- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Textile Machinery Lab Scale Coating Machine D035C

Overview

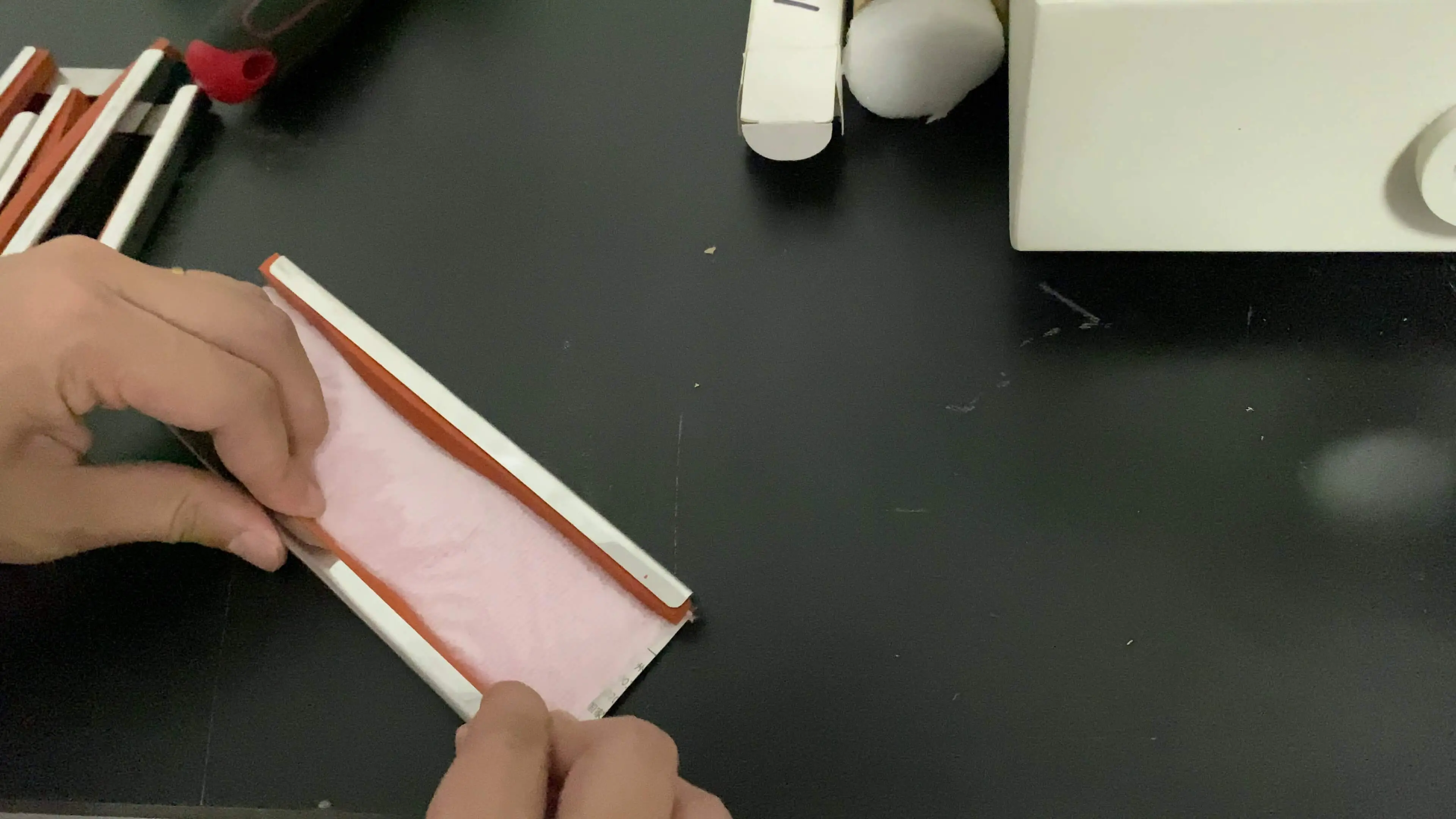

It is convenient to change the coating parameters by changing the position of the high and low of the coating knife, the front Angle of the coating knife and the position of the square idler.

This machine is suitable for finishing the coating of all kinds of textiles and other materials, to ensure the uniformity and stability of coating on different flat materials, and to continuously coating the smooth and flawless test samples.

