- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Yarn Testing Machine Heat Shrinkage Test Machine Thermal Shrinkage Tester Y025

Overview

The dry heat shrink tester is specially designed and manufactured to adapt to the new national standards for impregnated curtain fabrics and the rapid development of the tire industry. Due to the increasing updates in tire manufacturing technology, the size of the dry heat shrinkage rate of the tire cord, which serves as the tire skeleton material, directly affects the stability of tire size and the uniformity of quality after vulcanization and shaping. Therefore, tire companies are paying more and more attention to the indicators of dry heat shrinkage and shrinkage force of the cord cord (especially prominent in foreign and foreign enterprises). At the same time, from the perspective of the new national standard for impregnated cord fabric, The secondary indicators specified in the 88 standard have been treated as primary indicators, and the evaluation requirements have been correspondingly increased.

The Y025 dry heat shrink tester produced by our company is a fully electronic measuring instrument with a highly automated testing process, which can fully meet the needs of users in this regard.

Usage:

The Y025 type dry heat shrinkage tester is used to test the dry heat shrinkage rate and dry heat shrinkage force of impregnated polyester cord, impregnated yarn, cord and curtain, and polyester industrial filament.

Application

Standards

HG/T 2821.2-2012 Dipped polyester cord for V-belts and multi wedge belts Part 2: Flexible cord

GB16604-2017 Polyester Industrial Filament

GB/T 30312-2013 Test method for thermal shrinkage of impregnated yarns, ropes, and cords

