- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

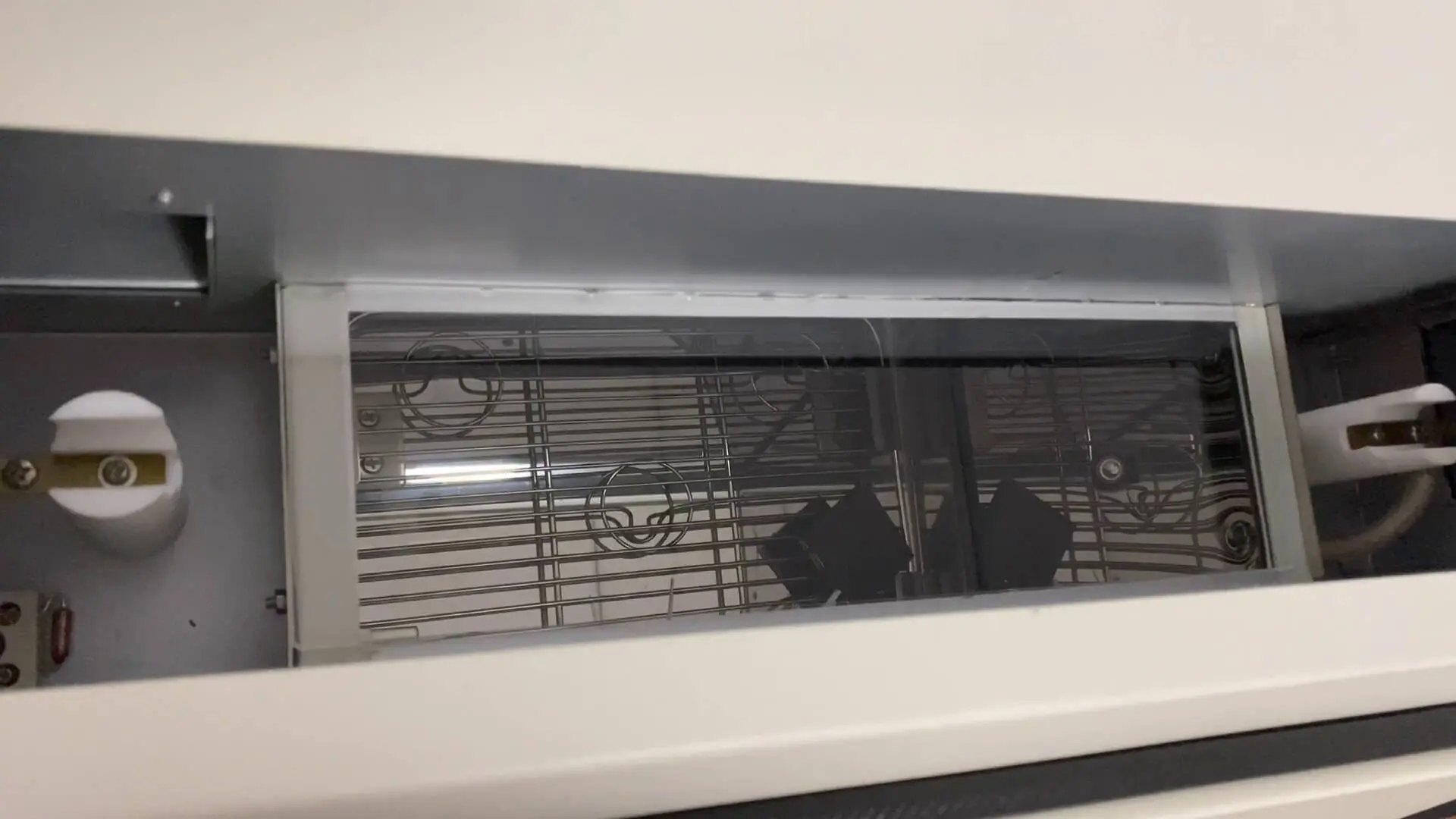

Composite Geotextiles Effective Pore Size Tester Geotextiles Effective Opening Size Tester-Dry Sieving Method MA07N

Overview

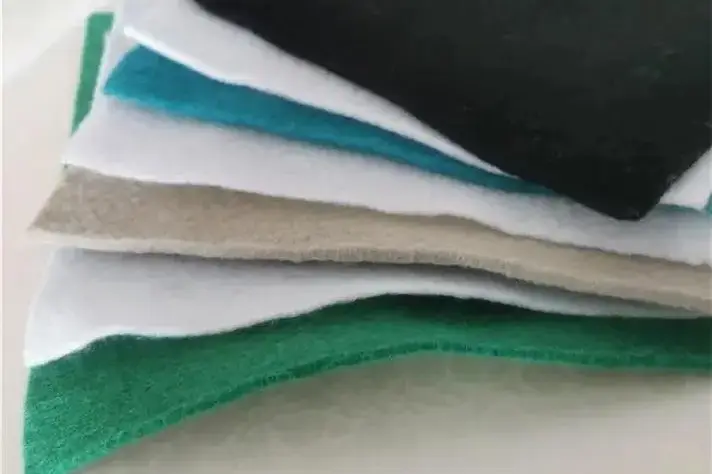

For the determination of the effective pore size of geotextiles and composite geotextiles by the dry sieve method.

