- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

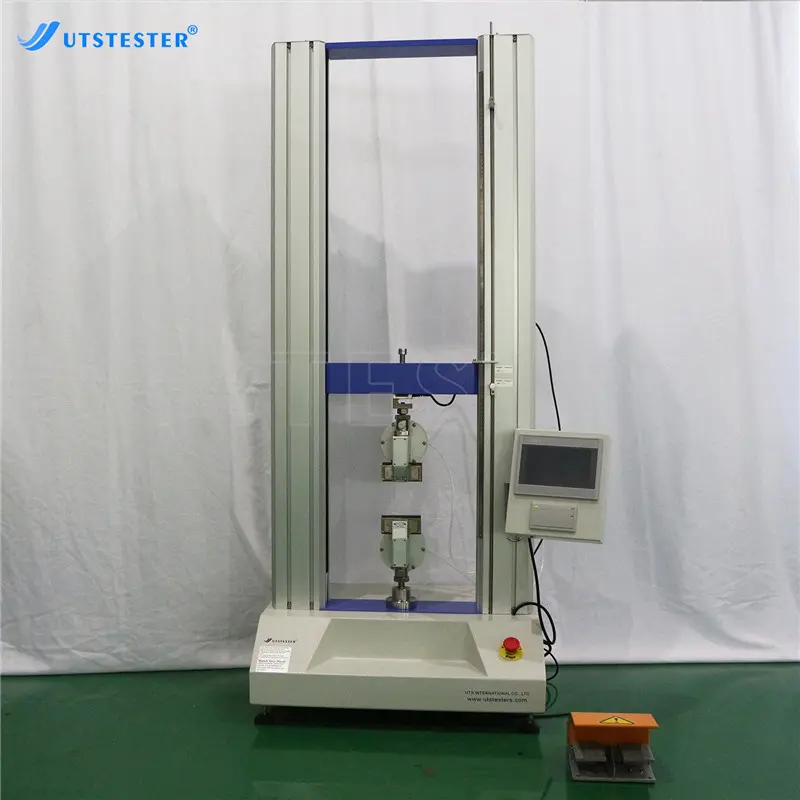

Microcomputer Controlled Universal Testing Machine Strength Testing Machine M001

Overview

Application

Standards

Key Parameters

|

Model |

M001-1 |

M001-2 |

|

Stroke Space |

1100mm(exclude clamps) |

900mm(exclude clamps) |

|

Max. Capacity |

500N 1000N 2500N 5000N 10000N |

|

|

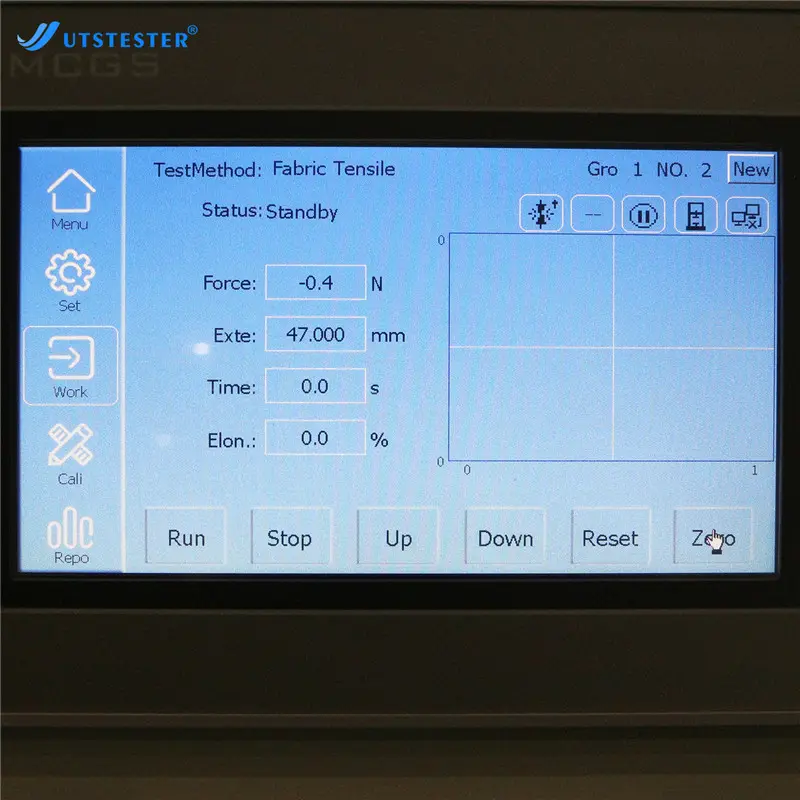

Test Method |

CRE Principle (Constant Rate of Elongation) |

|

|

Display Mode |

Computer Display Mode |

|

|

