- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Textile Machinery Heat Deformation Vicat Softening Point Tester HP09

Overview

Heat distortion Vicat, softening point temperature tester using PLC programmable controller for temperature regulation using computer display operation. The product is simple to operate, easy to use, stable performance, high precision, and in the test process can be real-time monitoring of the test temperature and deformation; the end of the test system automatically stops heating, and can print the test report and test curve. This series of models is a necessary instrument for the self-inspection of various quality inspection units, colleges and universities and enterprises.

Application

Standards

GB/T1633 Determination of Vicat Softening Temperature (VST) of Thermoplastics

GB/T1634 "Determination of Load Deflection Temperature of Plastics Part 1: General Test Methods"

GB/T8802 "Determination of Softening Temperature of Plastic Pipe Fittings"

IS075-2013 Determination of load deflection temperature of plastics

ASTM D 648 《Test Method for Heat Distortion Temperature of Plastics》

ASTM D 1525 《Test Method for Vicat Softening Temperature of Plastics》

Key Parameters

|

Model |

Technical parameters: |

|

Temperature control range |

Ambient temperature -300°C |

|

Temperature increase |

(120±10)℃/h (12±1)℃/6min (50±5)℃/h (5±0.5)℃/6min |

|

Temperature Error |

0.1℃ |

|

Maximum Deformation Error |

±0.001mm |

|

Measuring range of deformation |

0—10mm |

|

Number of specimen holders |

3 |

|

Load bars and pallet mass |

68g |

|

Test span range |

Depending on the standard 64 or 100 mm |

|

Fuel tank volume |

Around 20L |

|

Heating medium |

Methyl silicone oil or transformer oil (optional) |

|

Cooling method |

Above 150 naturally cooled, below 150 water cooled or naturally cooled |

|

Heating power |

3kw |

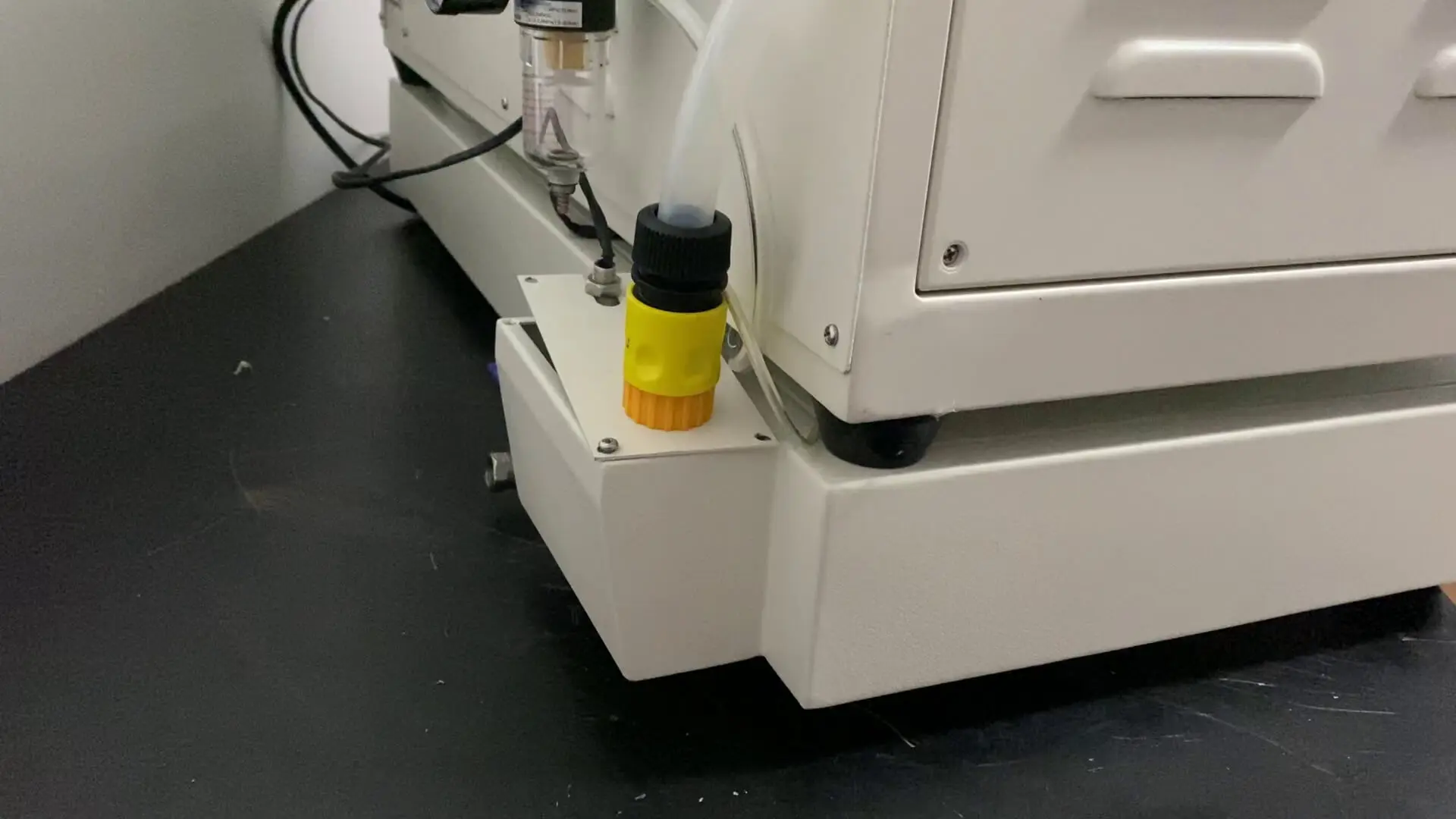

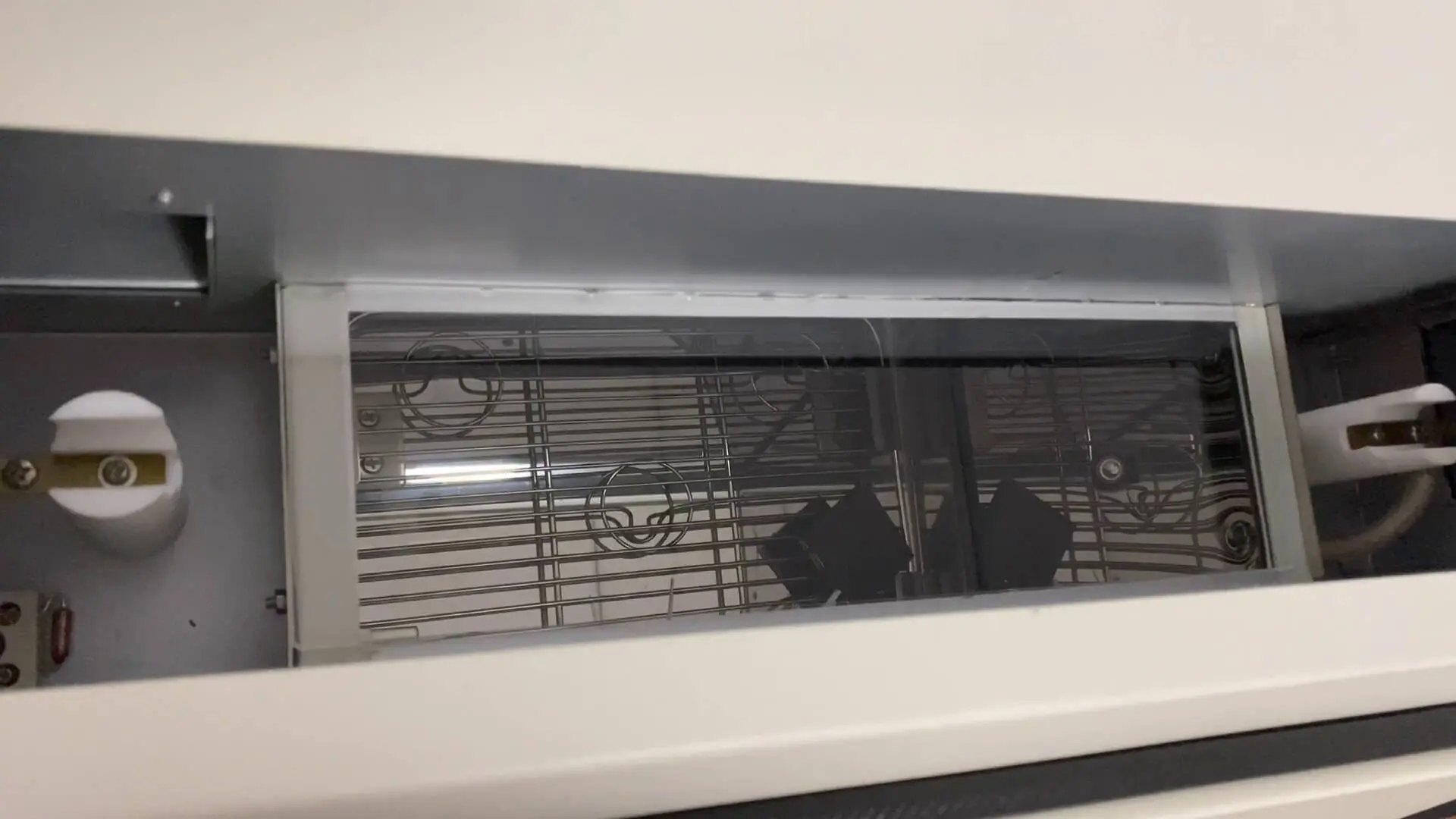

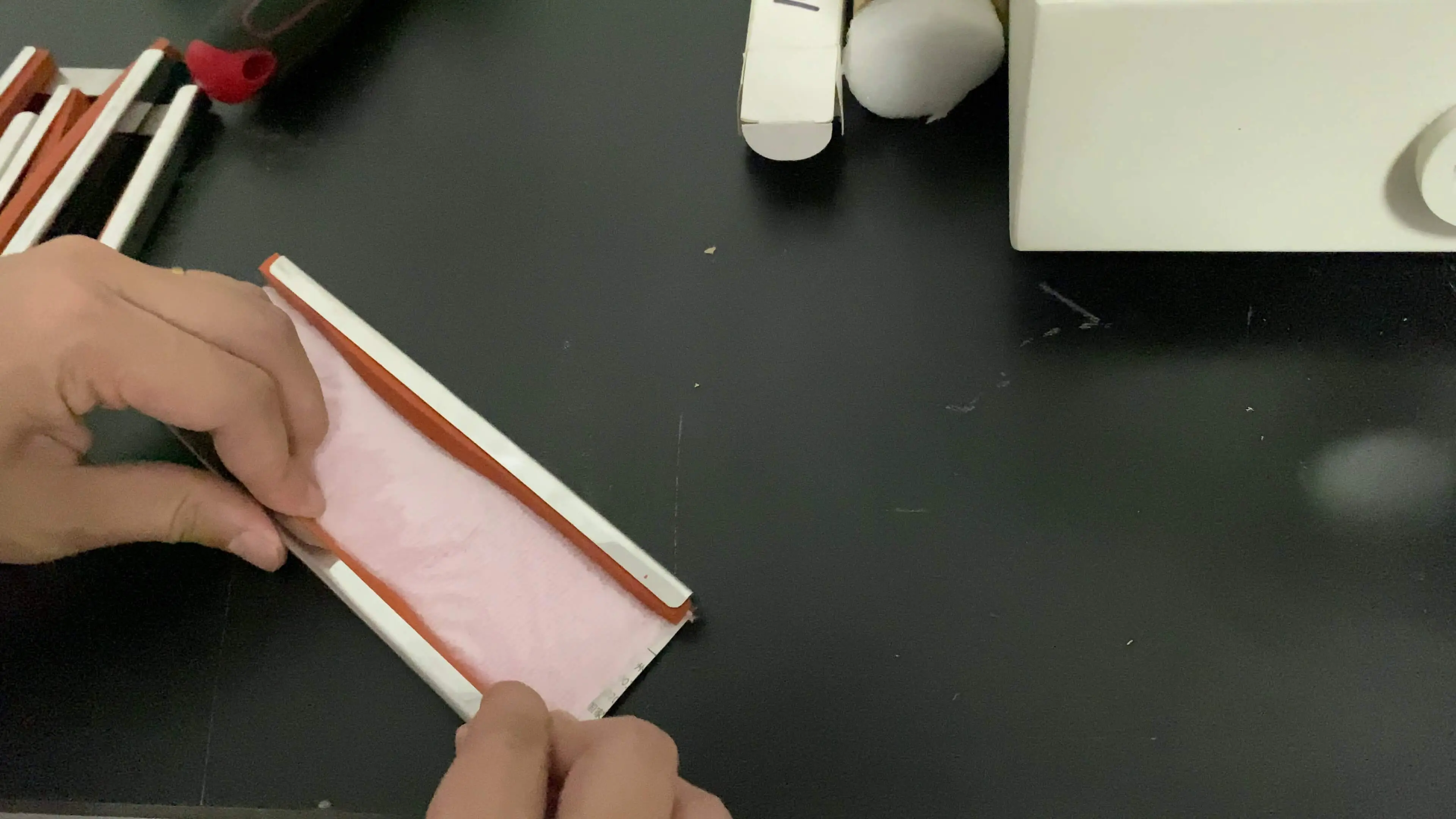

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home