- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Lab Bobbin Yarn Dyeing Machine Deal with The Loose Cotton Wool or Chemical Fiber D028

Overview

Application

Standards

Standards

Key Parameters

|

Model |

D028 |

|

Minimum working capacity |

1kg(barrel yarn), maximum working capacity: 3kg (barrel yarn) |

|

Working pressure |

0-0.40MPa |

|

Maximum design pressure |

0.50MPa |

|

Operating temperature |

room temperature -135℃ |

|

Design maximum temperature |

140℃ |

|

Working medium |

dye |

|

Bath ratio range |

1:6 ~ 1:15 |

|

Power supply |

three-phase 380V, 50HZ |

|

Main pump motor power |

Main pump motor power: 2.2KW |

|

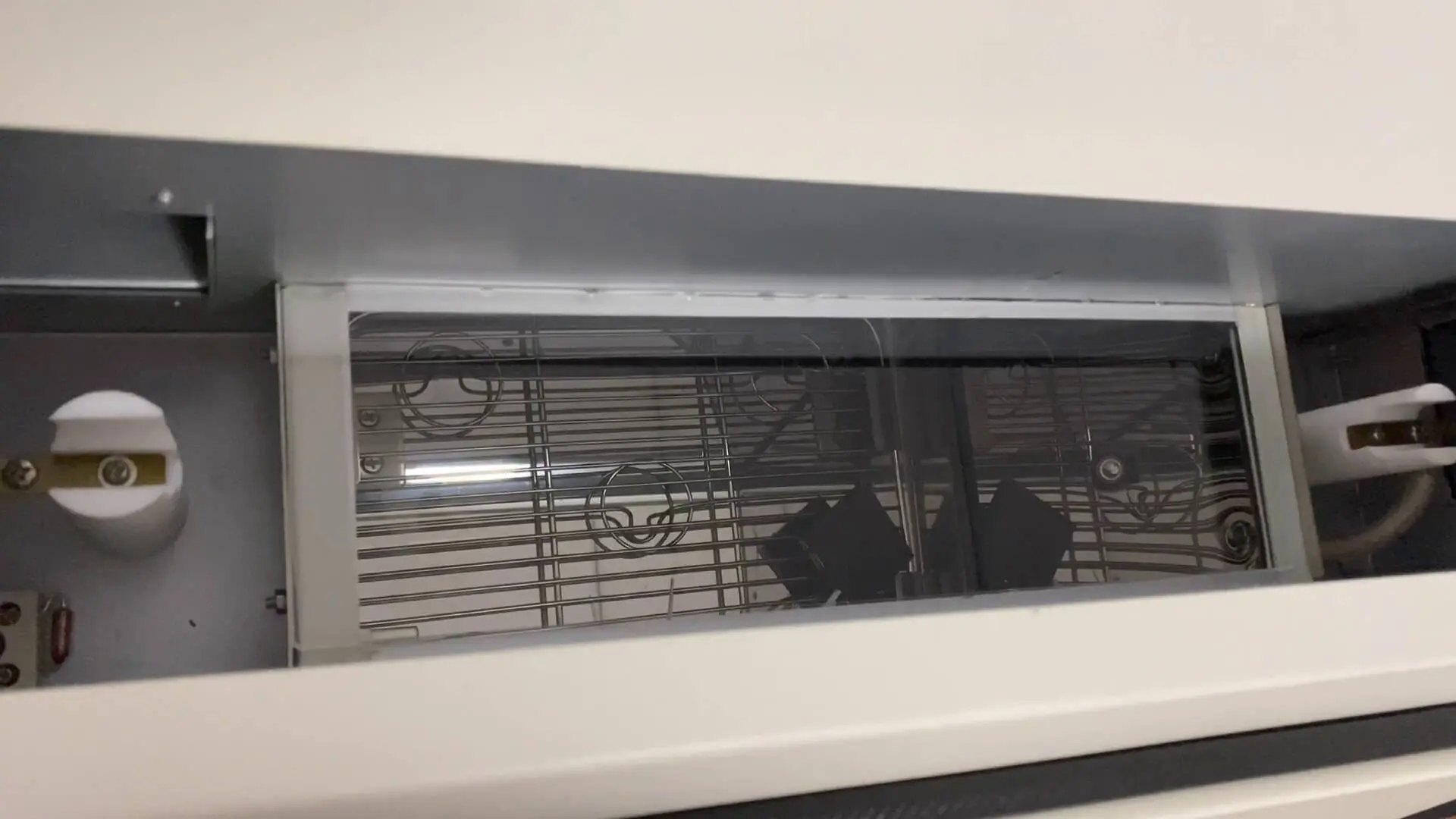

Vertical cylinder |

Cylinder body stainless steel 304, inner diameter 200mm, height 800mm |