GB T 9101-2017 Nylon 66 impregnated curtain fabric

Key Parameters

1. Usage conditions: Environmental temperature: -10~+40 ℃; Relative humidity: 45% to 85%; No vibration;

2. Temperature control range: room temperature~250 ℃;

3. Temperature control accuracy: ± 0.1 ℃;

4. Shrinkage measurement accuracy (resolution): 0.01% (100% for 250mm);

5. Shrinkage force measurement accuracy (resolution): 0.01N

6. Measurement range of contraction force: 0-50N (range can be changed according to user needs);

7. Test time: 1-60 minutes;

8. Operating voltage: AC220V, 50Hz;

9. Maximum heating power: 1000W;

10. LCD touch screen operation, equipped with a micro printer, convenient for printing test reports.

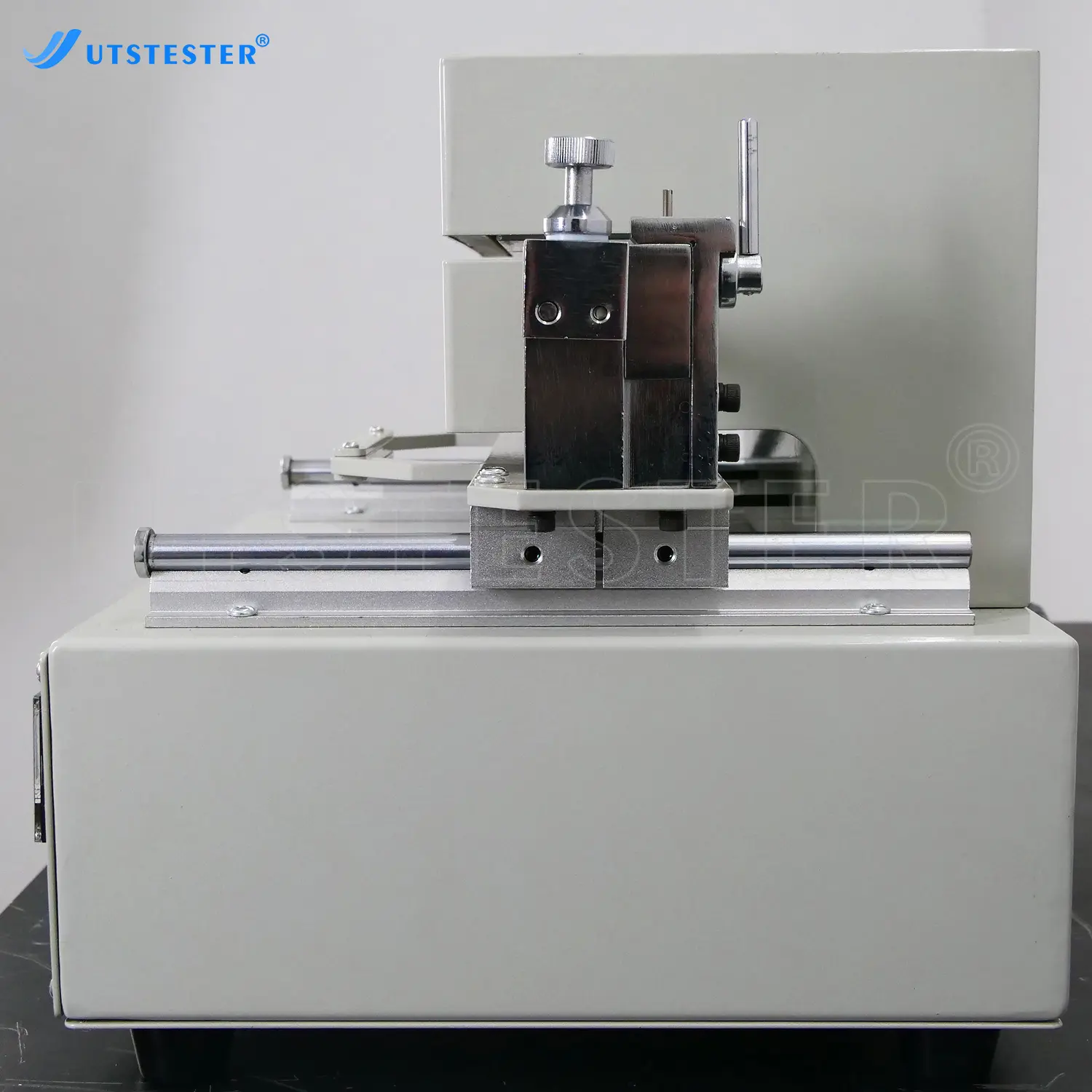

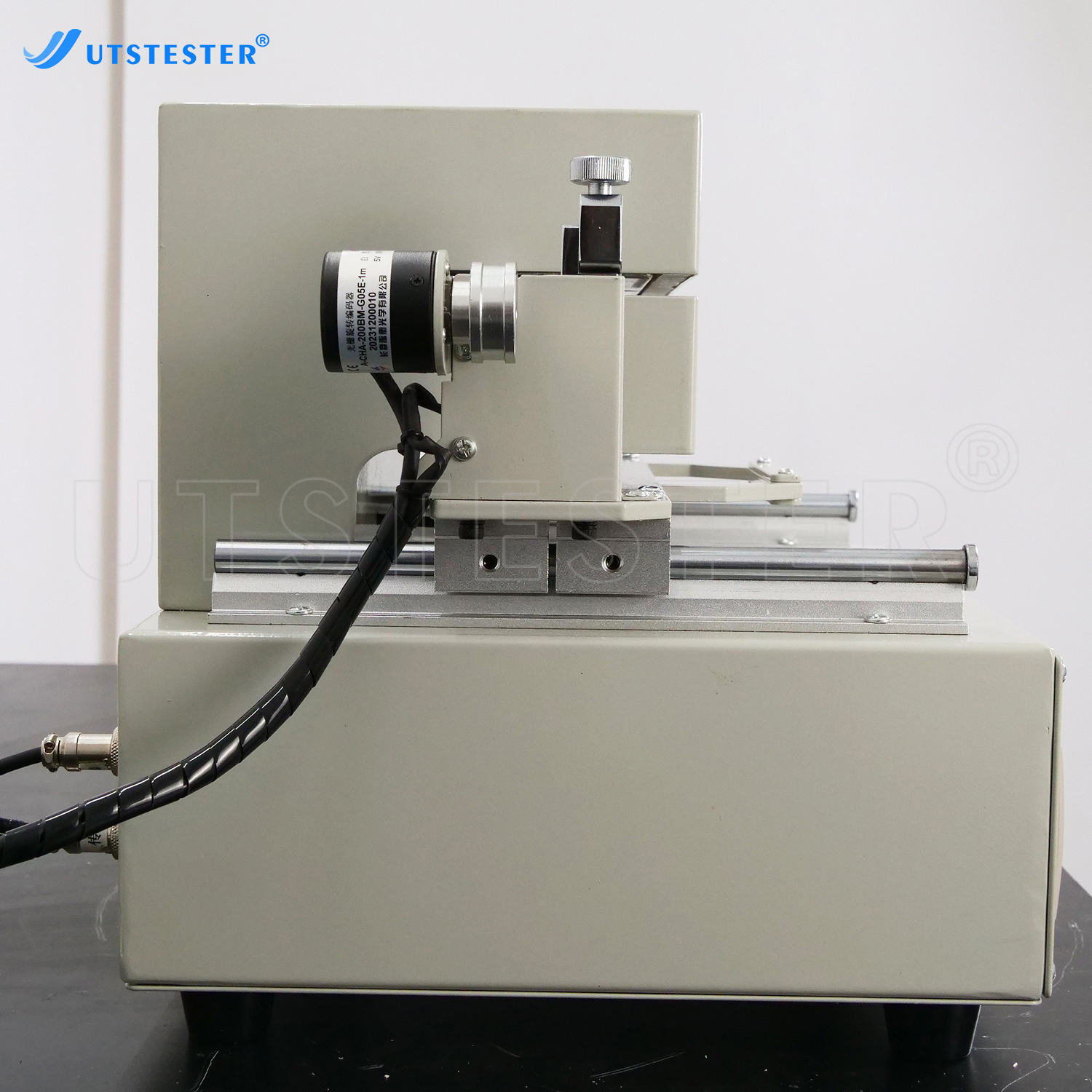

