- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

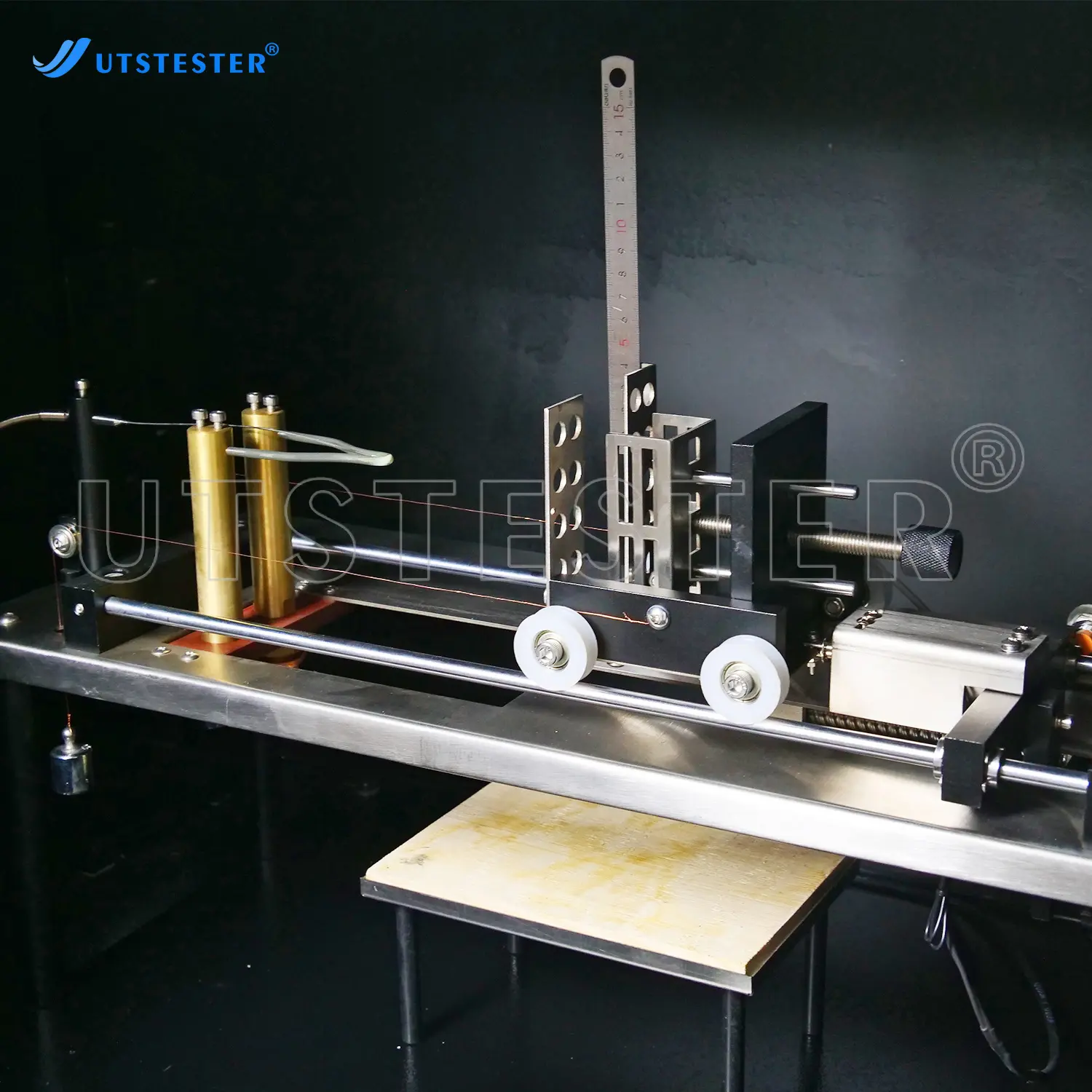

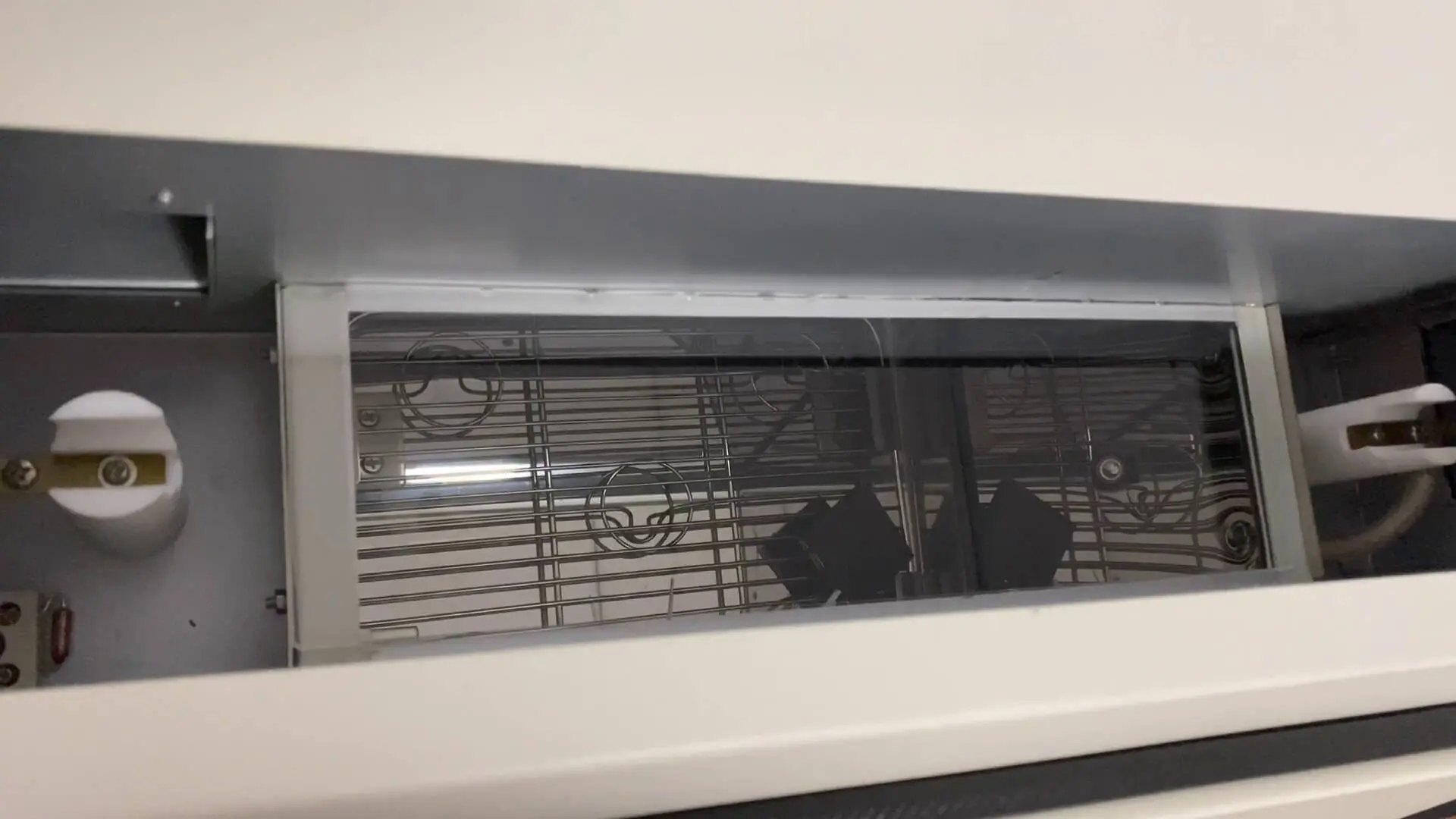

Laboratory Glow Wire Tester High Temperature Flammability Tester TF01B

Overview

This test equipment complies with the requirements of IEC60695 and GB5169 standards; it is used to conduct high temperature flammability tests on plastic material components of electrical equipment and appliances. The product box shell is powder-coated and equipped with a transparent observation window, a seven-inch programmable touch screen controller and USB test report data output. This device has beautiful appearance, easy use and reliable performance.