Application

Standards

JTG E50-2006, SL 235-2012, GB/T 14799-2005, BS 6906, ASTM D4751

Key Parameters

|

Model |

MA07N |

|

Display |

4.3 inch true color touch screen, English menu operation |

|

Combined set of sieve specifications |

Ф 198±2 mm 5 pieces |

|

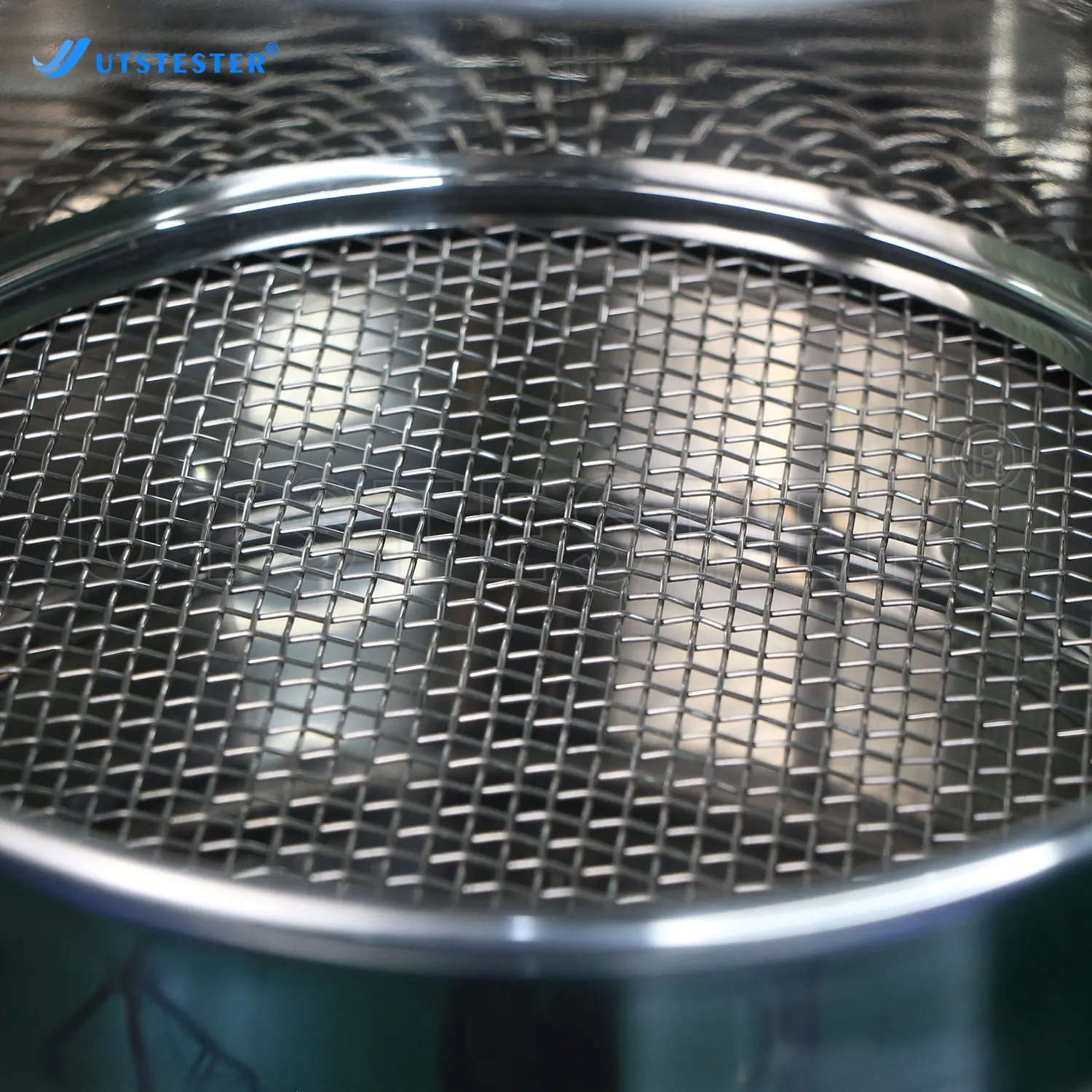

Stainless steel leak-proof sieve frame |

Ф 200 * 53mm |

|

Sieve disk specifications |

Ф 200 * 45 mm 5 (receiving disk and the number of mesh screen 5 sets of 10) |

|

Stainless steel set of sieve holding ring |

