- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

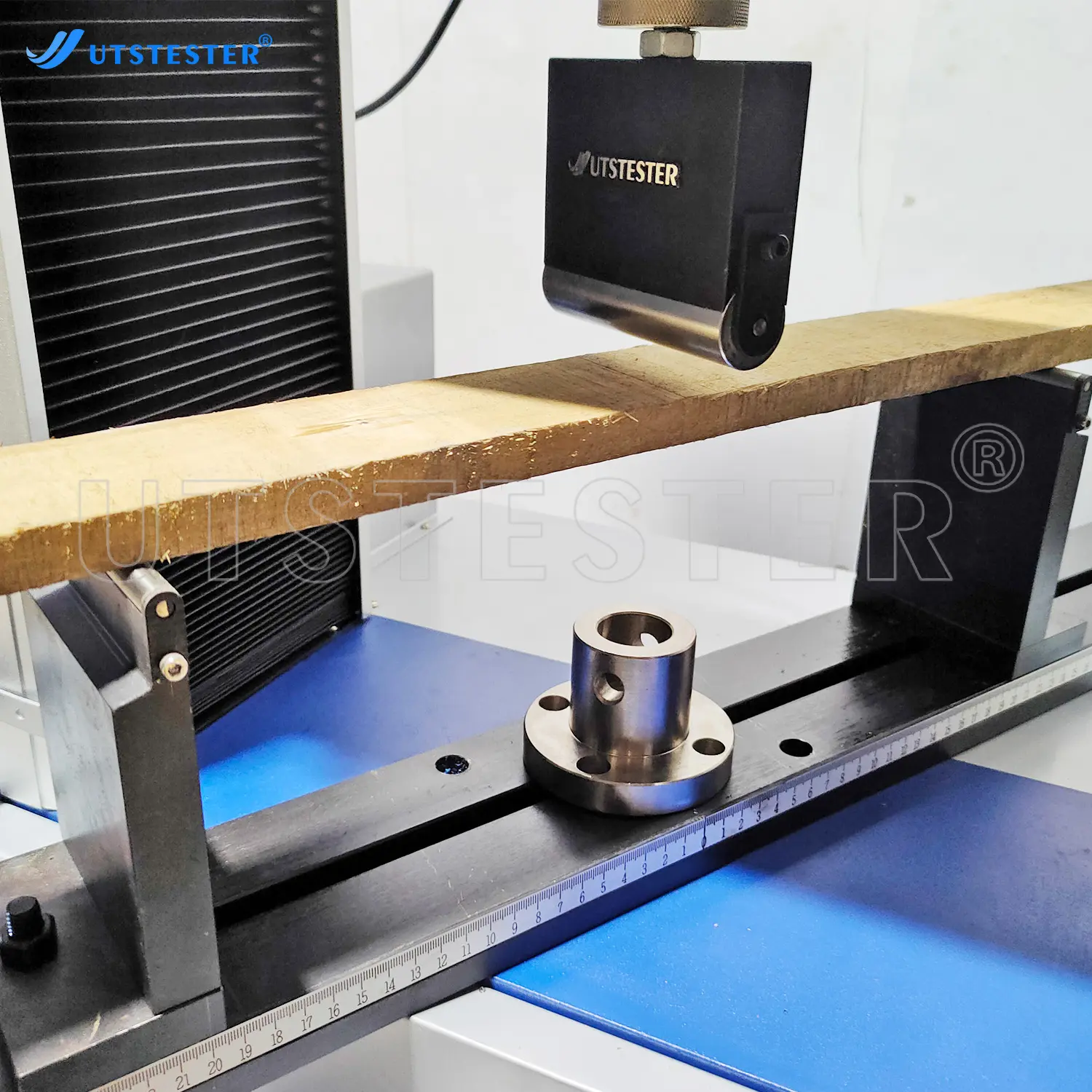

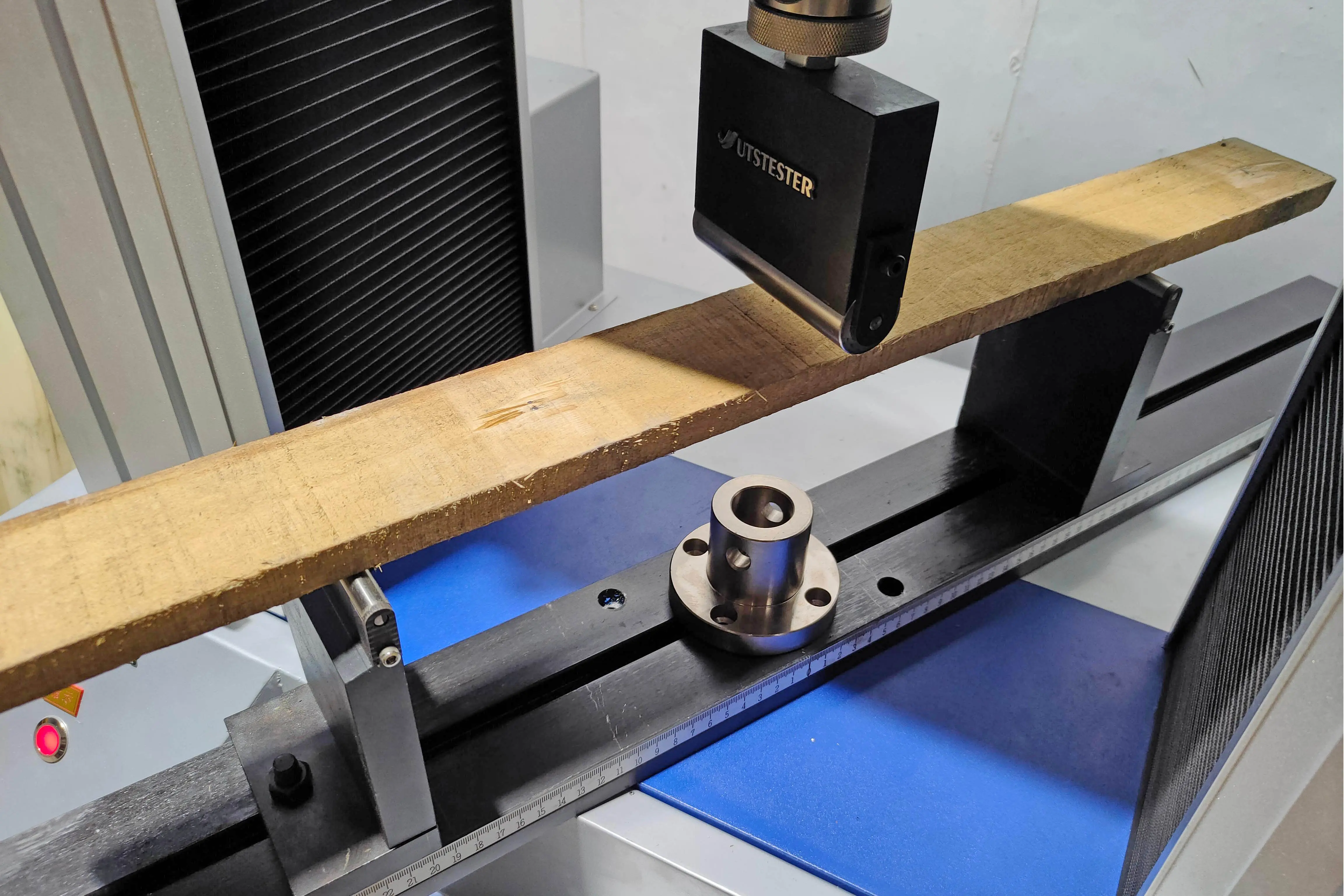

Universal Testing Equipment Automatic Tensile and Compression Testing Machines H001N

Overview

Tensile testing is used in many industries for research, quality and process control. It is designed to determine tensile, compression, bending, shearing force, bonding force, peeling, tearing test, etc, for steel wire, leather, rubber, plastic, textile, metal, nylon thread, paper and materials of footwear, packaging, aviation, petrochemical, construction, electrical, vehicle, etc.

Application

Standards

SATRA TM5, TM53, TM52, TM51, TM108, TM113, TM117, TM118, TM120, TM123, TM149, TM162, TM401, TM 411, TM 410

ISO 34-1, ISO 36, ISO 37, ISO 3377-1, ISO 3377-2, ISO 11644, ISO 20866, ISO 20867, ISO19957, ISO20874, ISO22650, ISO 19958, ISO20344-5.2.4, ISO 20345-5.3.1.2, ISO17698, ISO20875, ISO 22777, ISO 22776, ISO 22654, ISO 20863, ISO20876, ISO17695, ISO17697, ISO 17708, ISO 17696, ISO17706, ISO 22650