Application

Standards

Standards

Key Parameters

|

Model |

D035C |

|

|

Roller |

Upper roller |

NBR rubber roll, Shore 70℃ . Roll surface length 1000mm×diameter 165mm Easy to dismantle and replace |

|

|

Bottom roller |

Stainless steel 304 anilox roll. Diamond size: 1.5 × 1.5 ㎜. |

|

Material |

All surfaces of the machine are made of 304 stainless steel |

|

|

Pressure form |

Double cylinders, double pressure regulation, more accurate control. |

|

|

Cleaning |

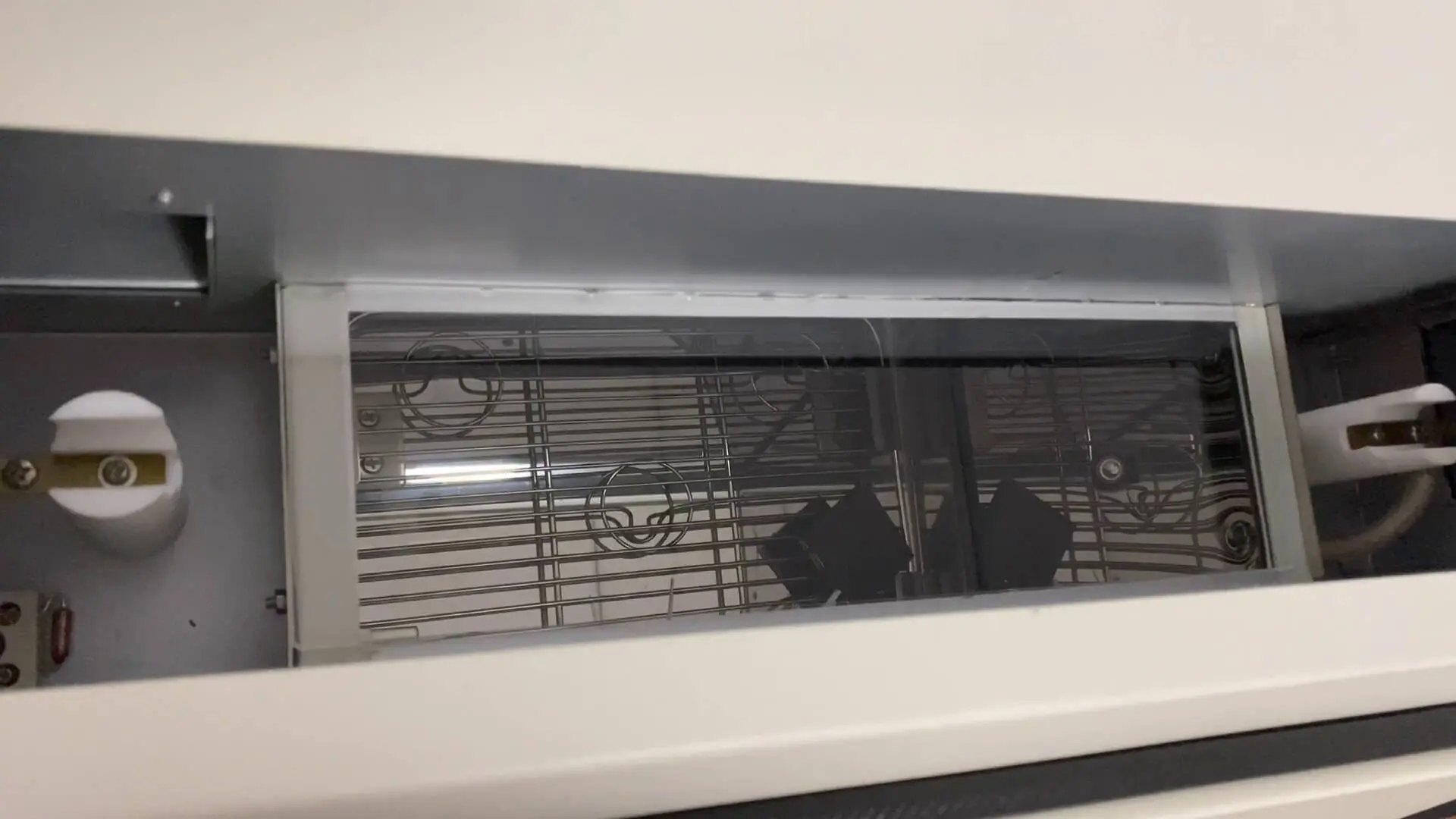

Two rollers have a set of cleaning water tank in the lower part, easy to take out. |