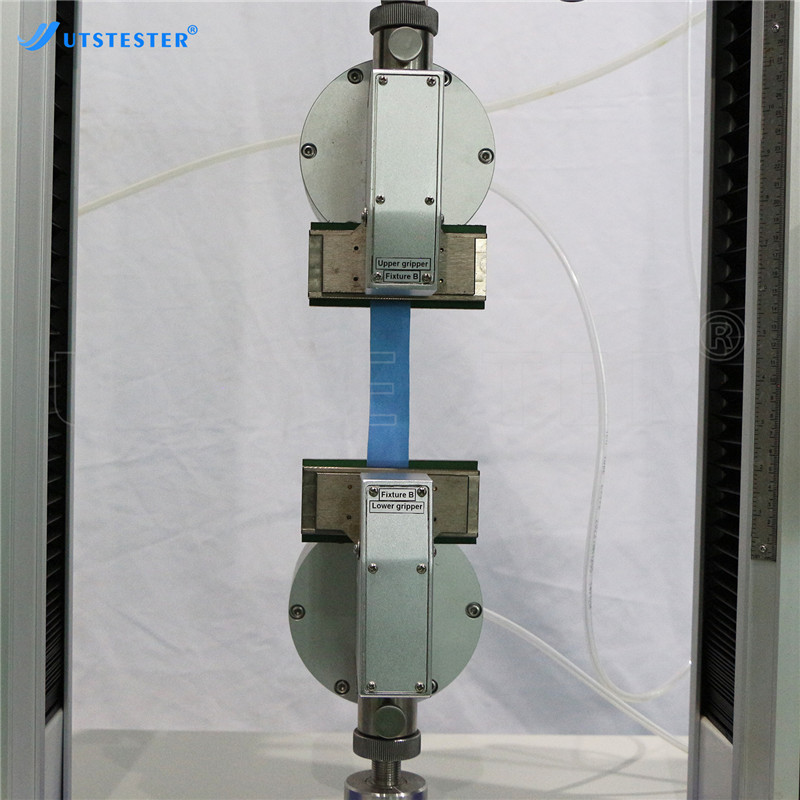

Sample clamp mode |

Manual , pneumatic clamp |

|

|

Effective collective frequency |

1000 times/ second |

|

|

Resolution of Force |

1/100,000 |

|

|

Accuracy of Force |

≤±0.2% F· S |

|

|

Resolution of Stroke |

0.001 mm |

|

|

Test Speed Range |

0.001-1000mm/min Digit speed control, error ≦±1% |

|

|

Gantry Structure Width |

400mm |

|

|

Stop Mode |

Overload Stop, Emergency Stop Button, Specimen Damage Automatic Stop, Upper & Lower Limit Set Automatic Stop, Automatic Return Function |

