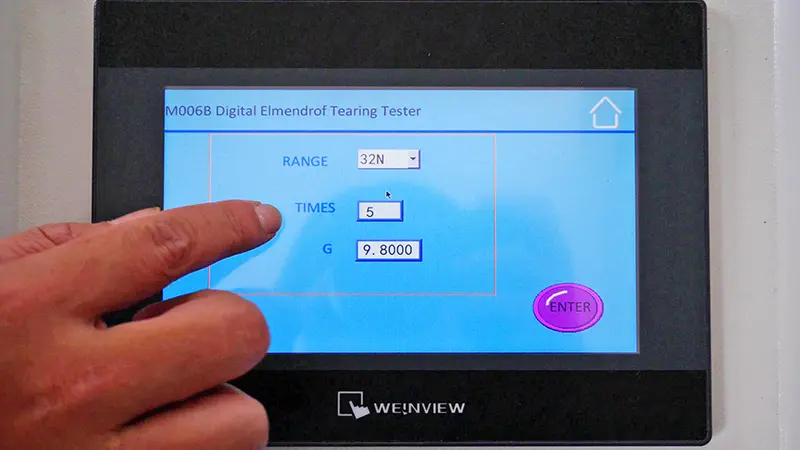

|

Model |

M006B |

|

Measuring range |

8N, 16N, 32N, 64N, 128N(5 grade measuring range) |

|

Measuring force accuracy |

±0.2%F.S |

|

Units |

mN, cN, N, g, Kg, oz, LB |

|

Maximum sample thickness |

5mm |

|

Length of incision |

20±0.2mm |

|

Tearing stroke |

86mm( Sample tearing length 43mm) |

|

Sample size |

100 x 63 mm |

|

Clamps interval |

2.8±0.2mm |

|

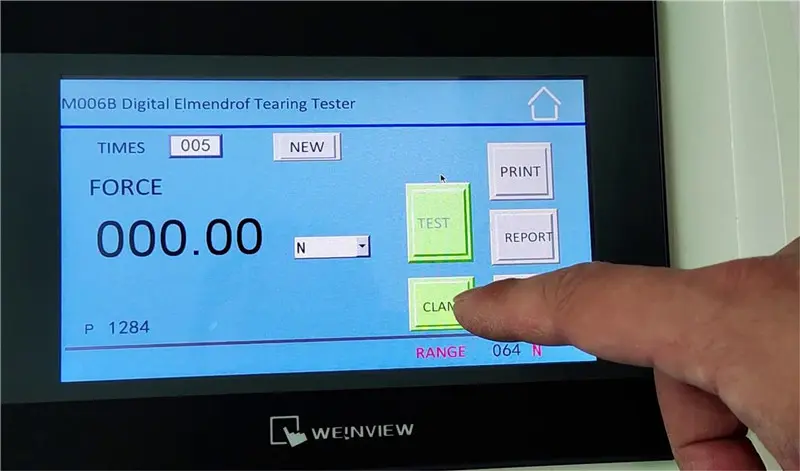

Sample clamping methods |

Pneumatic clamp |

|

Operation |

Automatic electronically controlled device with versatile tear testing options |

|

Braking system |

