- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Laboratory Continuous HT Steamer Stenter Fabric Color Fastness Tester D018C

Overview

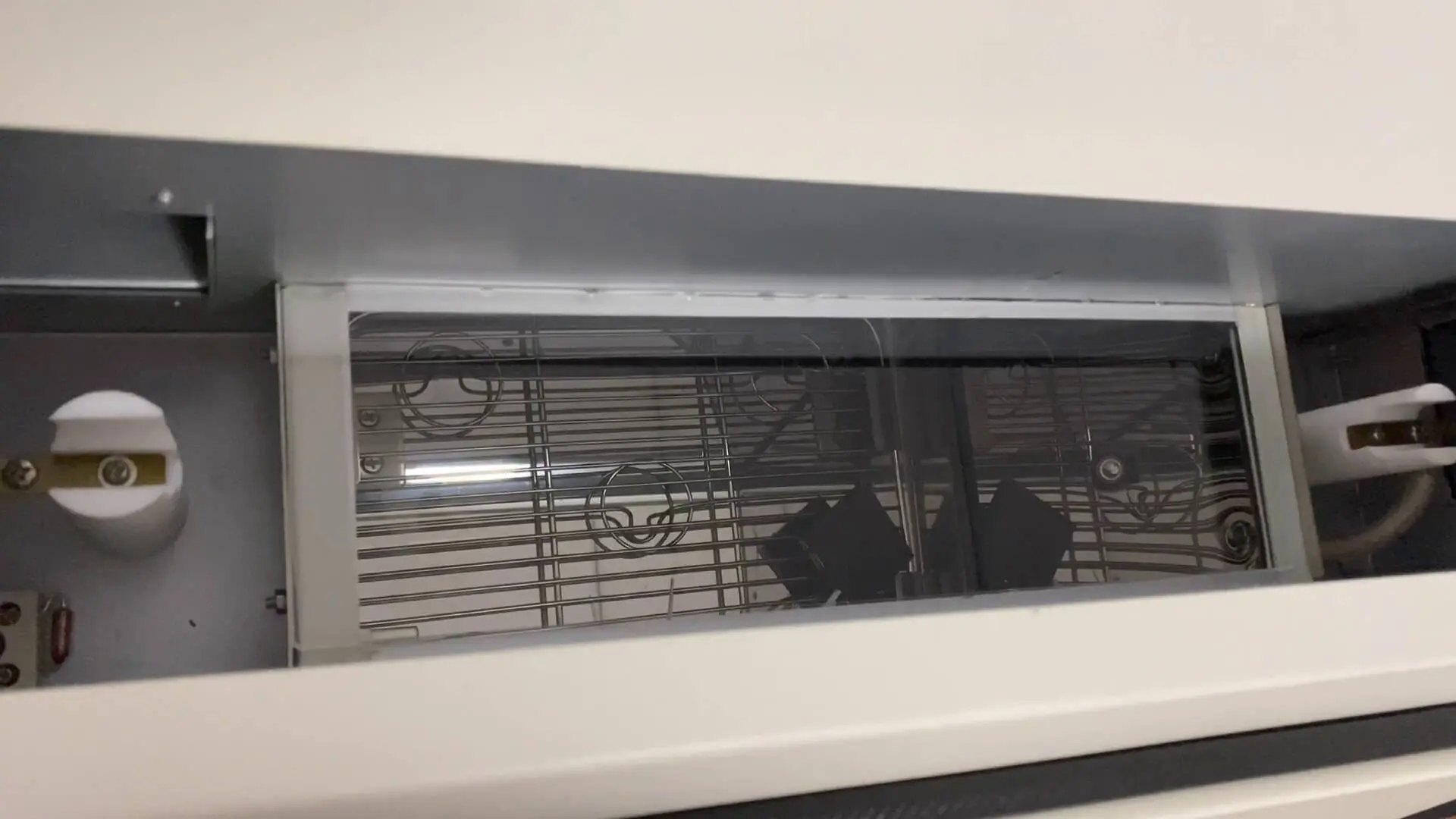

Used to simulate dyehouse’s dyeing and finishing process in laboratory. Conduct resin hot melting dyeing and baking test, and combine with verification dyestuff and accessory ingredient to constitute recipe and technology condition. Test hand feeling for fabrics, dyestuff color change degree, color fastness, etc, related important quality, so as to obtain correct finished product organization model.

Due to the input and output materials of test samples are via continuous pin-frame chain transmission, coordinate the adjustable temperature, the test sample(fabric) do not need to be ironed and dyed within traditional oven. Use this unit to provide fast and flat dry test template, so as to enhance color test efficiency.