AS/NZS 2210.2-5.2.4, DIN 53331

ASTMD 882,ASTMD5034 ,ASTMD 751/2209 /412/624 FIA 1206; BS 5131- 3.7, 5.11, 5.13 , BS 5131-2.6

Key Parameters

|

Model |

H001N |

|

Test Speed |

0.1-1000mm/min |

|

Max. Capacity |

5KN,10KN, 20KN, 30KN, 50KN, 100KN, 200KN, 300KN etc. |

|

Unit |

kgf, lbf , N , kN, kPa, MPa |

|

Load degree of decomposition |

1/200,000 |

|

Load accuracy |

±0.25% |

|

Speed accurate |

±0.1% |

|

Effective width |

410mm |

|

Displacement accuracy |

0.04mm |

|

Effective stroke |

1100mm (Exclude clamps)(Customized) |

|

Motor |

Servo Motor |

|

Very low maintenance

|

The selected materials, components and machine detail design produces a robust, durable machine with very low maintenance requirements. |

|

Machine protection |

Load cell protection; protection against overload, impact and overtravel; telescopic covers providing additional protection for ballscrews. |

|

Power Supply |

AC 220V 50/60HZ 10A |

|

Dimensions |

660×530×2130mm(WxDxH) |

|

Weight |

163kg |

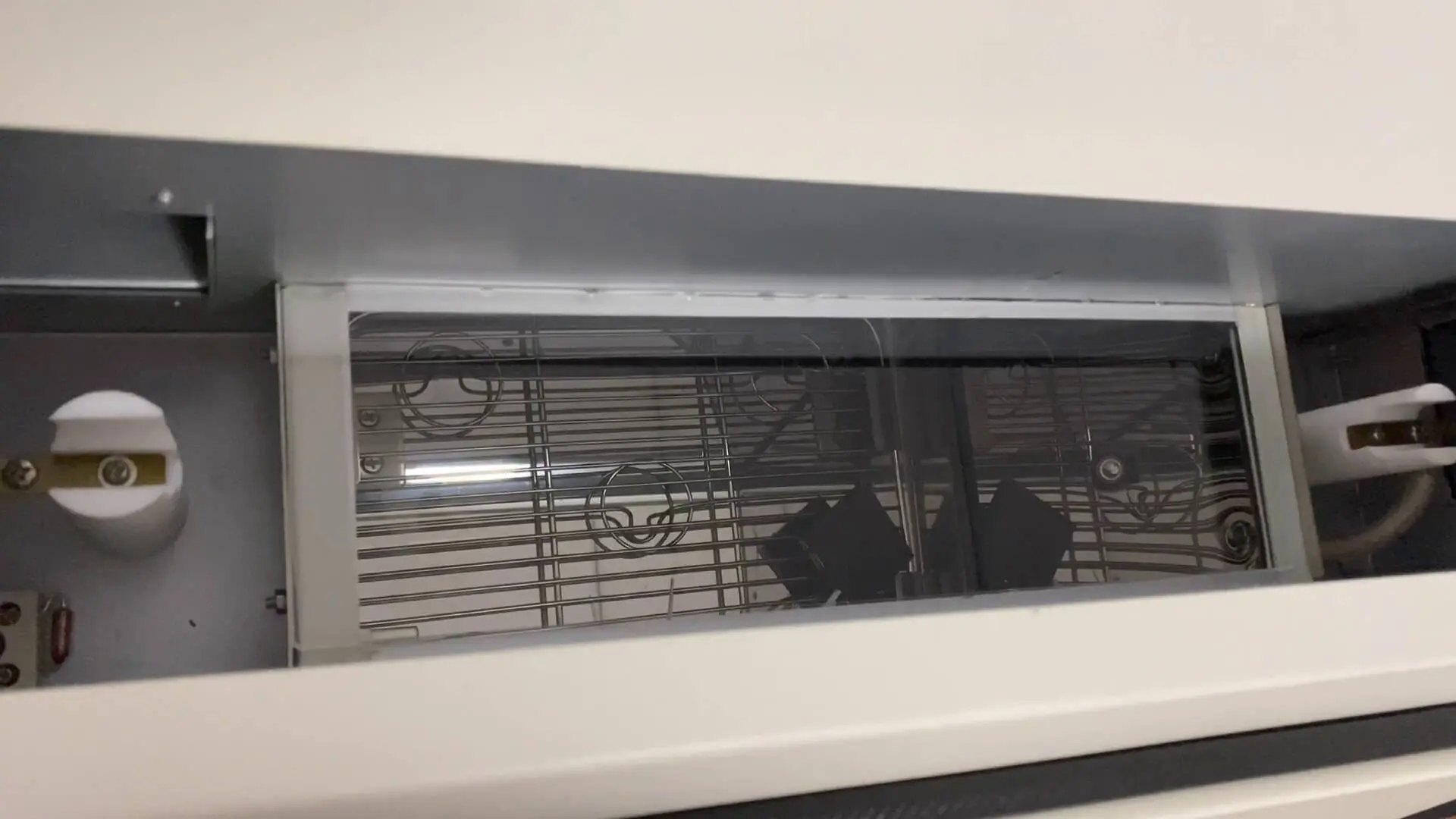

Product Details

Production Processes

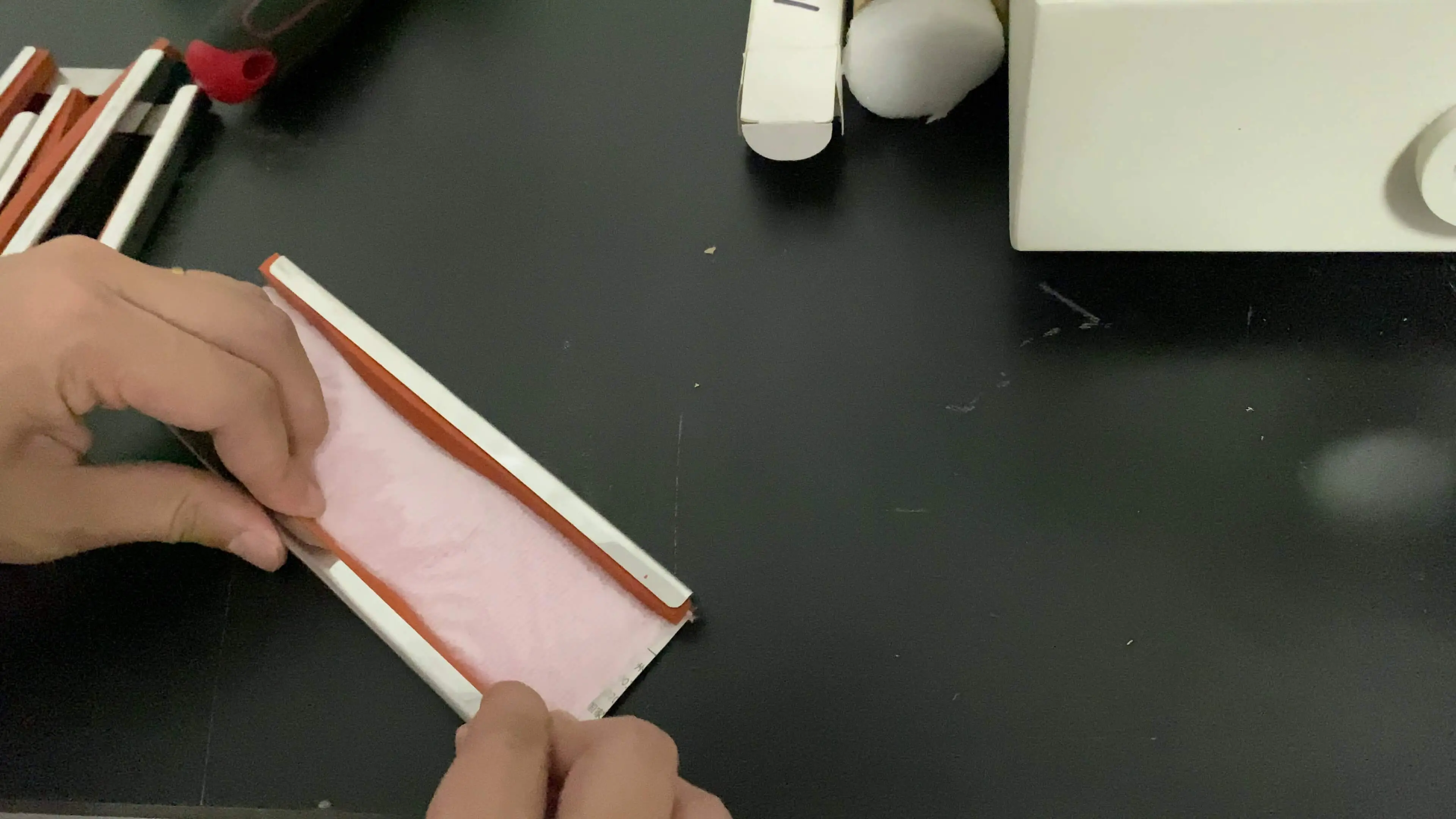

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home