- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Laundry Washing Colorfastness Tester Launderometer for Textile Color Tester D007B

Overview

D007 Laundry / Washing Colorfastness Tester is to determine the washing and dry colorfastness resistance property for dyed textile or dyed yarn after washing.

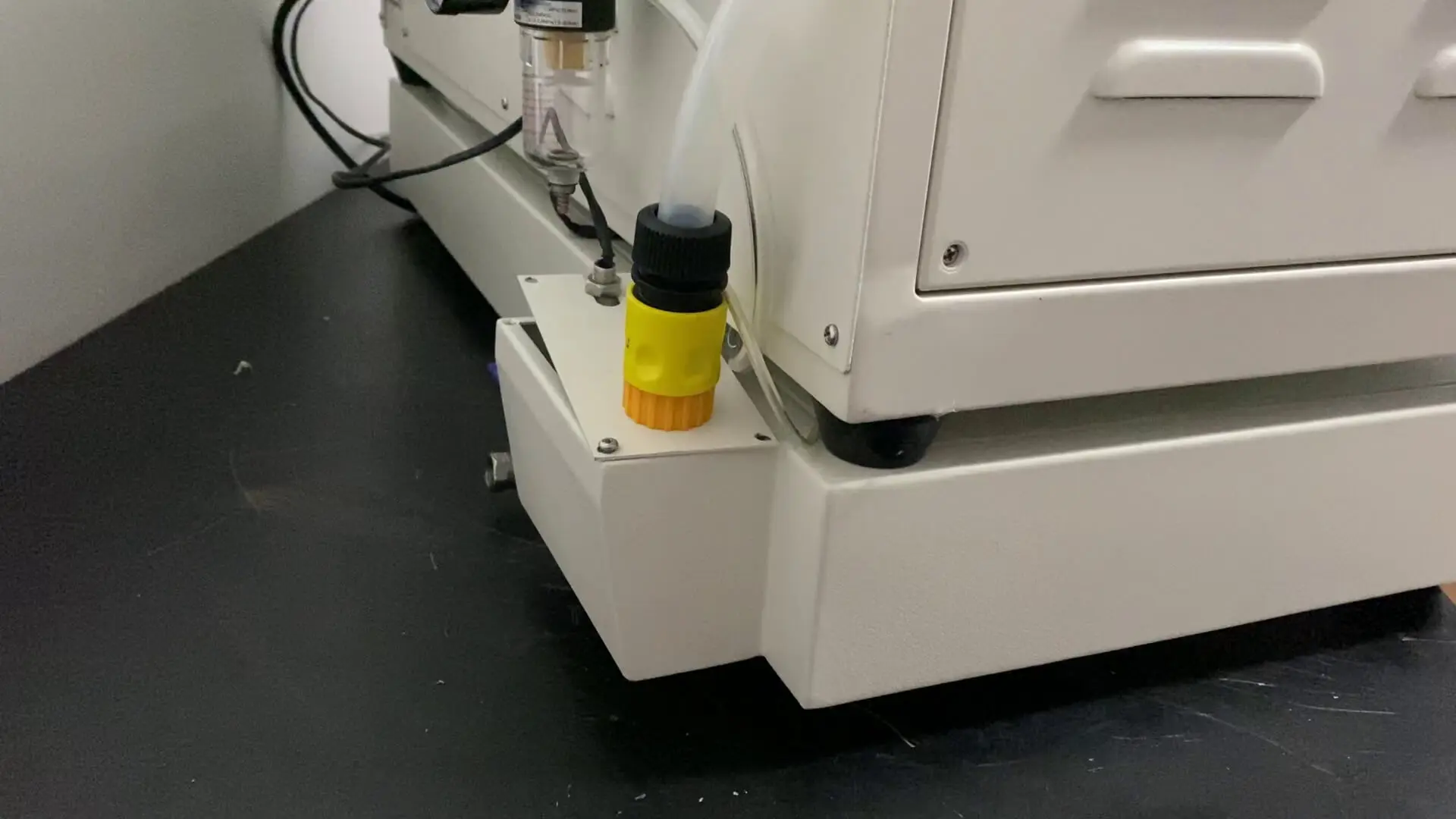

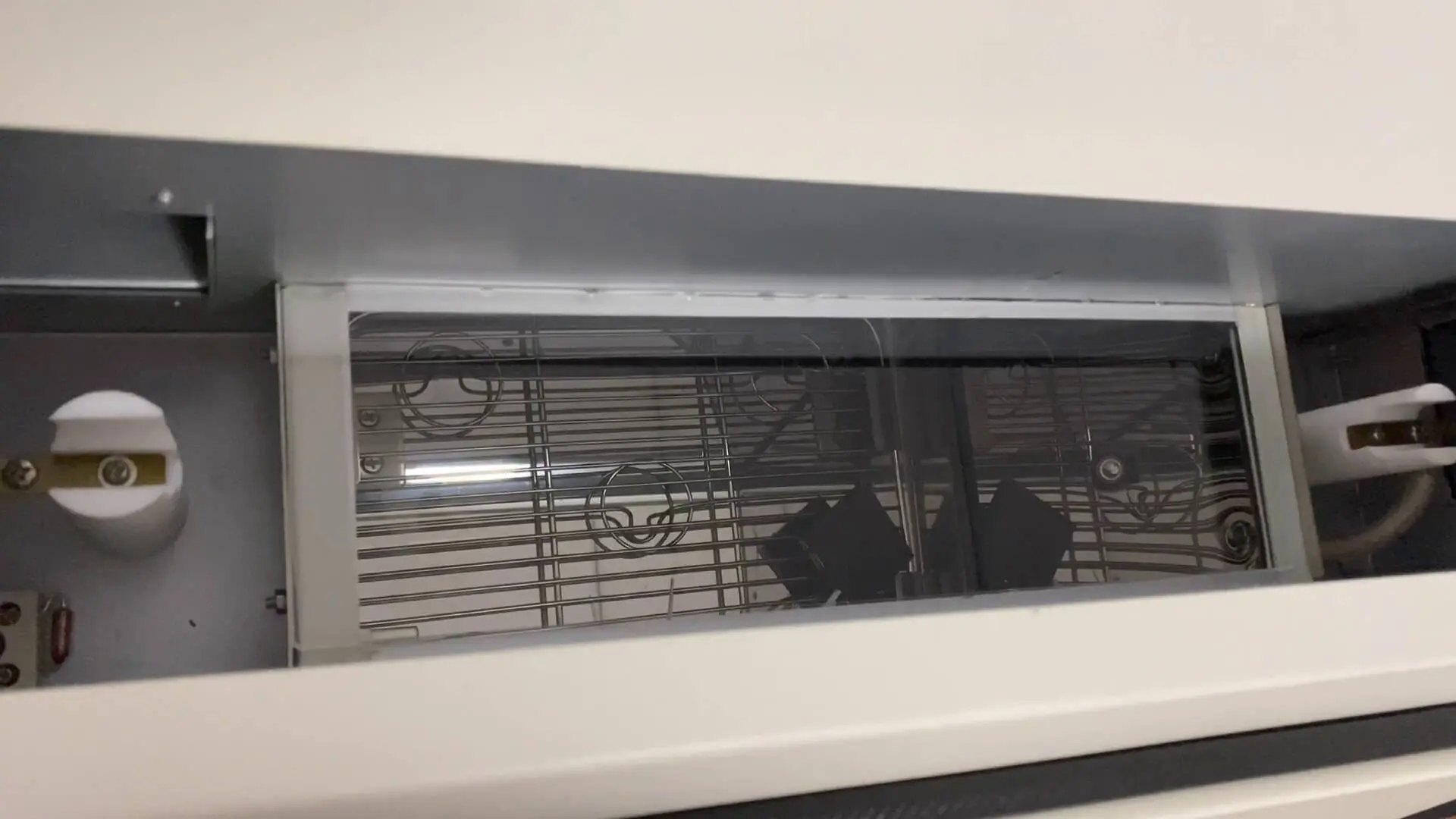

The all stainless steel construction stands up to the hard environment of wet labs, which is reliable and durable. Equipped with an easy opening door and quick-lock retention bars for the containers to ease loading and unloading.

Application

Standards

ISO105-C01, C02, C03, C04, C05, C06, C08, C09, C10, D01, E03, E12

AATCC 3, 61, 62, 86, 132, 151, 162, 190; GB/T 5711, GB/T3921-1 ~ 5, GB/T 12490 ;