Application

Standards

IEC60695 and GB5169

Key Parameters

|

ITEM |

COMMENT |

|

Model |

UTS-TF01B |

|

Temperature range |

50℃~1050 ℃ |

|

Temperature deviation |

±2℃ |

|

Glow wire |

Φ4mm Ni/Cr(80/20) (Professional mold forming, high dimensional precision) |

|

Thermal couple |

Φ1.0mm K type(Original imported. Higher serve life) |

|

Sample test pressure |

1.0N±0.1N |

|

Sample moving speed |

10mm /s~25mm /s (Available with forward and backward separate speed) |

|

Applying temperature time |

0~999 degrees (adjustable) |

|

Ignition time range |

0~999.9S |

|

Sustained combustion time range |

0~999.9S |

|

Outlet diameter |

100mm |

|

Power |

AC 220V 50HZ 1 ∮ 2wire 10A |

|

Inner dimension |

112* 60 * 102㎝ (W*D*H) |

|

External dimension |

112 * 65* 140 ㎝ (W*D*H) |

|

Weight |

150kg |

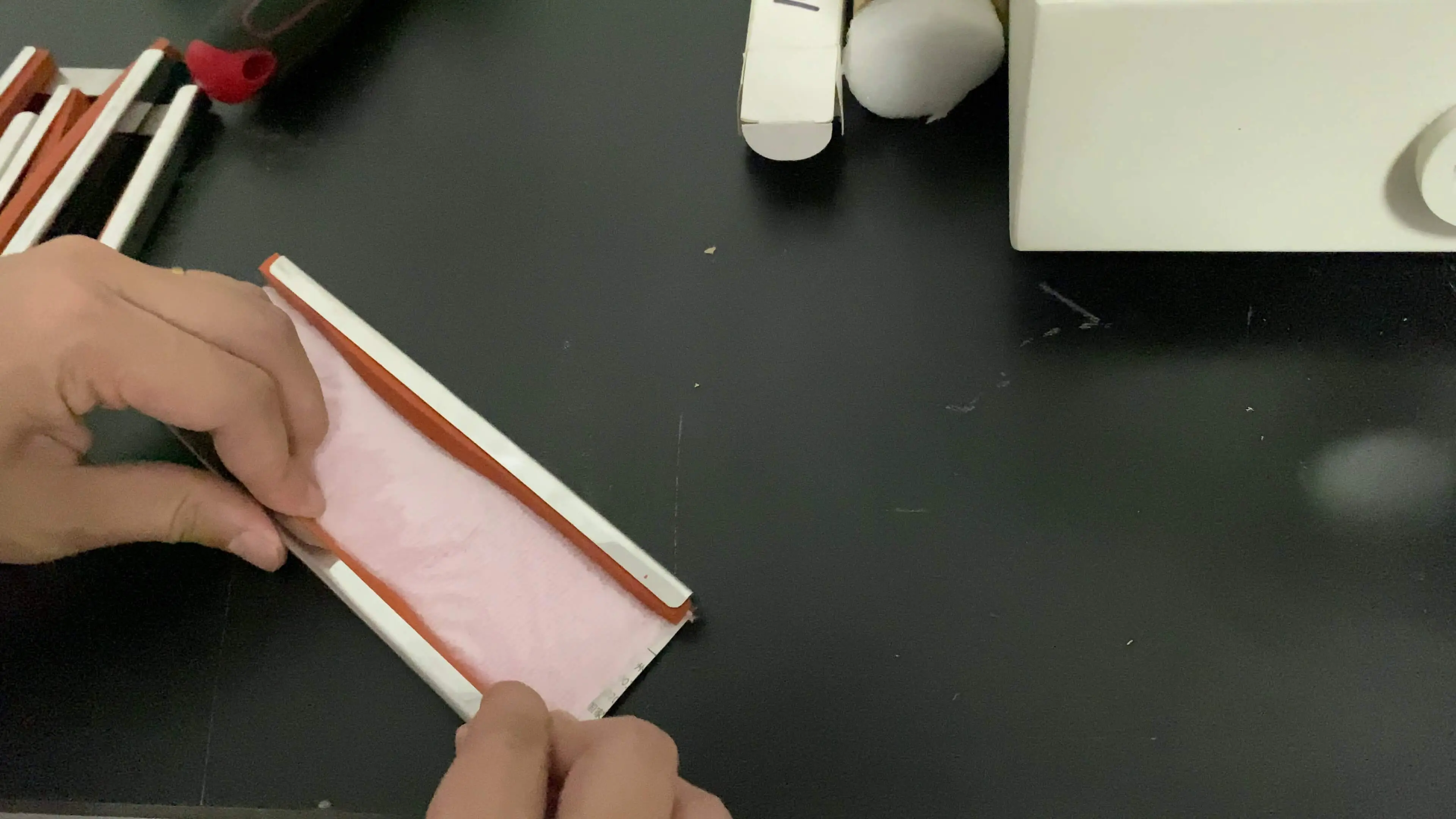

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home