- Plastic And Film Packaging Test Equipment

- Sample preparation

- Carton Package Testing Equipment

- Toys Testing Instrument

- Environmental Testing Equipment

- Footwear Testing Equipment

-

Textile Testing Equipment

- Zipper & Button & Velcro Tape Tester

- Protective Clothing & Mask Tester

- Gloves & Socks Tester

- Feather & Down Tester

- Nonwoven Textile Tester

- Geotextile Tester

- Flammability Test Equipment

- Yarn and FiberTesting

- Washing & Laundering

- Tensile Burst Tear Strength Tester

- Fabric And Garment Testing

- Dyeing and Finishing Tester

- Color Fastness Testing

- Abrasion and Pilling Tester

0102030405

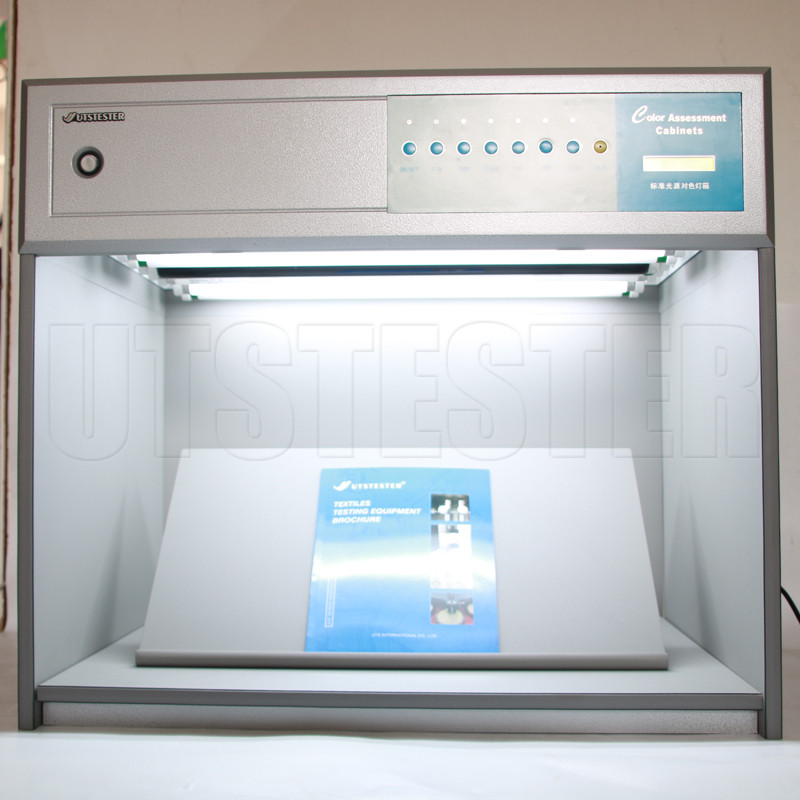

Color Assessment Cabinet Color Matching Cabinets Color Light Box

Overview

Color light box/Color matching cabinet, to do color matching or assessment for all industries and applications where there is a need to maintain color consistency and quality. Such as, Dyeing, Packaging, Printing, Footwear, Inks and Textile, Automotive, Ceramics, Cosmetics, Foodstuffs, Furniture, knitwear, Leather, Ophthalmic,etc.