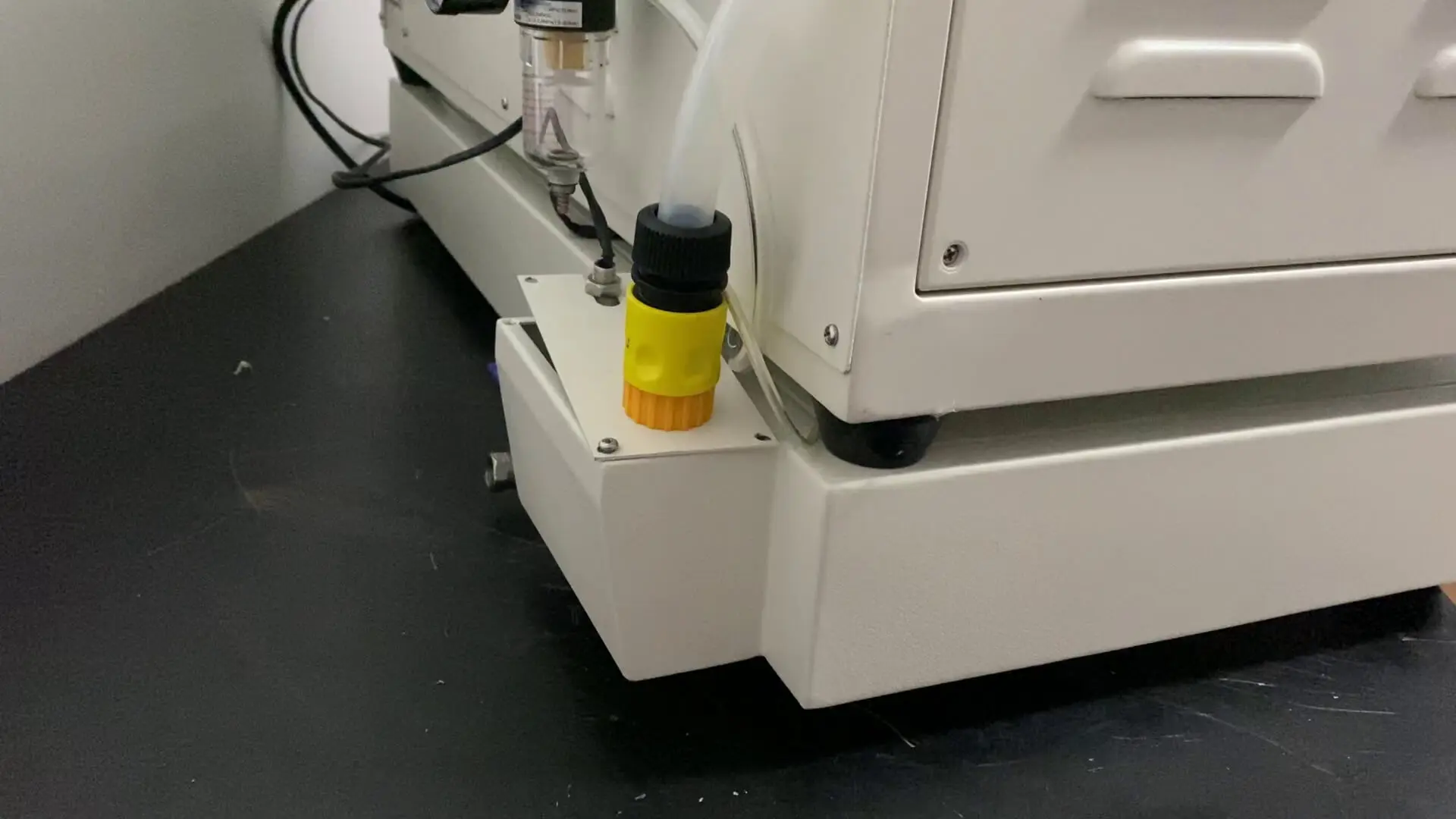

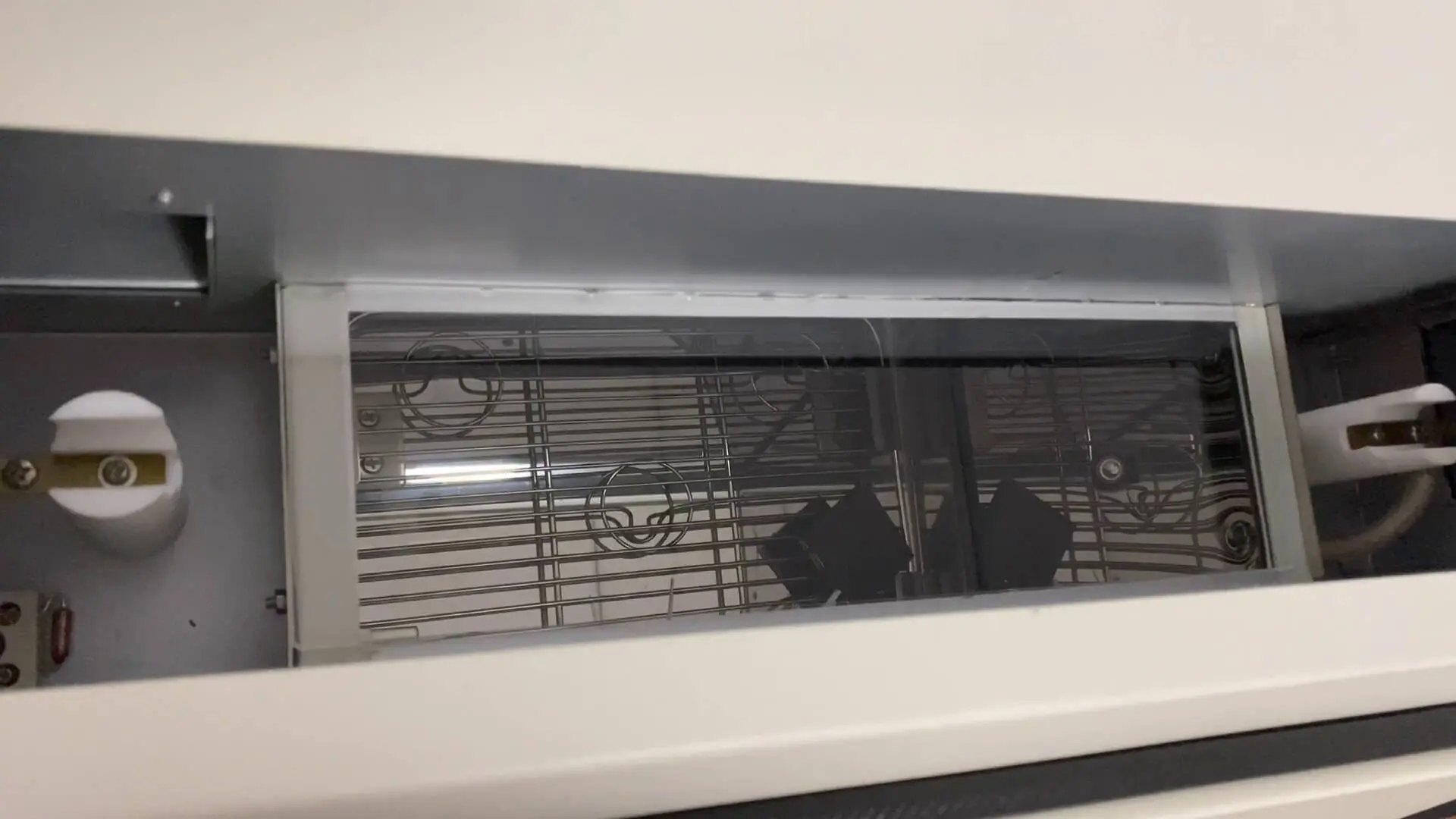

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

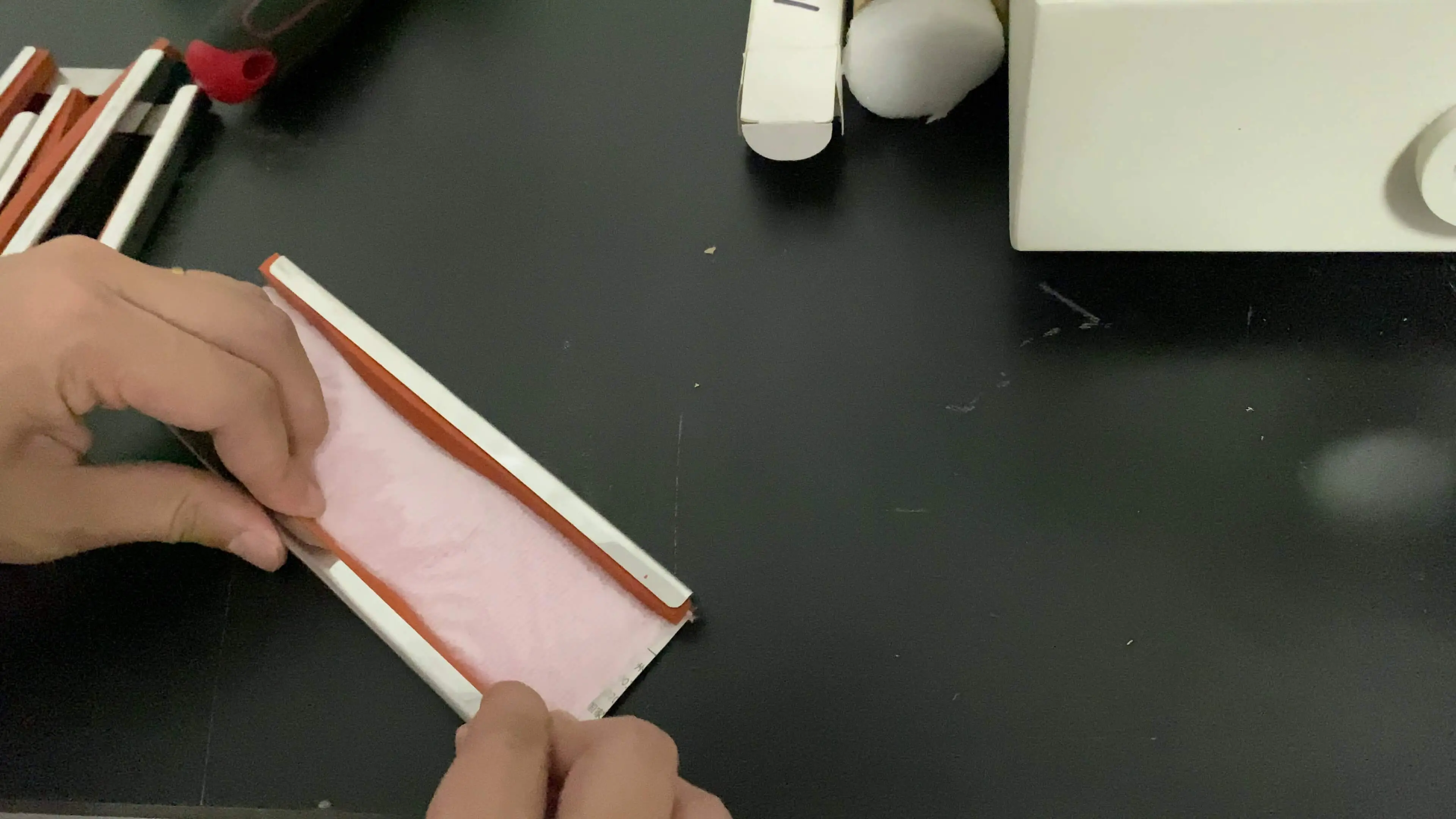

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home