|

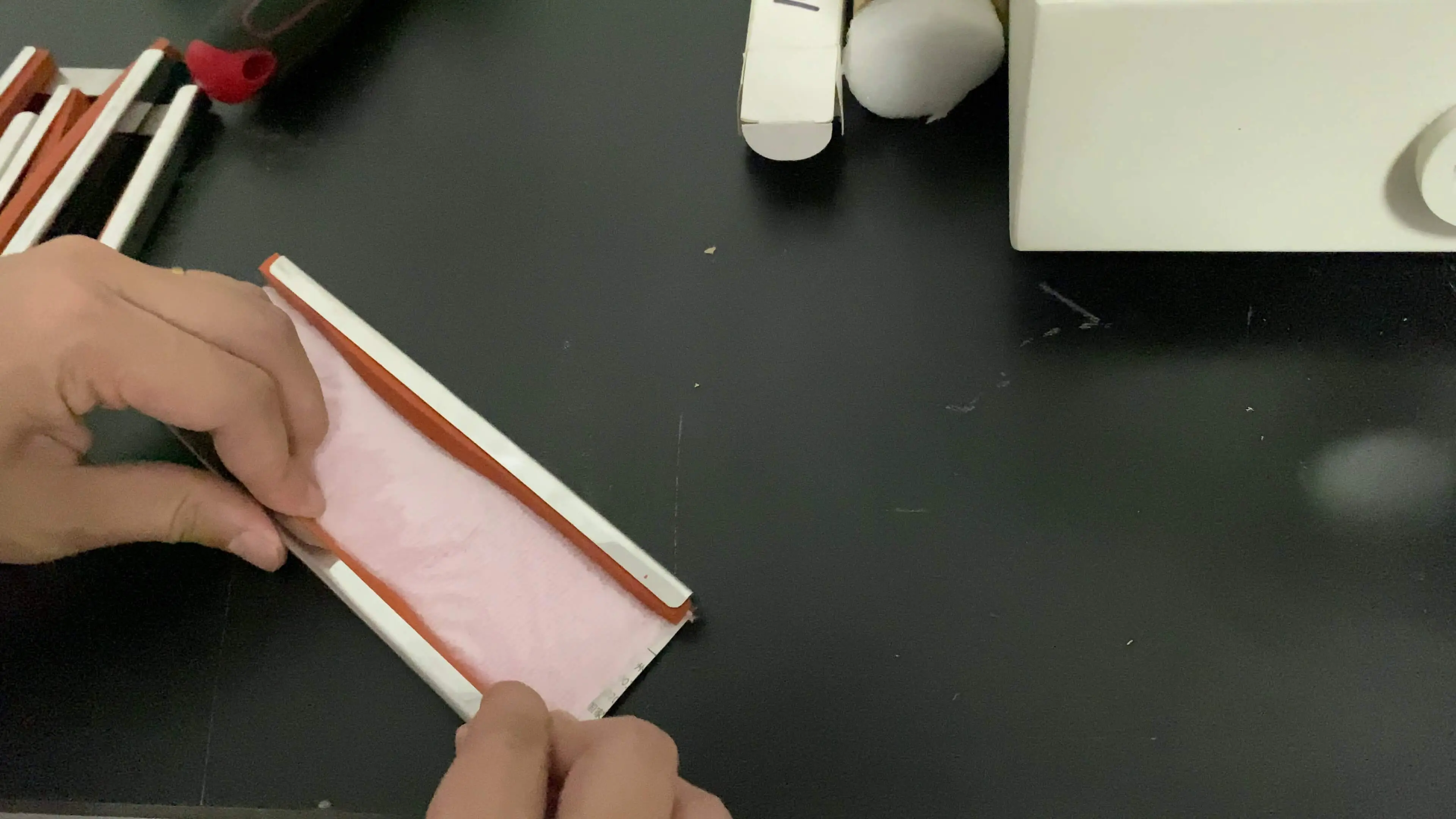

Core rod |

Round mandrel 45×1.5 with pressure lock head, lower disc |

|

Lid seal |

Silicone rubber sealing belt, internal pressure self-sealing |

|

Open cover system |

Manual turn to open the cover |

|

Safety device |

Lock ring safety mechanism, master cylinder with safety valve, pressure gauge protection device |

|

Heating method |

Electric heating |

|

Reversing device |

There is a special reversing device, and the computer controls the automatic flow reversing |

|

PLC control |

Large screen touch screen PLC control, flexible and convenient operating system, digital setting of process parameters, high degree of automation, can be personalized programming according to customer needs. |