|

|

Protection measures |

|

|

|

Machine Drive |

Servo Motor Drive, Synchronous Wheel and Precision Ball Screw Drive |

|

|

Connection |

Available to connect with pad, WIFI or cellphone to control instrument | |

|

Power Supply |

AC 220V 50/60HZ 10A |

|

|

Dimensions(WxDxH) |

820x630x1800mm |

|

|

Weight |

120kg |

|

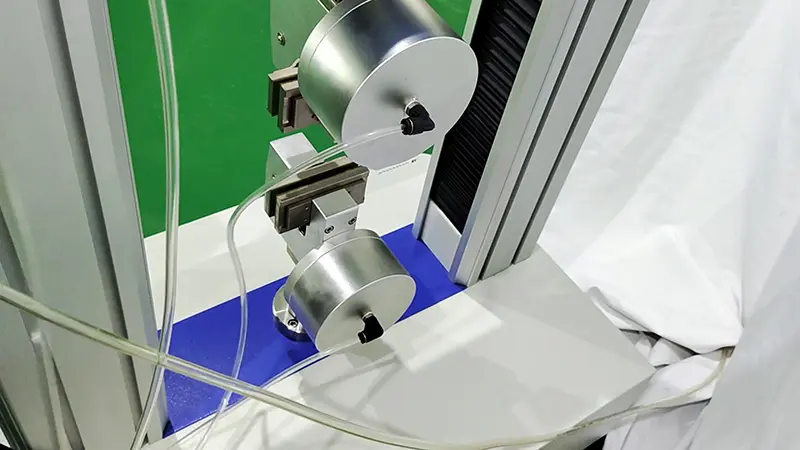