|

|

Transmission |

The transmission motor is 0.4KW gear motor, variable speed regulation, the highest speed of 5 metres/minute. |

|

|

Machine appearance |

Desktop |

|

|

Safety |

There is a small anti-pinch roller between two rollers and an emergency stop switch. |

|

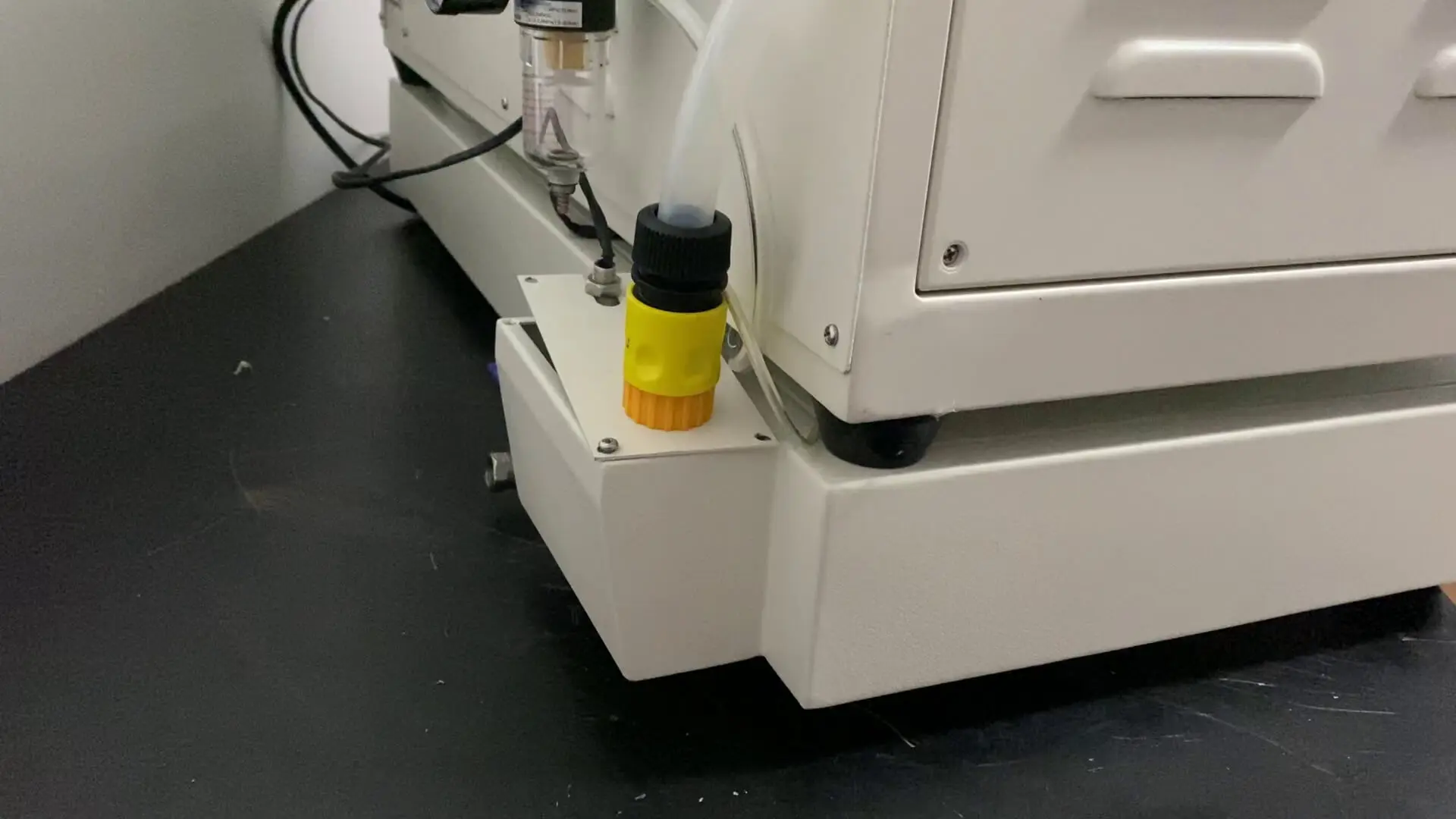

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home