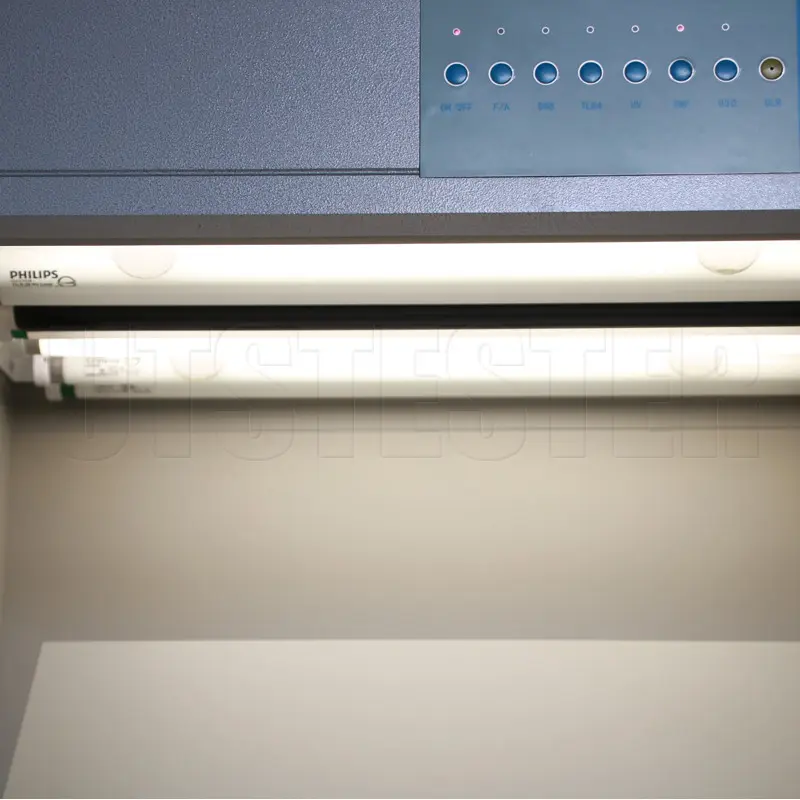

D65, TL84, CWF, F, UV, U30 light sources are available for this light box.

