- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Textile Machinery Large Hanging Fabric Combustor M017E

Overview

Application

Standards

Key Parameters

|

Model |

M017E |

|

|

Equipment Performance |

Inner Size |

305W*305*2130H |

|

Outside Size |

655W*315*2550H |

|

|

Flame height adjustment: |

10-400mm |

|

|

Flame angle |

25 degrees |

|

|

Adjustment range of ignition time |

0-99.99sec. |

|

|

Remaining ignition timing range |

0.01s~99.99s |

|

|

Ignition time timer resolution |

0.01s |

|

|

Residual flame, afterburning time resolution |

0.01s |

|

|

Burner |

In accordance with ASTM5025 standard |

|

|

Burner inner diameter |

9.5mm long about 100mm |

|

|

Structure Design |

Outer box material |

1.5mm SUS # 303 stainless steel CNC machining molding |

|

Burner control |

Front and rear directional rail push-in, automatic timing in place |

|

|

Fixture design |

Stainless steel material processing |

|

|

Control System |

Controller |

7-inch color touch screen controller, automatic program control |

|

Ignition mode |

Panel type button automatic ignition |

|

|

Timing mode |

Burner in place automatic timing, hand-held button to record the burning time, designed for fume hood testing |

|

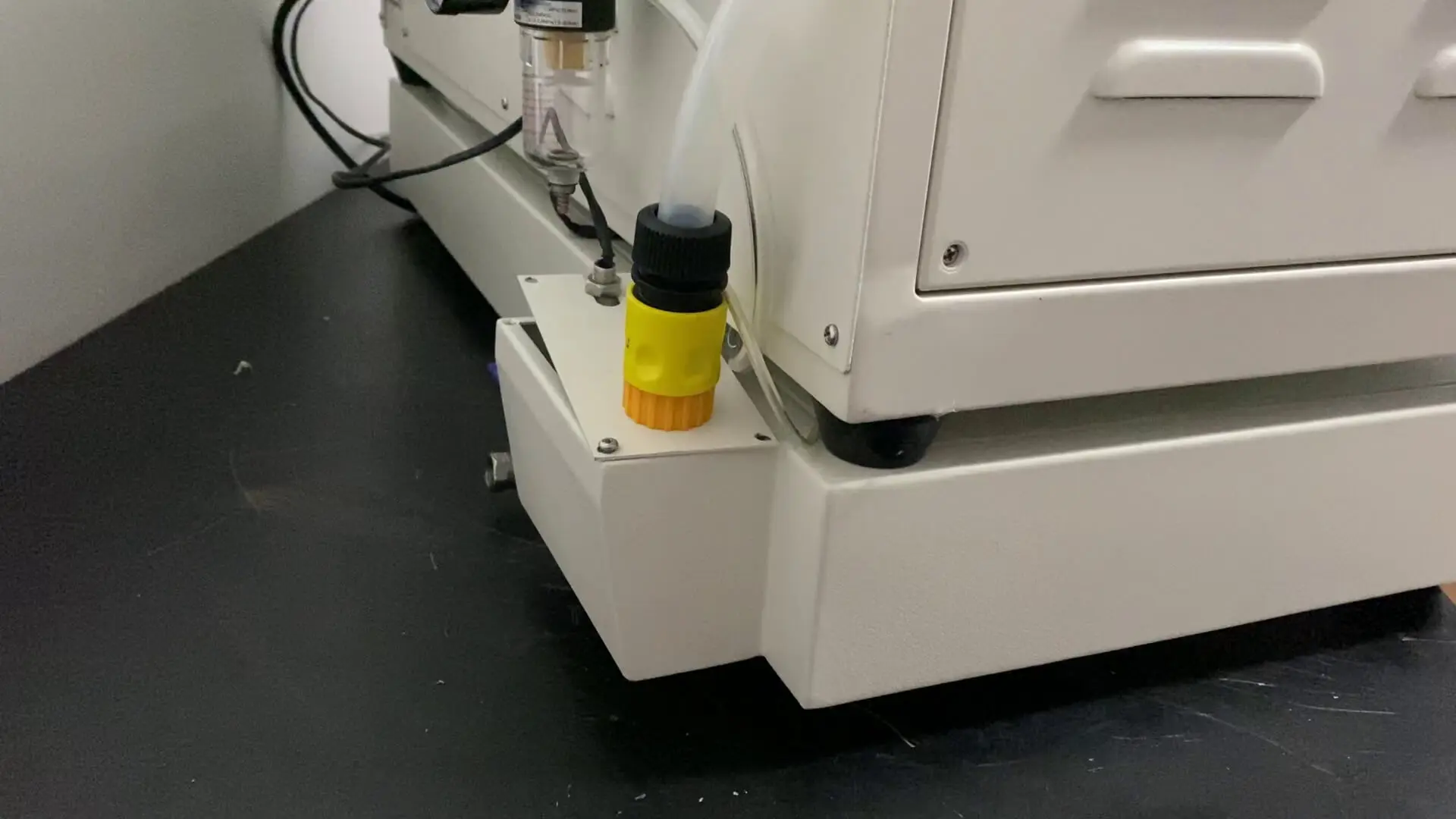

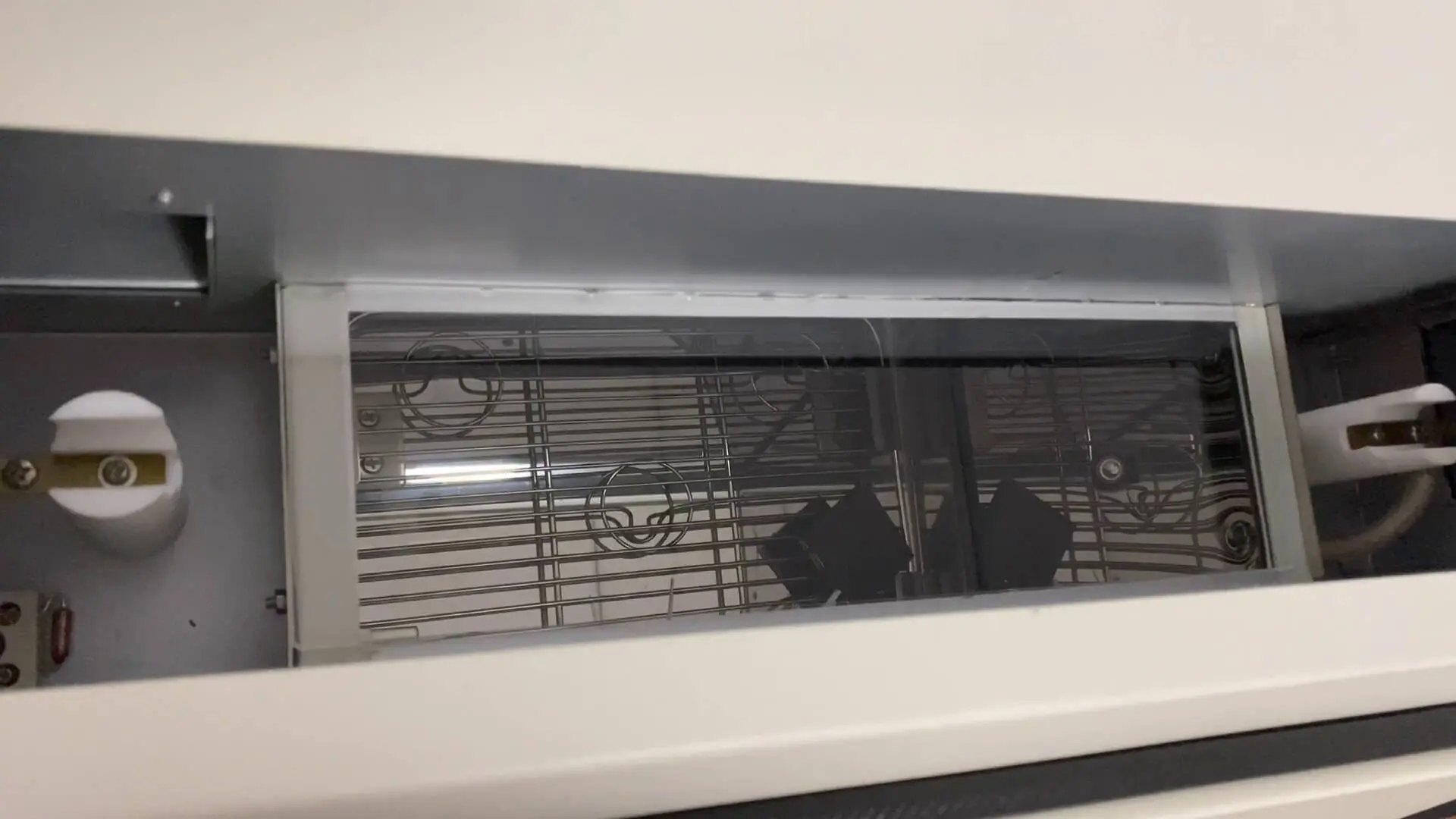

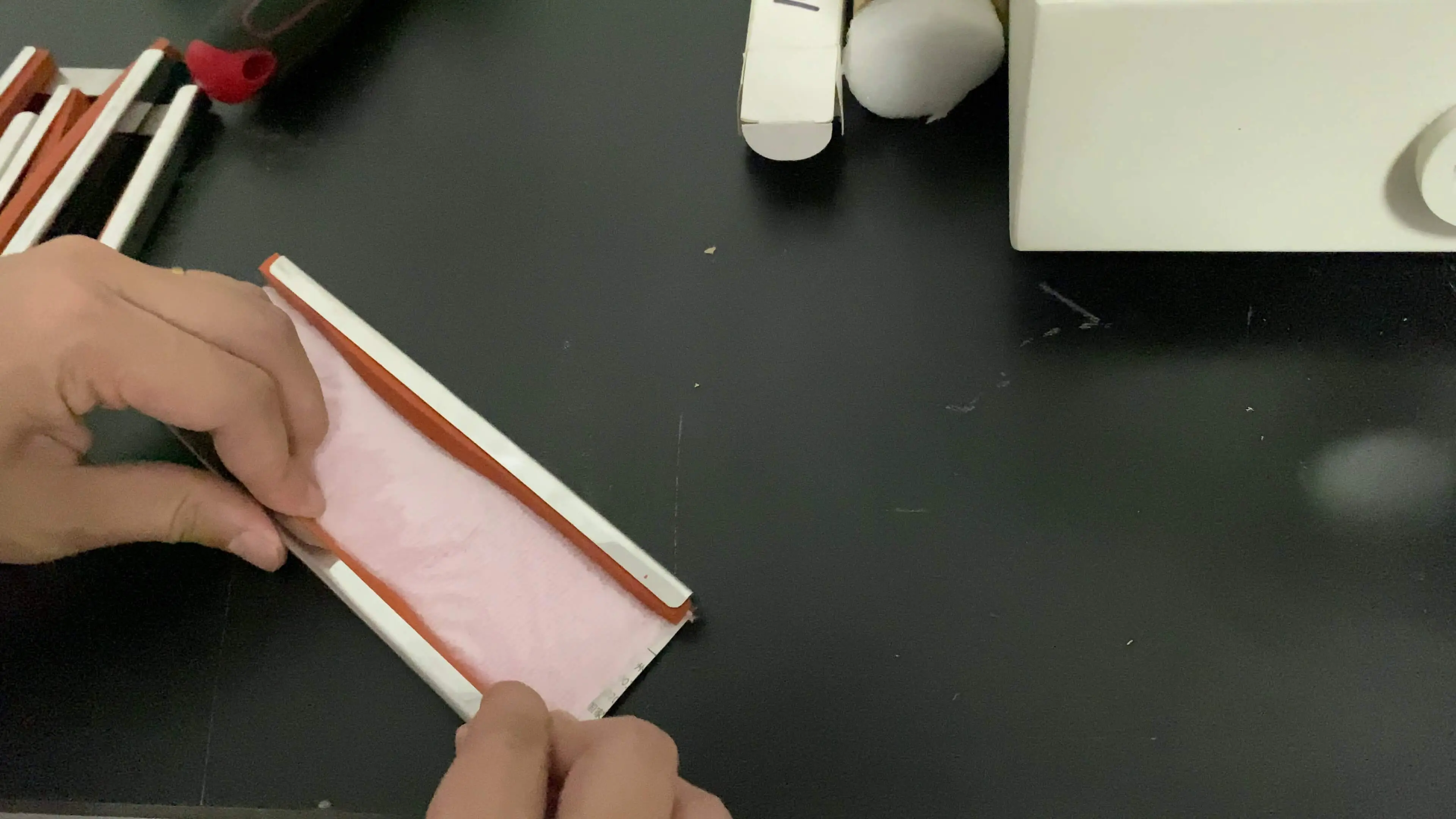

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home