Electronic braking(electromagnetic) and two button release |

|

Control |

Controlled and measurements with a microprocessor |

|

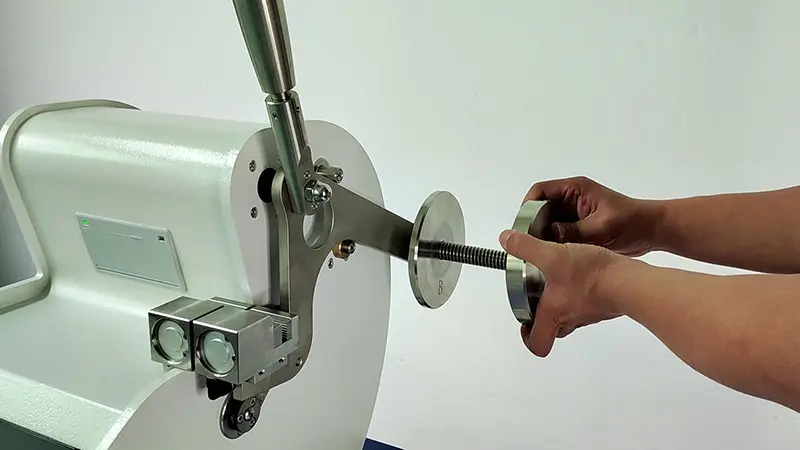

Weights |

Pendulum and verification weights of 8N, 16N, 32N, 64N, 128N(5 grade measuring range) |

|

Encoder |

Angular encoder |

|

Pendulum |

Adjustable pendulum balance |

|

Platform |

Stable platform |

|

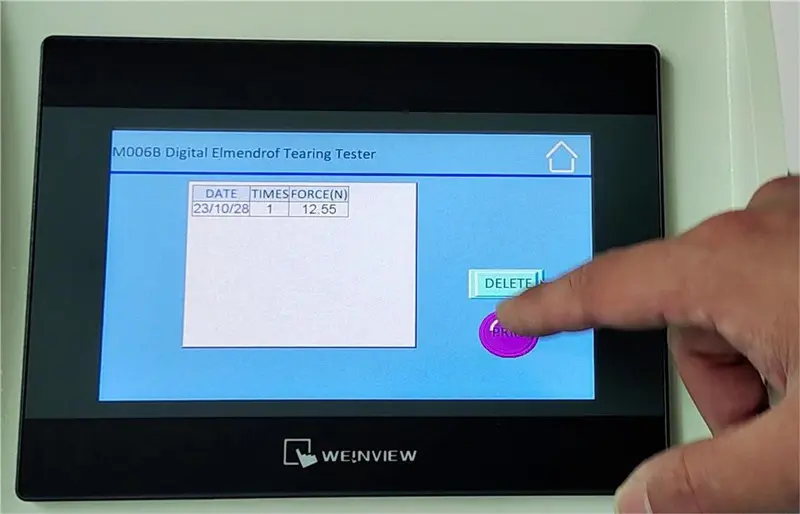

Memory |

Capability to save standard and custom made test methods |

|

Software |

Included with analysis and results output software, series of testing weights with highest capacity and pendulum kit |