Application

Key Parameters

|

Model |

D018C |

|

Needle Plate Chain |

100 x 350mm |

|

Needle Plate Shelf |

125 x 250mm |

|

Heating Method |

electrical heating, 12kw |

|

Time Control |

Detained time inside oven can be adjusted: 20s - 6min |

|

Fan Motor |

1/6 HP motor |

|

Drive Motor |

1HP motor |

|

Power Supply |

3∮AC 380V 50/60HZ 18kw |

|

Dimension |

241 x 94 x 139 cm |

|

Weight |

650 kg |

|

Standard accessories |

Power Line |

|

Optional accessories |

Other standard printing frame |

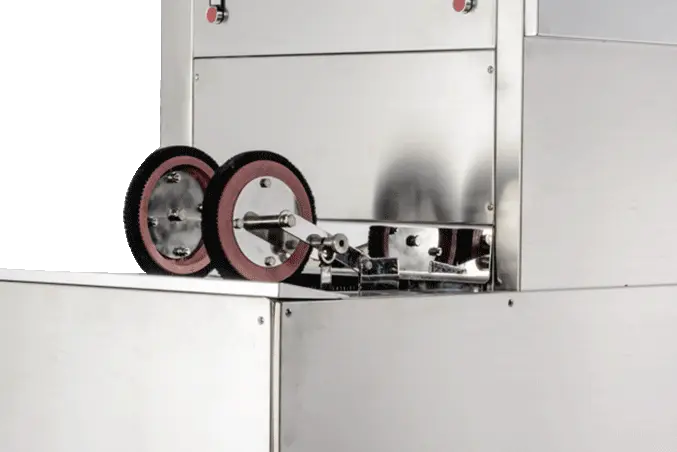

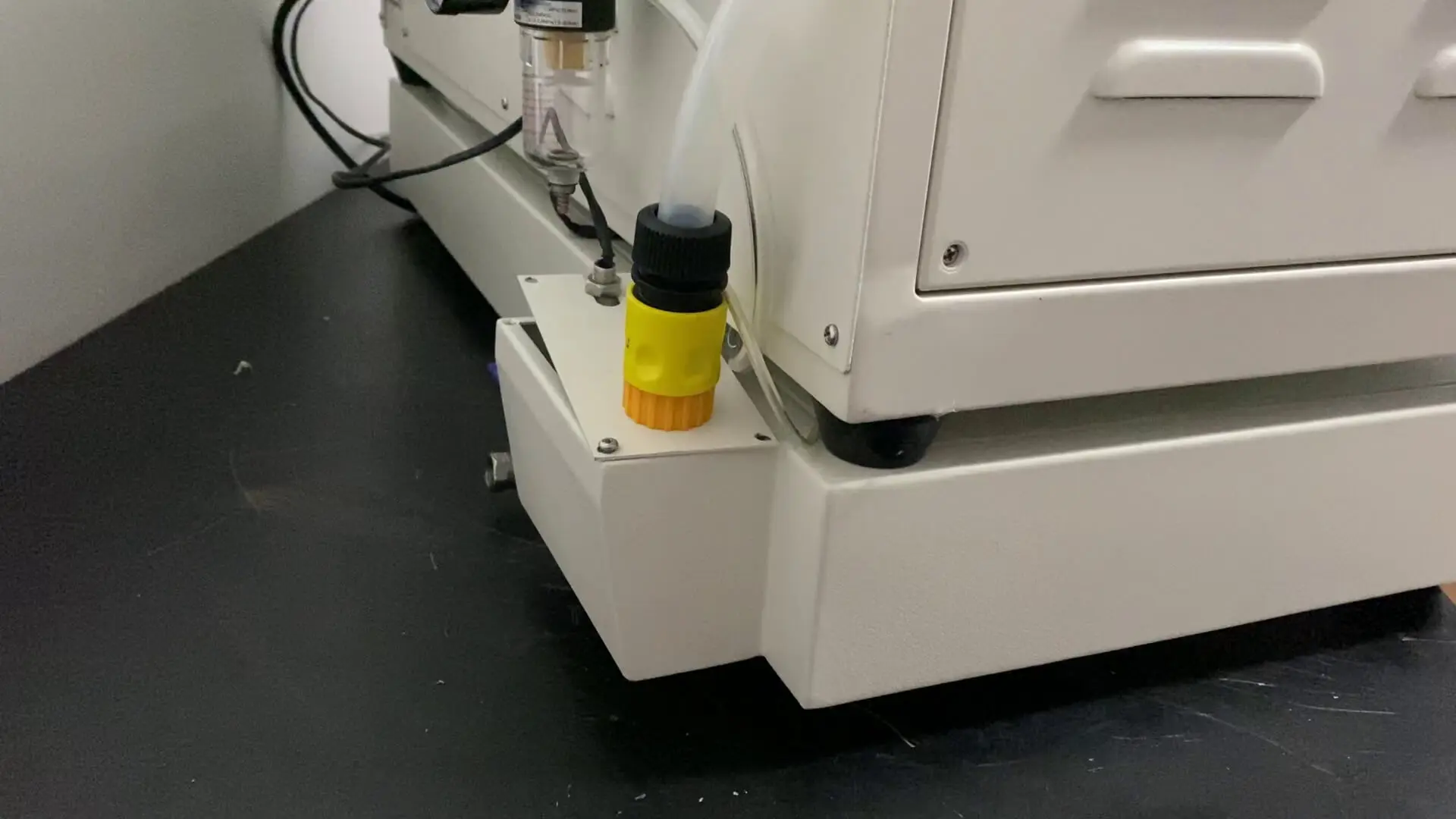

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home