Product Details

Production Processes

Scenarios of Use

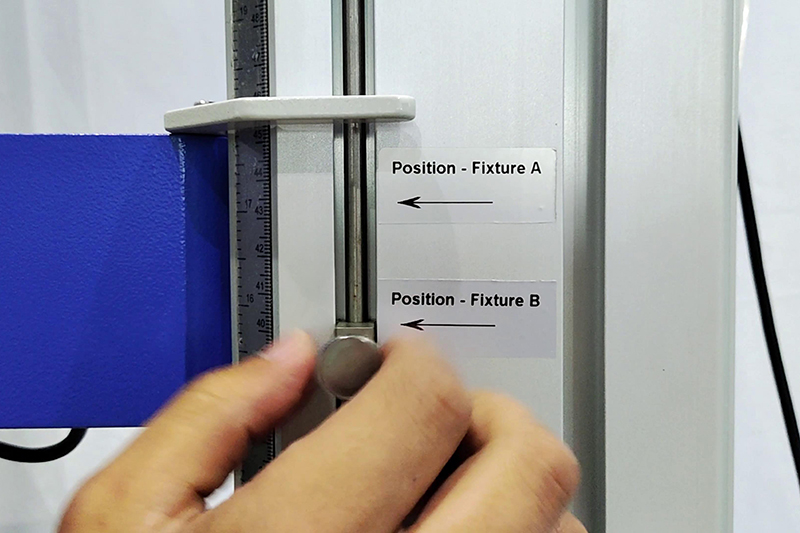

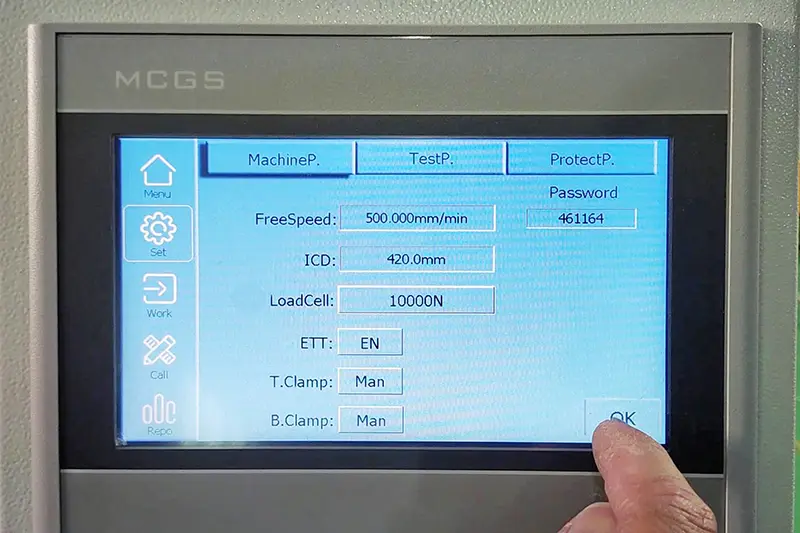

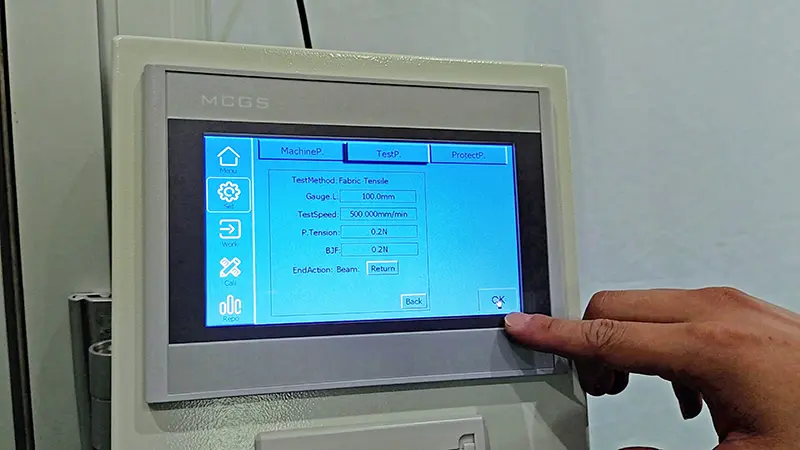

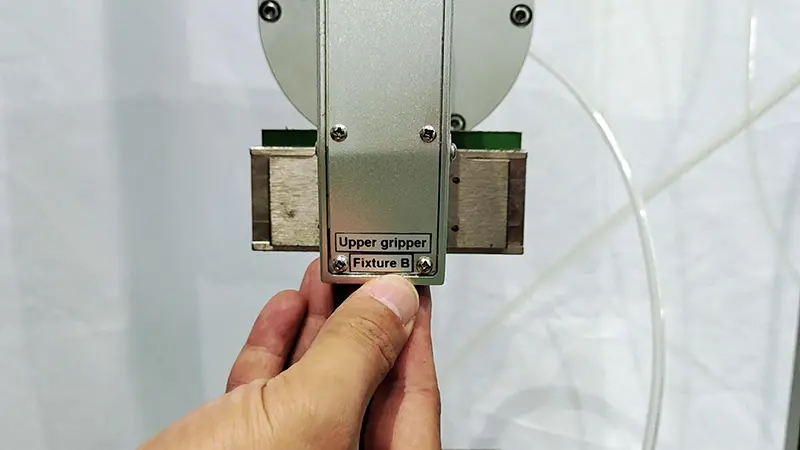

Operation

Enter test interface

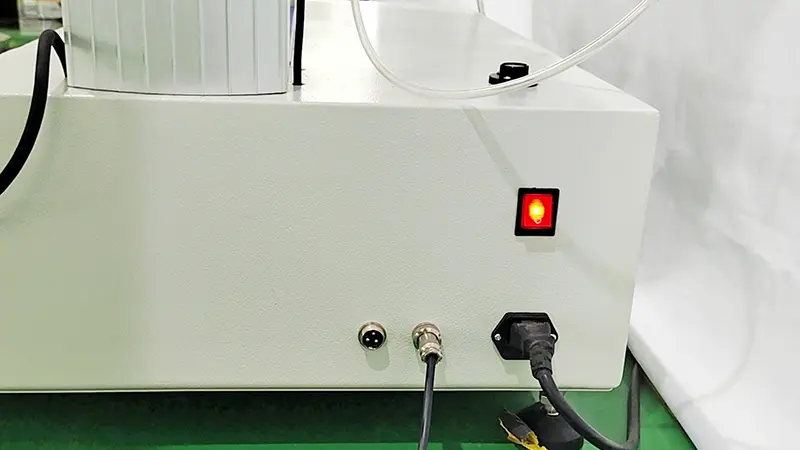

Connect air source

Upper clamp

Transportation

Home

Home