Ф 198 ± 2 mm 5 only |

|

The number of test |

5 groups / times, can be done at the same time 5 groups of specimens |

|

Rotary radius |

12±1 mm |

|

The number of vibration |

147 ± 10 mm times / min |

|

Up and down amplitude stroke |

8 ± 2 mm |

|

Time setting |

0-999 hours 59 minutes 59 seconds |

|

Power supply |

AC 220V 50Hz 370W |

|

Dimension |

550×750×1010mm |

|

Weight |

160kg |

Product Details

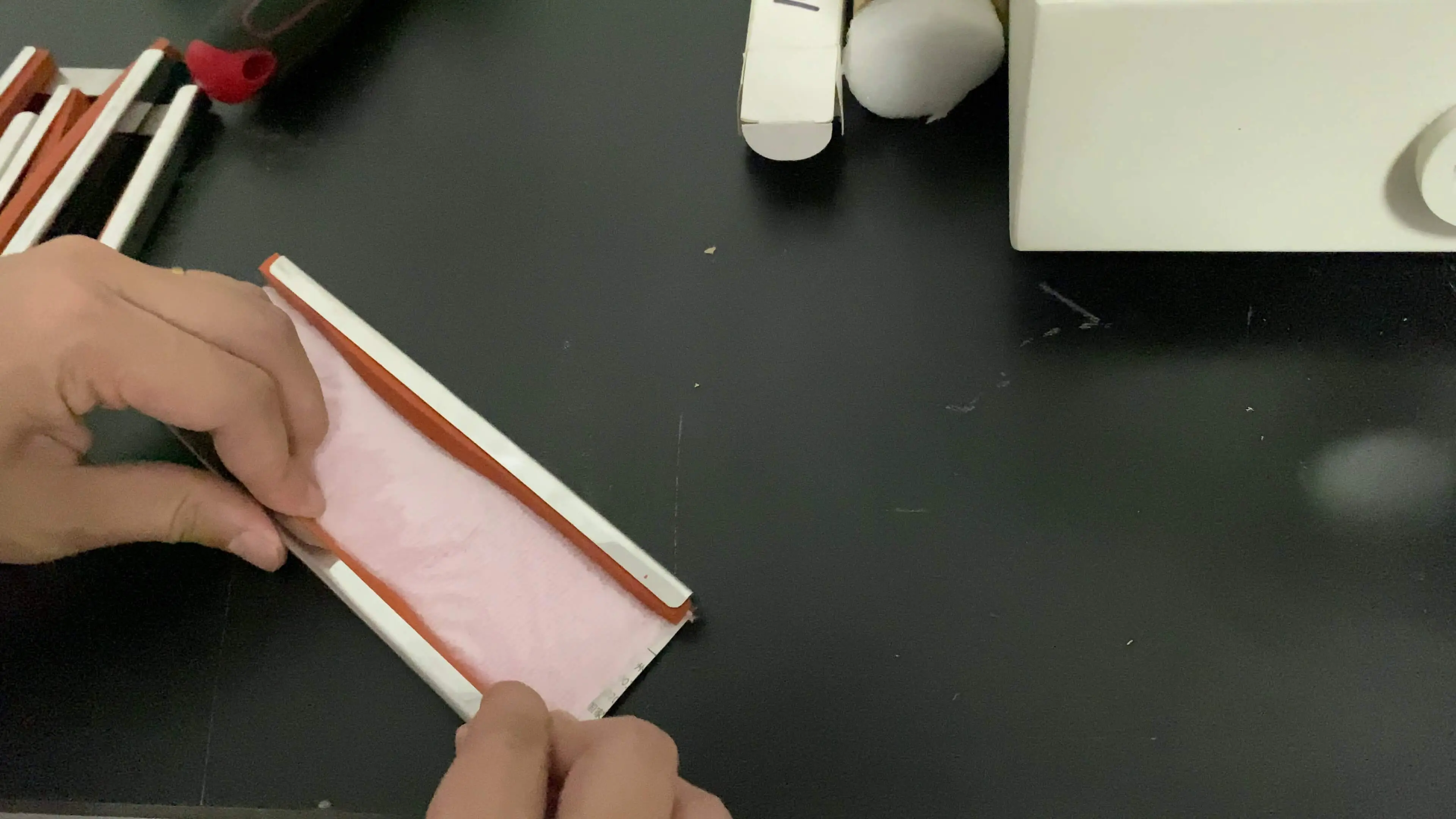

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home