Application

Key Parameters

Light Tube Model

|

Light |

Details |

Quantity |

Power |

Color Temperature |

|

D65 |

International standard Artificial Daylight |

2pcs |

18W |

6500K |

|

A |

American kitchen window lamp, colorimetric reference lamp. |

2pcs |

100W |

2856K |

|

TL84 |

The light source of the special store in the Europe (Marks & Spencer). |

2pcs |

18W |

4000K |

|

F |

Family hotel use light, color reference light source. |

2pcs |

40W |

2700K |

|

UV |

Ultra Violet light source |

1pc |

18W |

wavelength 365nm |

|

U30 |

Warm White store light source (Warm White) |

2pcs |

18W |

3000K |

|

CWF |

Cool White Fluorescent |

2pcs |

18W |

4200K |

Optional Model

| Models | Configured light sources | Weight | Dimensions( L x W x H) |

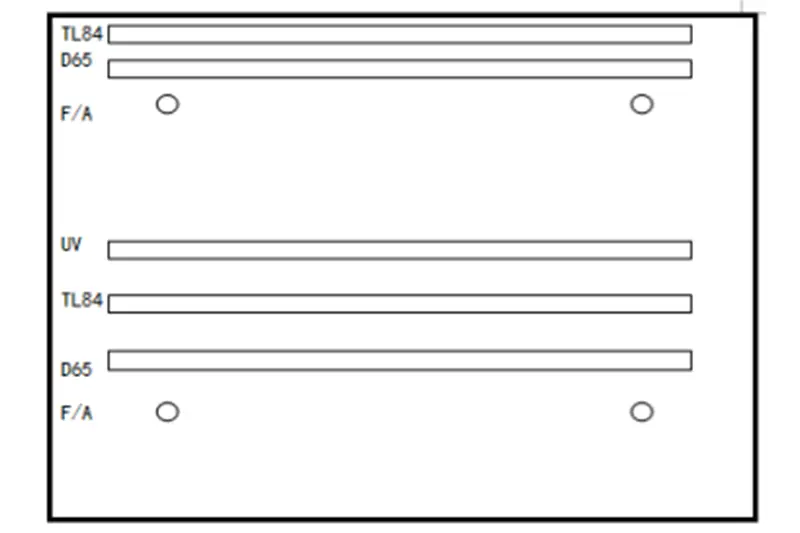

| D008(4) | D65. TL84. F/A . UV | 28kg | 710 x 420 x 570mm |

| D008(5) | D65. TL84. CWF. F/A . UV | 32kg | 710 x 420 x 570mm |

| D008(6) | D65. TL84. CWF. F/A . UV. U30 | 35kg | 710 x 620 x 625mm |

| D008(7) | D65. TL84. CWF. F . UV. U30. A | 35kg | 710 x 620 x 625mm |

| D008(6)-1200 | D65. TL84. CWF. F/A . UV. U30 | 90kg | 1310 x 620 x 800mm |

| D008(7)-1200 | D65. TL84. CWF. F . UV. U30. A | 95kg | 1310 x 620 x 800mm |

Product Details

Production Processes

Scenarios of Use

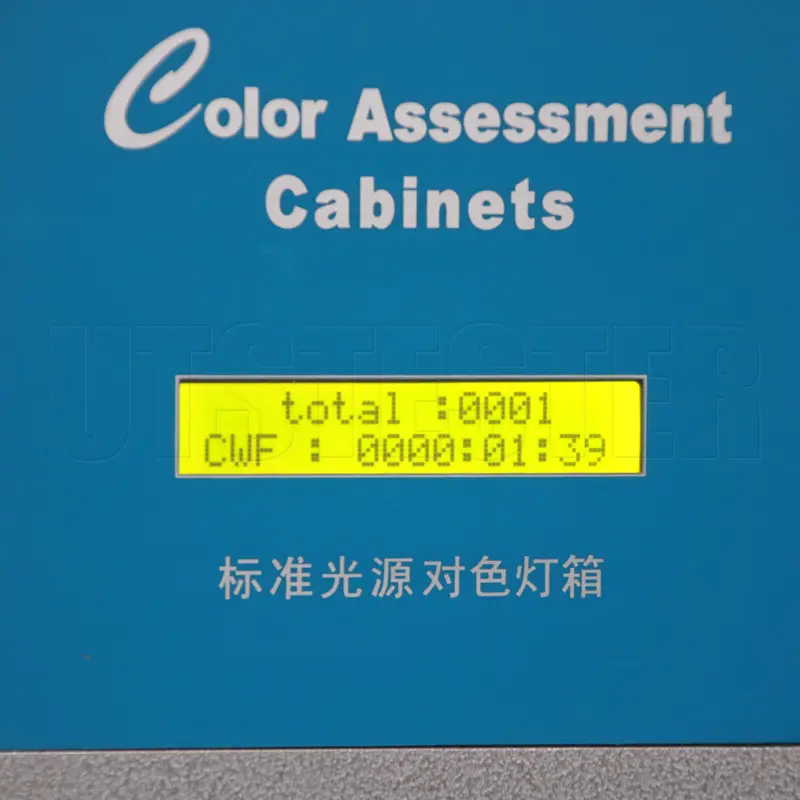

Operation

Press “ON/OFF” key to start

Press “ON/OFF” key for one time and the Timing will display the total service time of this lamp cabinet.

Press the corresponding lamp key

Press D65 key again and D65 lamp lit up. The Timing will display the total service time of D65 lamp.

Lamp group test

In case of pressing F, TL84, or UV key, the corresponding lamp group lit up. And the Timing will display the total service time of this lamp group. In case of using two or more light sources, it`s just to press two key or more keys.

Placement of test objects

Put articles to be checked at the center of the bottom of the lamp cabinet.When comparing the color of two or more articles, don`t observe them by overlapping, but to put them in the cabinet parallel.

Transportation

Packing System

1. Products are covered with air bubble film before put them into composite board standard export wooden case. To ensure waterproof, moistureproof, corrosion, anti-corrosion and security.

2. Package with shipping mark in line with International and national standards, which is easy for handling, loading and unloading.

3. Packing materials selected accorded with economic and safety requirements

4. Compliance with environmental requirements.

Home

Home