- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

Infrared Laboratory High Temperature Sample Dyeing and Washing Fastness Testing Machine D017A

Overview

Application

Standards

Key Parameters

|

Model |

D017A |

D017B |

|

|

Staining cup quantity |

12 |

24 |

|

|

Staining cup volume |

150ml, 200ml, 300ml, 420ml, 500ml, optional |

||

|

Material |

Machine shell adopts stainless steel powder spraying process. Internal adopts SUS 304 stainless steel material. |

||

|

Heat method |

Infrared heat tube |

||

|

Temperature range |

RT - 140 ℃ |

||

|

Temperature control accuracy |

±0.1 ℃ |

||

|

Heating/Cooling rate |

|||

|

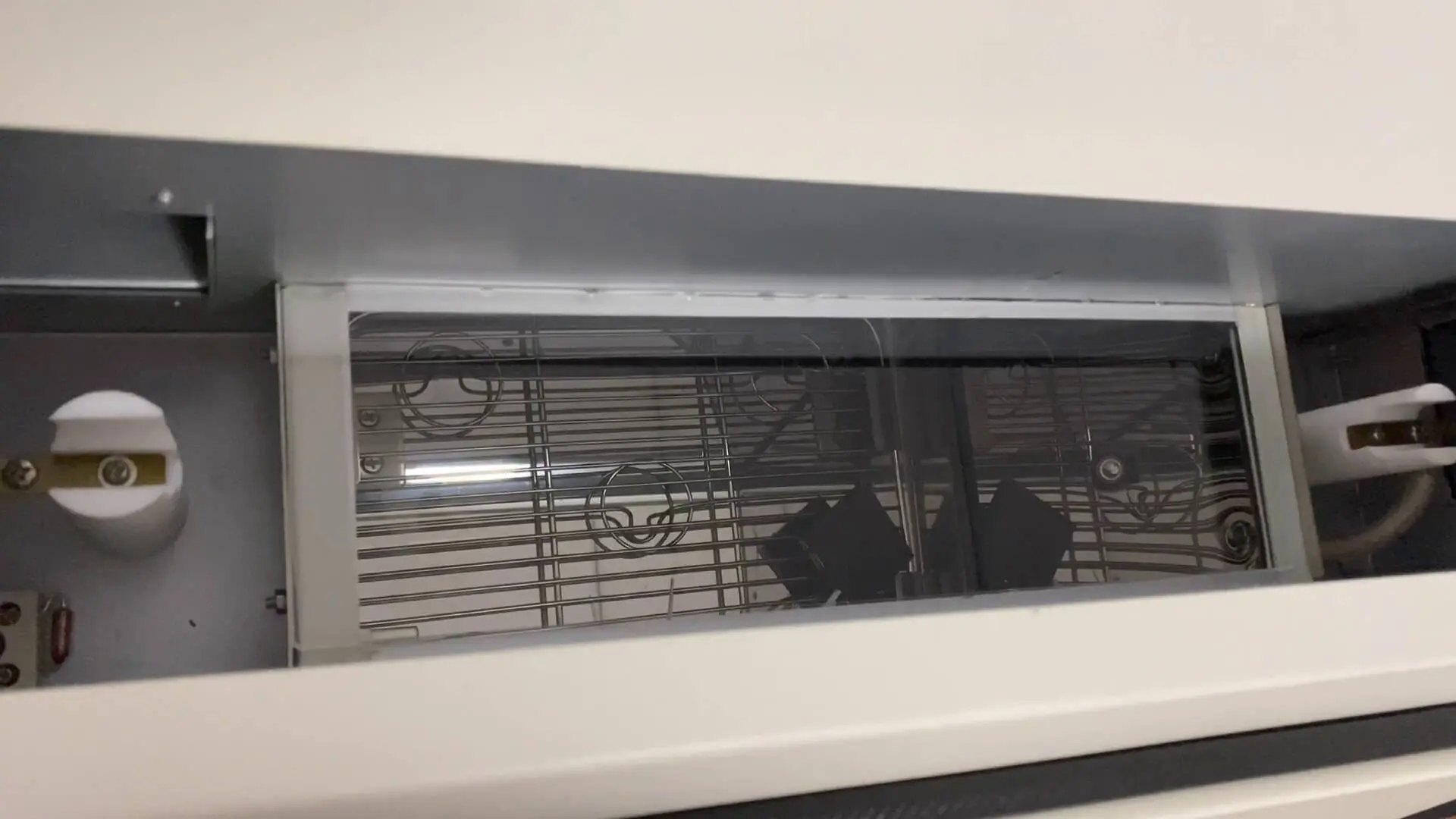

Cooling method |

Air-cooled |

||

|

Rotation speed |

0 - 60 rpm |

||

|

Liquor ratio |

1:5 -1:30 |

||

|

Infrared heat tube |

No direct heat dye cups, Machine heat conduction oil to avoid temperature difference between cups. |

