- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

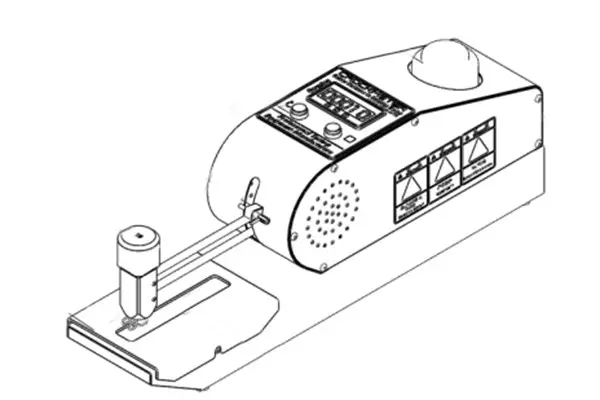

Single Column Universal Tensile Testing Machine Tensile Compression Tester M002A

Overview

Universal testing machine is most commonly used for quality control, inspection, physical test, mechanics research, material development and production environment. The testing is in a tensile or compression mode in a single frame or dual column. Extra test functions include tension, compression, bend, shear, bonding strength, break strength, peeling, tearing, cyclic and flexure, etc.

Application

Standards

ISO13934.1, ASTM D5034, GB/T19976, FZ/T80007.1, BS 2543, M&S P11, JIS L1096, etc.

Key Parameters

|

Model |

M002A-1 |

M002A-2 |

|

Stretch speed |

0.001-500mm/min |

0.001-1000mm/min |

|

Max. Capacity |

100N, 200N, 500N,1KN, 2KN, 2.5KN |

|

|

Effective stroke |

600mm |

|

|

Test Method |

CRE Principle (Constant Rate of Elongation) |

|

|

Test force range |

Full stroke 1% ~ 100% |

|

|

Force Accuracy |

≤±0.2% F· S |

|

|

Sample clamp mode |

Manual , pneumatic clamp |

|

|

Stop Mode |

Overload Stop, Emergency Stop Button, Specimen Damage Automatic Stop, Upper & Lower Limit Set Automatic Stop, Automatic Return Function |

|

|

Protection measures |

a. Beam’s upper and lower limit protective device

b. Clamp defend touch protective device c. Displacement set up & load limit software protective device d. Sensor overload protection e. Sample load software protection f. Overcurrent & overvoltage protection g. Real time monitor for main parts. |

|

|

Machine Drive |

Servo Motor Drive, Synchronous Wheel and Precision Ball Screw Drive |

|

|

Connection |

Available to connect with pad, WIFI or cellphone to control instrument | |

|

Power Supply |

AC 220V 50/60HZ 500W |

|

|

Dimensions(WxDxH) |

670 x 480 x 1440 mm |

|

|

Weight |

120kg |

|

Product Details

Production Processes

Scenarios of Use

Operation

Enter test interface

Turn on the power supply of tensile tester,open the control software, enter TEST interface.

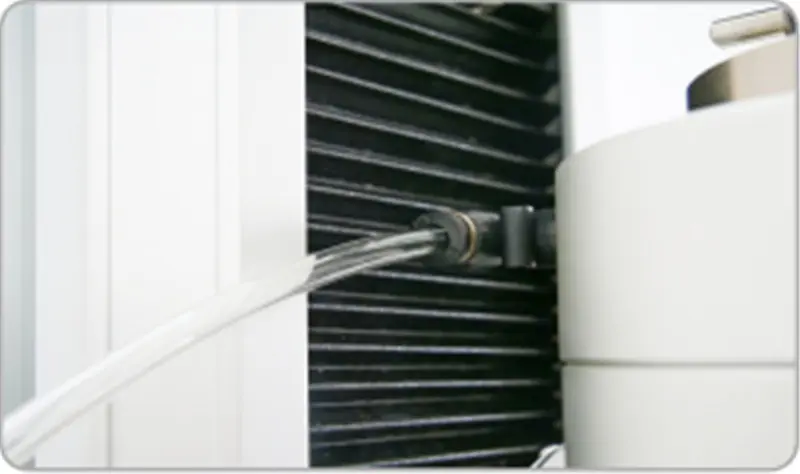

Connect air source

After the upper and lower clamps are installed, use pipes to connect the air compressor and the air holes of the clamps.

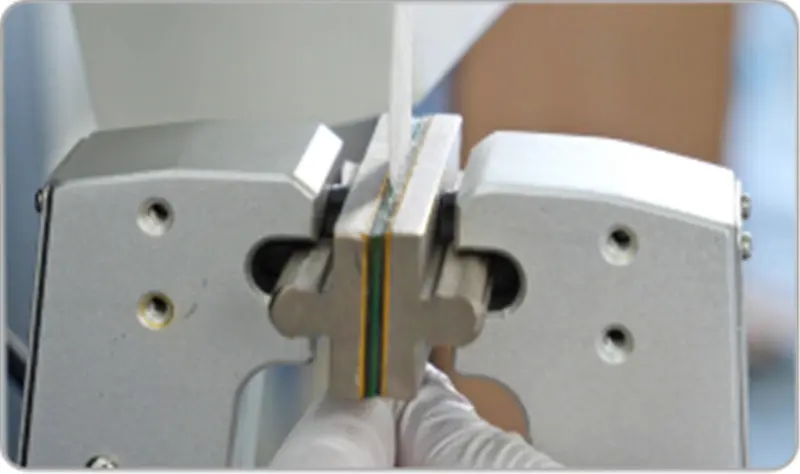

Upper clamp

Put the upper end of the sample into the upper clamp and clamp the sample by pressing the foot switch.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home