- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

Double-Cylinder Sample Dyeing Machine Double-Cylinder Prototype Machine D042

Overview

The double-cylinder prototype machine is a pipeline-less environmentally friendly and energy-saving dyeing machine newly designed by our company based on market needs and breaking the traditional concept. Its minimum liquor ratio can reach 1:4-5, and it can be dyed at about 2.5 meters to 3 meters. , can dye two colors at the same time, can adapt to the dyeing and refining of gray fabrics of different weights, and the dyeing effect can fully meet the requirements of large vats. It is a small liquor ratio, environmentally friendly and energy-saving pioneer machine that is in demand in today's market.

Application

Standards

Standards

Key Parameters

|

Model |

|

|

Machine type |

vertical top conveyor, jet overflow type |

|

Number of cylinders |

double cylinders, each cylinder operates independently |

|

Maximum cloth capacity |

double cylinders, each cylinder operates independently |

|

Minimum dyeing cloth length |

2.5 meters (can be adapted to dyeing cloth of different weights) |

|

Working temperature |

room temperature -135℃ |

|

Maximum working temperature |

140℃. |

|

Heating power |

6.6kw/cylinder |

|

Overall dimensions |

(L × W × H) 1200*1060*1700 (mm) |

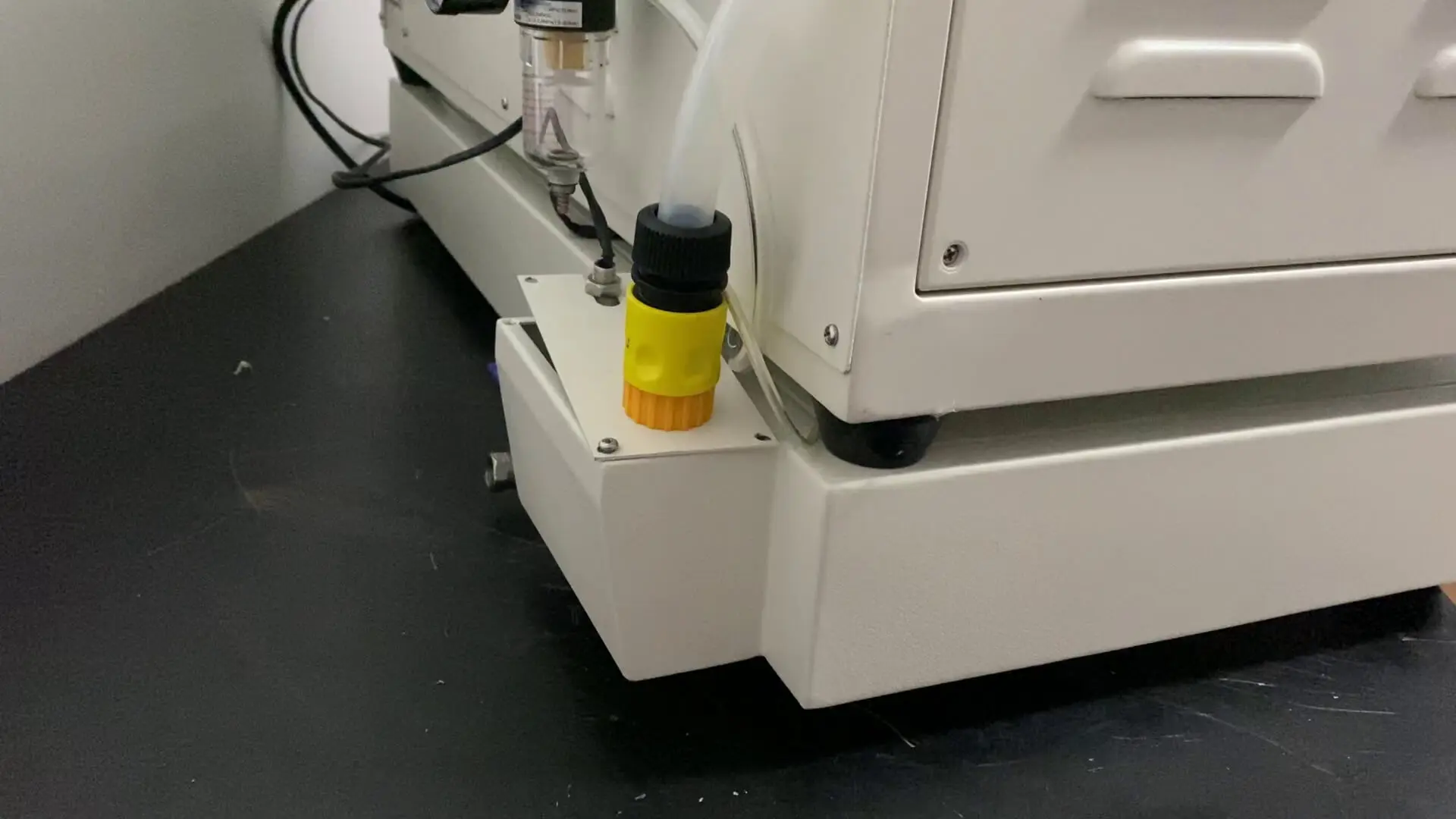

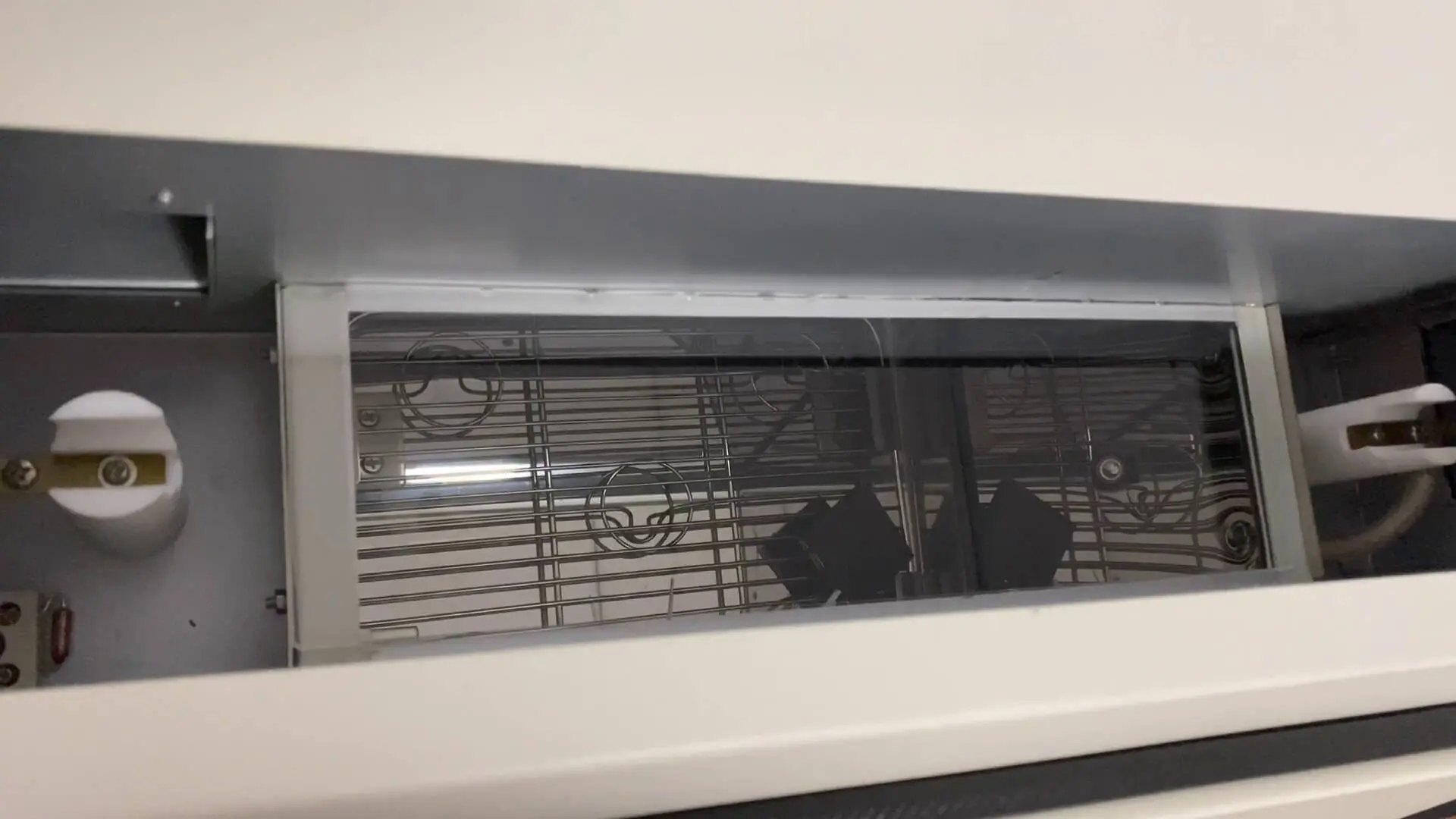

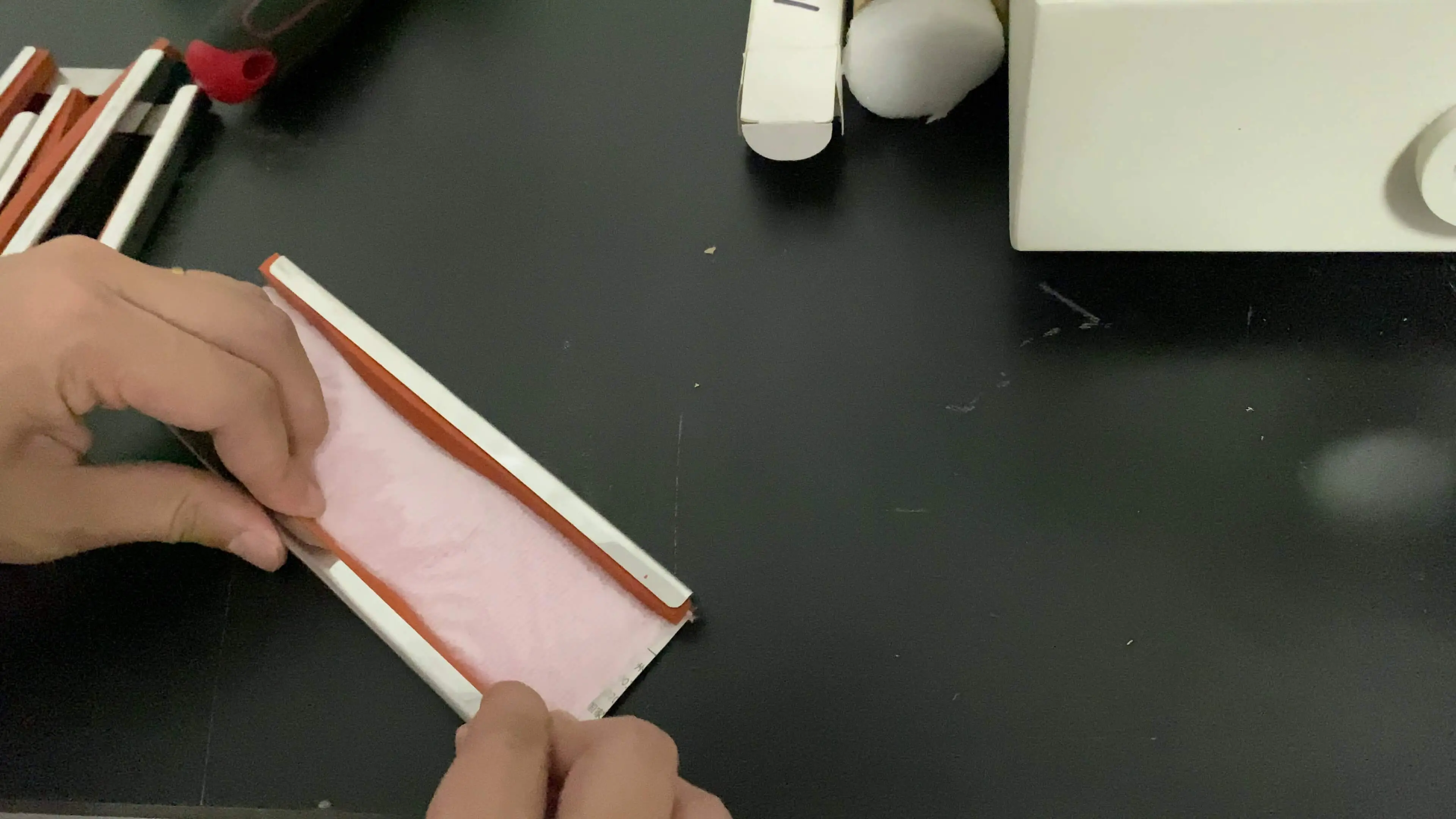

Product Details

Production Processes

Scenarios of Use

Operation

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home