- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Packaging Carton Compressive Strength Paper Tube Compressive Strength Tester Box Compression Test Machine A020

Overview

Application

Standards

Key Parameters

Pressure measurement range 0-10000N

Resolution 1N

Accuracy of pressure measurement:

l The error of the indicated value is ±2%

l Indicated value variability ≤2%

l Return to zero error ±0.2%FS

Deformation measurement accuracy ±1mm

Stacking test preset load

Relative volatility ±4%

Pressure speed adjustment range 5mm/min ~ 90mm/min

The relative error of pressure speed was (5 ~ 90) mm/min, ±3%

Standard pressurization speed 12mm/min

Stacking test tracking pressure speed 5mm/min

The test speed of paper tube was (55±5) mm/min

The working stroke of upper pressure plate is 400mm

Test range 350mm*350mm*400mm

The parallelism between the upper and lower plates is ≤1mm

Communication output can be configured with Rs232 (software purchased separately)

Test machine dimensions (l×b×h, mm) 720*500*900mm

The total weight of the testing machine is about 150KG

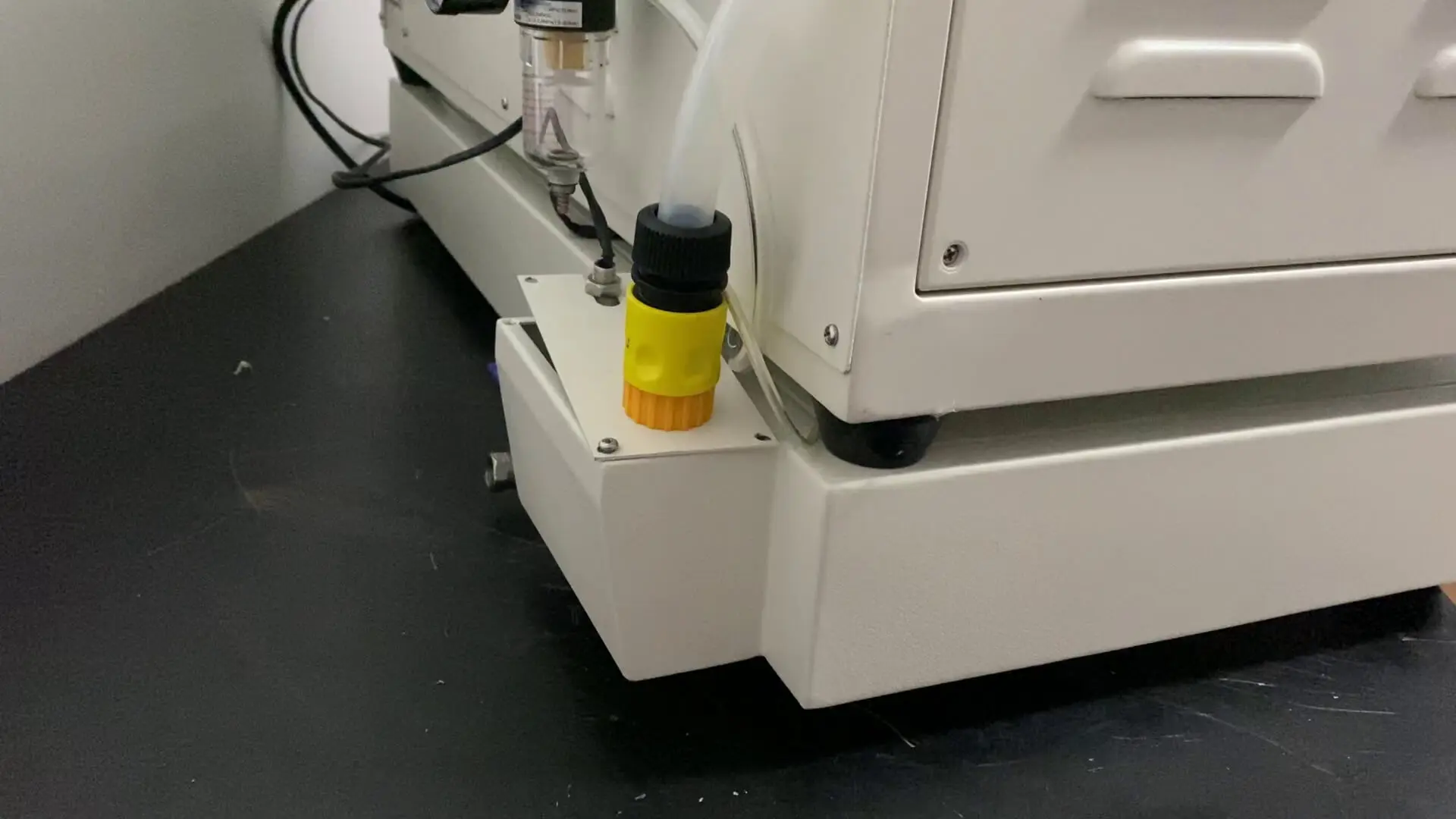

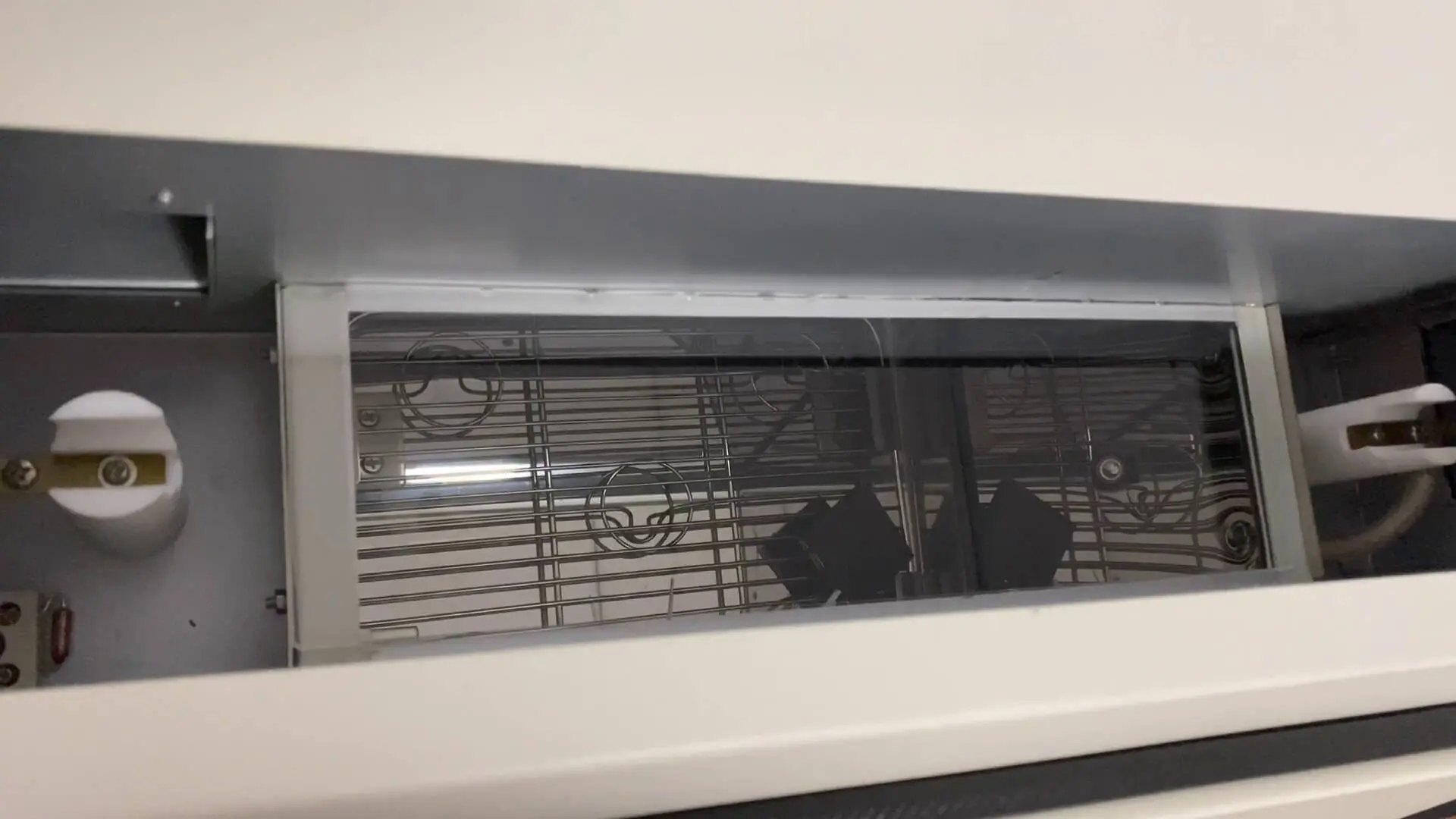

Product Details

Production Processes

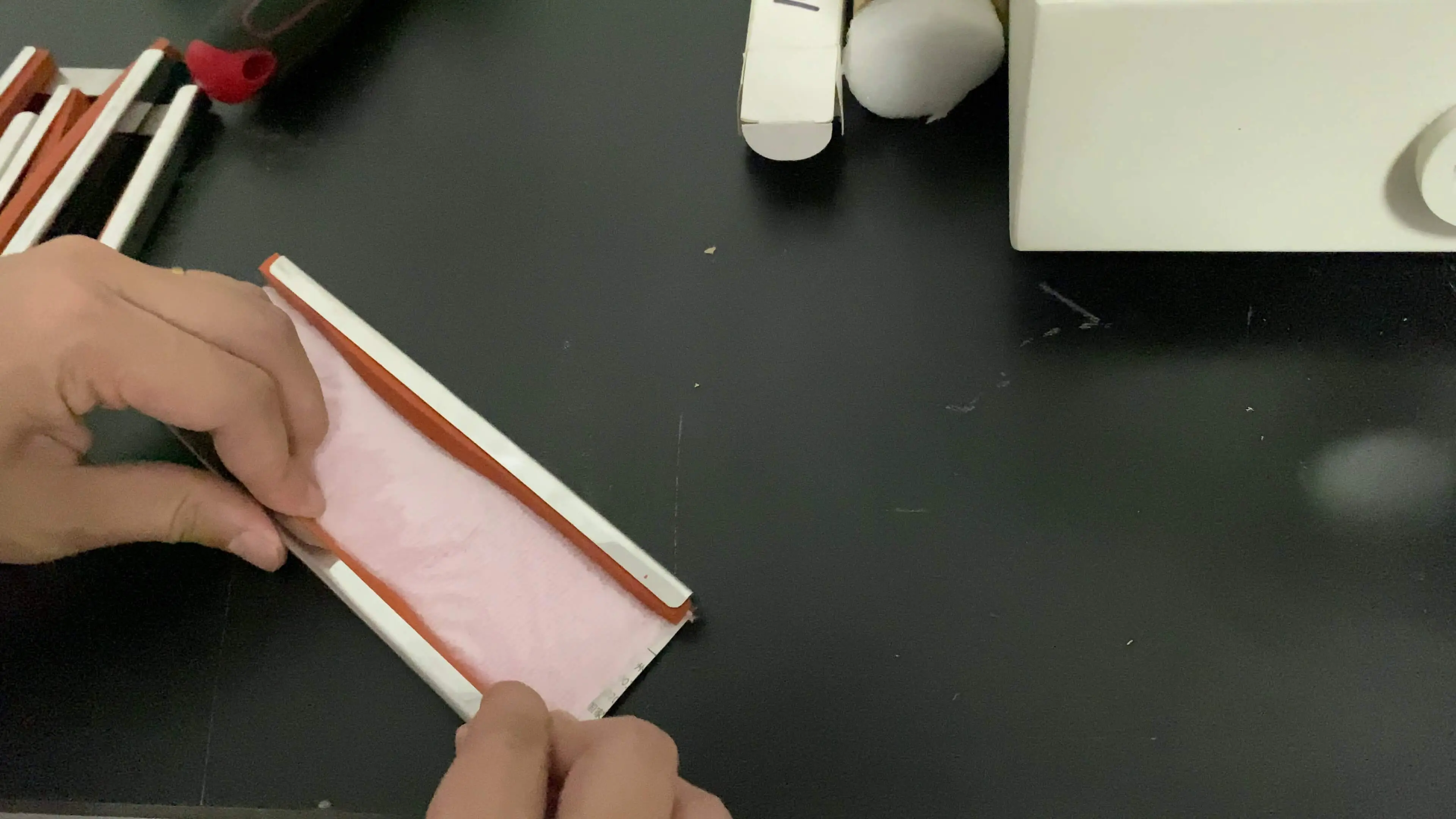

Scenarios of Use

Operation

Transportation

Home

Home