|

Power supply |

AC 220V 50/60HZ 100W |

|

Dimensions |

440×500×600mm(L x W x H) |

|

Weight |

50kg |

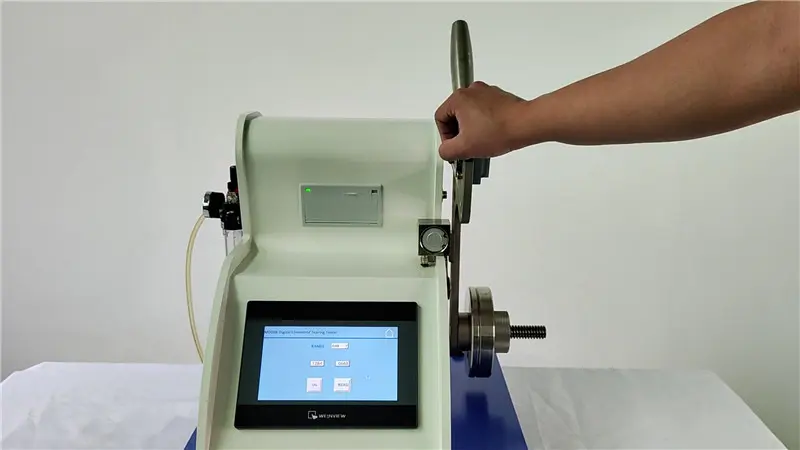

Product Details

Production Processes

Scenarios of Use

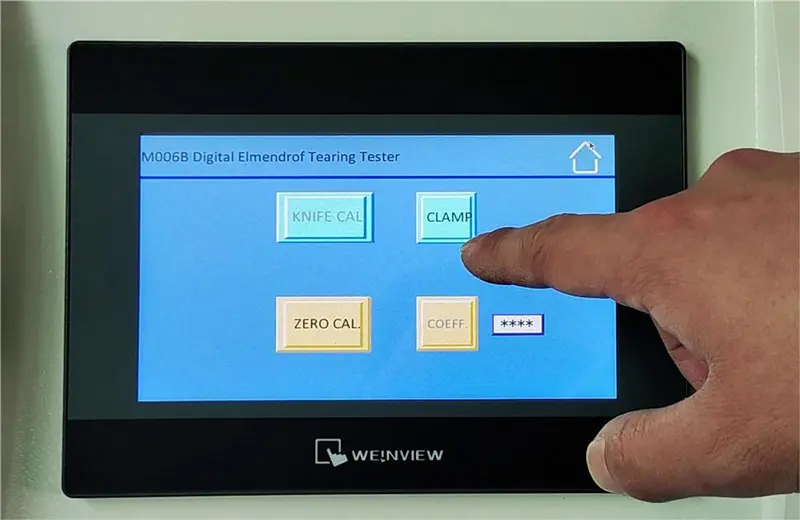

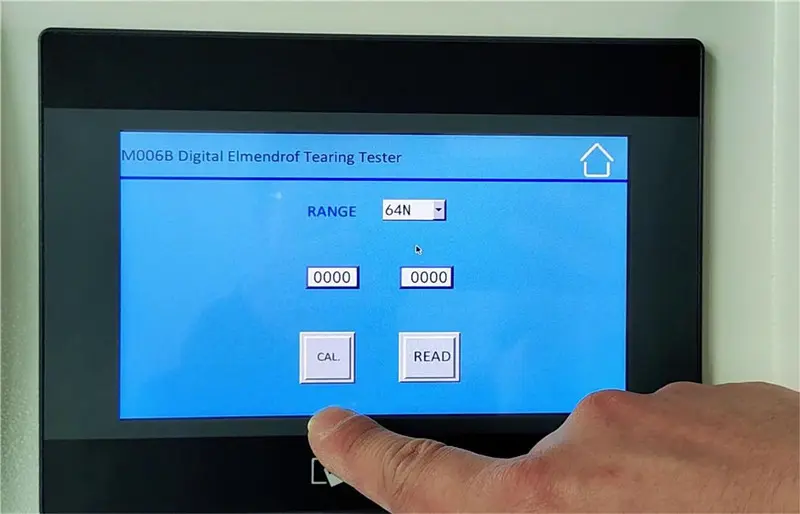

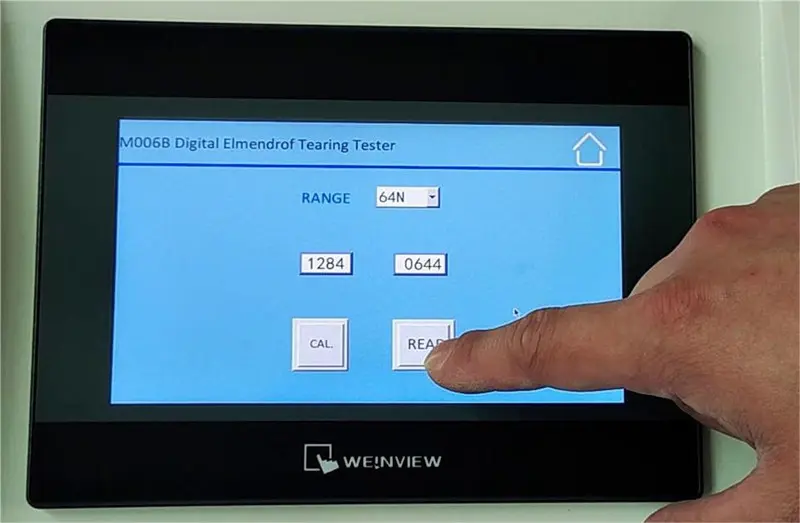

Operation

Transportation

Home

Home