||

|

eletronic component |

Siemens, Schneider |

||

|

Power consumption |

6KW |

6.5KW |

|

|

Heating power of single-side nano-coated infrared lamp tube |

6 units, 1KW/unit, 2pcs connection in series, 4.8KW |

6 units, 1.2KW/unit, 2pcs connection in series, 5.4KW |

|

|

Power supply |

AC 380V 50/60HZ |

||

|

Dimensions( L x W x H) |

700×750×750mm |

800×750×750mm |

|

|

Weight |

120kg |

136kg |

|

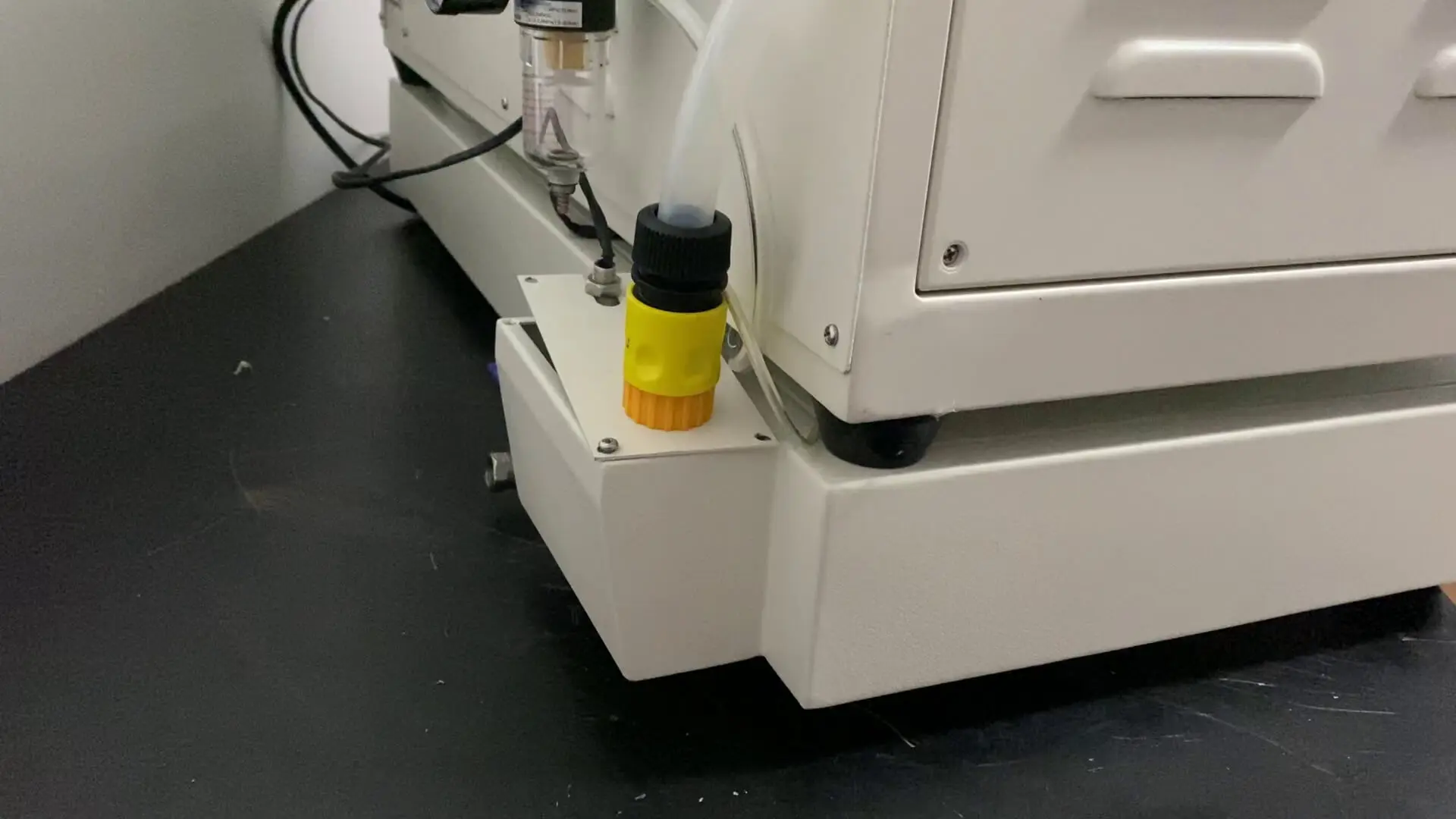

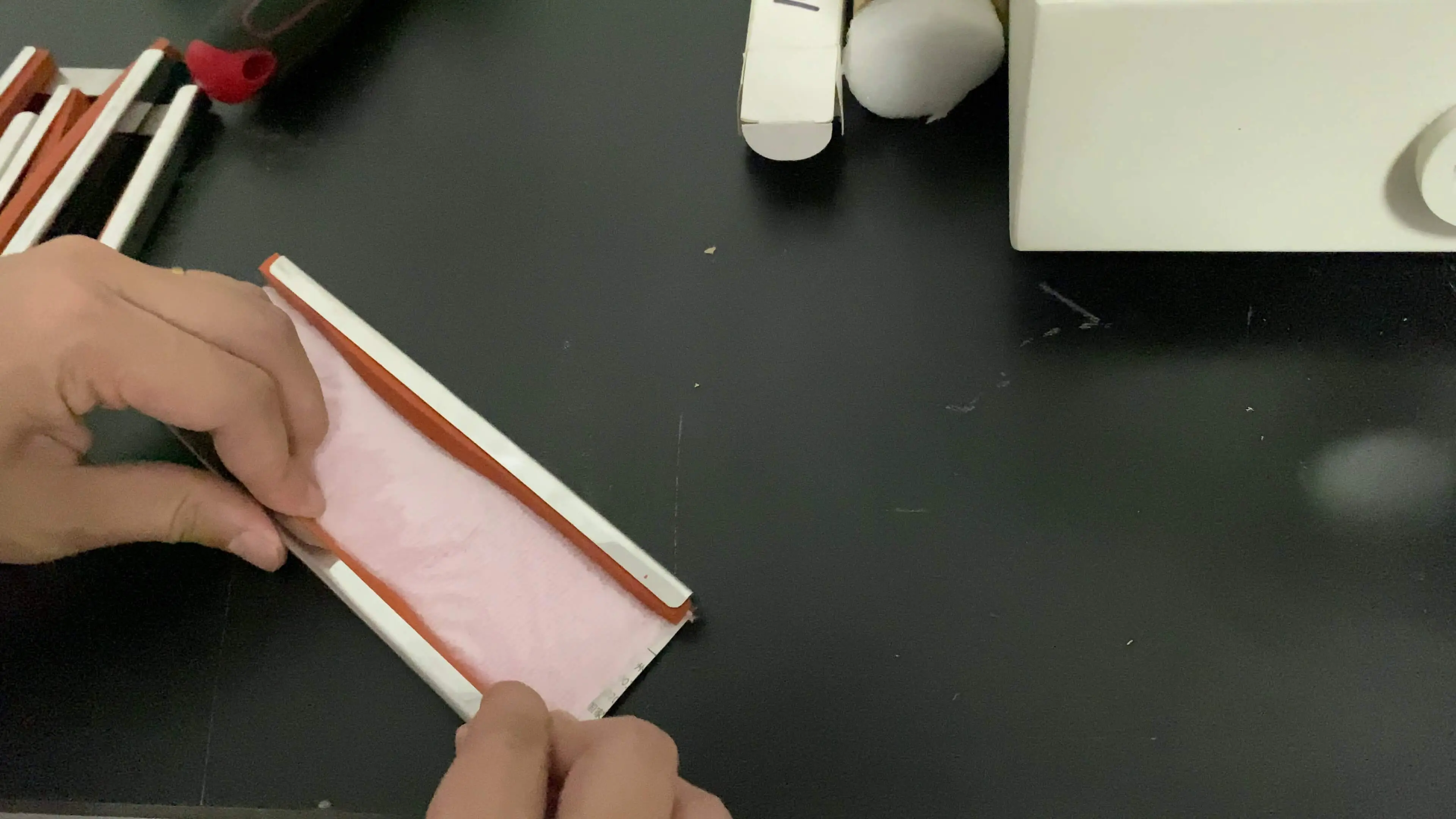

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Home

Home