JIS L0860, JIS L0844, JIS L0879; M&S C4A, C5, C37, P3B; BS 1006 NEXT 2,3,5 Key Parameters

|

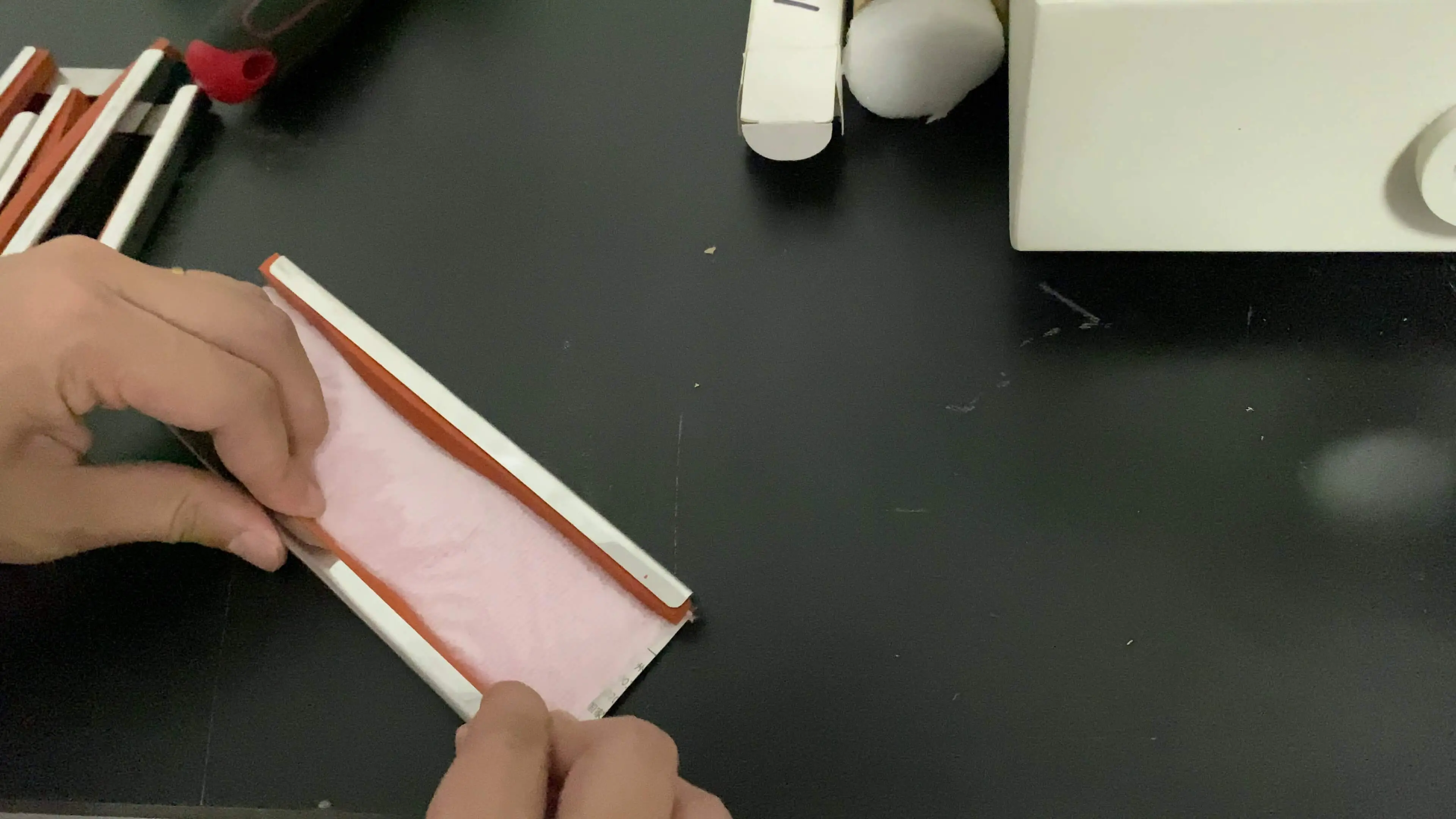

Washing cups |

A(AATCC cup volume): 1200±50ml B(ISO cup volume): 550±50ml |

||||||

|

Washing cups

|

Model No. |

D007E-12B |

D007E-6AB |

D007E-20B |

D007E-10AB |

D007E-24B |

D007E-12AB |

|

Combination |

12B |

6A+6B |

20B |

10A+10B |

24B |

12A+12B |

|

|

Water inflow and drain design |

Automatically |

||||||

|

Display |

Touch screen display |

||||||

|

Rotation speed |

40±2 rpm |

||||||

|

Timing range |

1~999min |

||||||

|

Temperature range |

Room temp. to 99 centigrade degree |

||||||

|

Temperature fluctuation |

<±1 centigrade degree |

||||||

|

Heating methods |

Electrical heating tube |

||||||

|

Power supply |

3∮AC 380V 50/60HZ 5KW |

||||||

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home