|

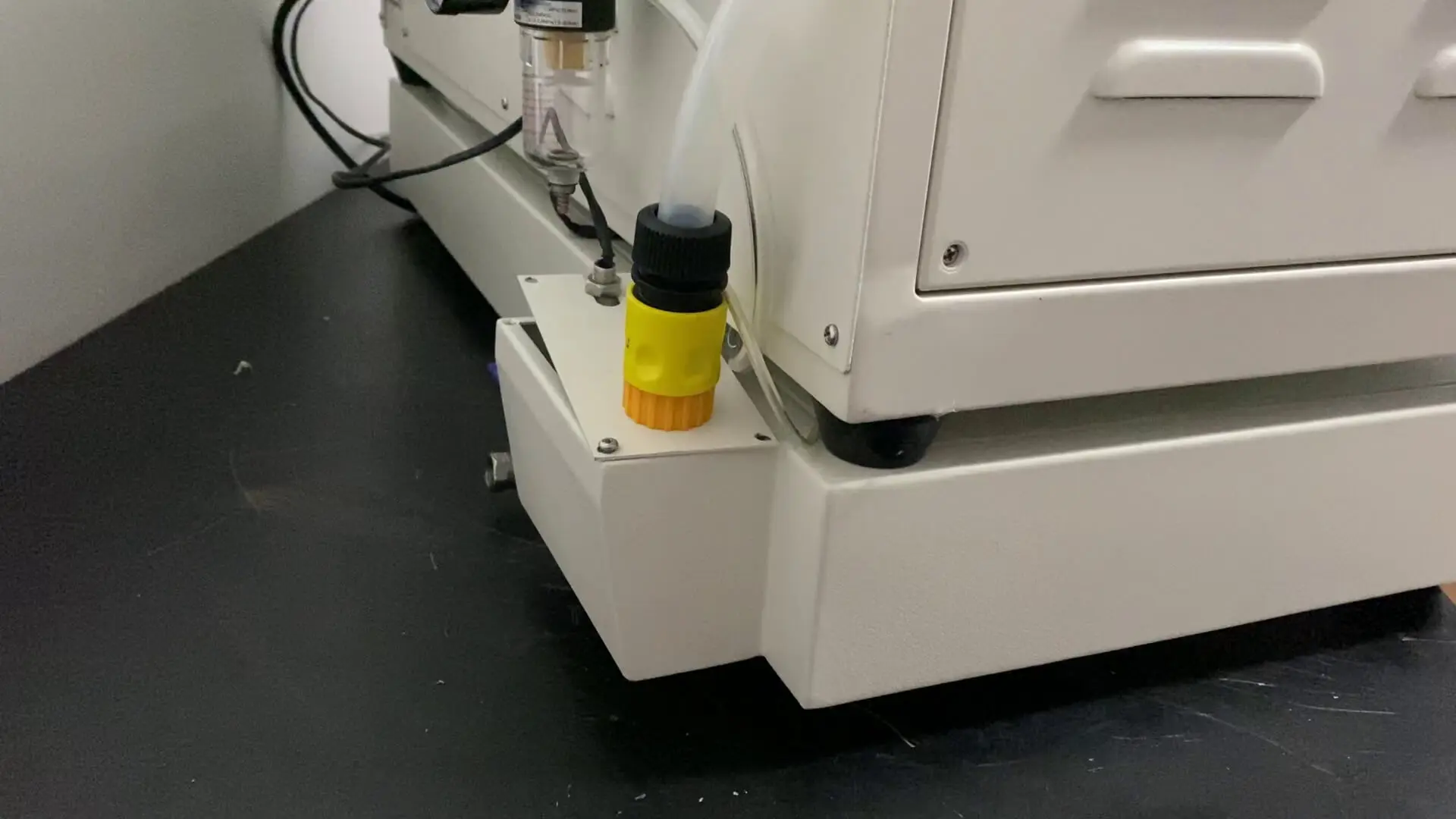

Chemical feed system |

The chemical barrel is equipped with the function of reflux circulation chemical material and automatic proportional feeding and timing feeding |

|

Main pump |

Centrifugal pump |

|

Intake and drainage |

Automatic water metering, single entry, single row, stainless steel pneumatic valve control |

|

Valve door |

Water inlet, sewage: DN20 pneumatic ball valve |

|

Liquid level gauge |

The master cylinder is equipped with a magnetic replica liquid level gauge, and the chemical barrel is equipped with a liquid level detection system |

|

Host processing |

The surface is sprayed with stainless steel high temperature metal paint, and the interior is acid-washed and passivated |

|

Random gift |

Mechanical seal static ring and pot seal each set |

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home