- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

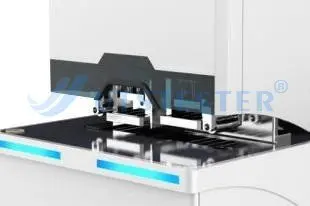

Textile Inspection Equipment Manufacturers Fabric Touch Tester M121

Overview

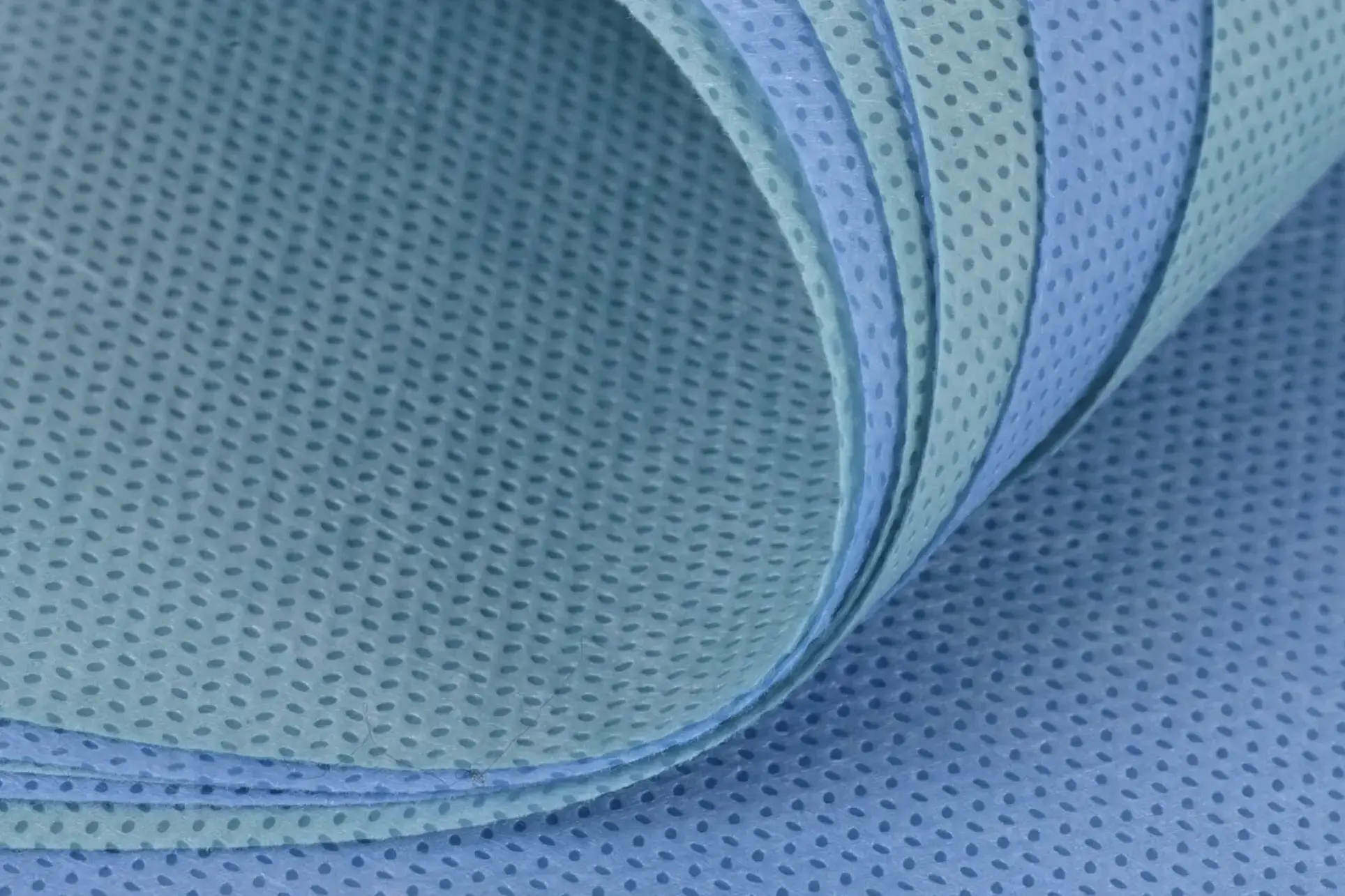

The fabric feel style is not only one of the most important indicators of textile comfort, but also an important factor in the sale of textiles. Therefore, textile feel style measuring instruments have been a research direction of close attention in textile science and technology, and it has become an urgent need to correctly, effectively and objectively evaluate the fabric feel style. The system is based on the concept of single-computer, single-measurement, multi-indicator testing. By simulating the manual touch of the fabric pulling, pressing, pinching, kneading and rubbing, the system can test the thickness, bending, compression, friction and stretching properties of the fabric, and obtain five quantitative indicators of thickness, softness, stiffness, smoothness and tightness to objectively evaluate the comprehensive handfeel style of the fabric. Suitable for general fibre sheet products: clothing fabrics, home textiles, non-wovens, yarns, automotive upholstery, leather, paper, etc.

Application

Standards

Standards

Key Parameters

|

Model |

M121 |

|

Sample size |

50*500mm |

|

Maximum thickness |

4mm |

|

Testing range |

0-80mm |

|

Power supply |

AC 220V 50Hz |

|

Dimension(L×W×H) |

500mm×480mm×780mm |

|

Weight |

100kg |

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home