0102030405

What is the difference between single column and double column of universal tensile testing machine?

2025-07-05

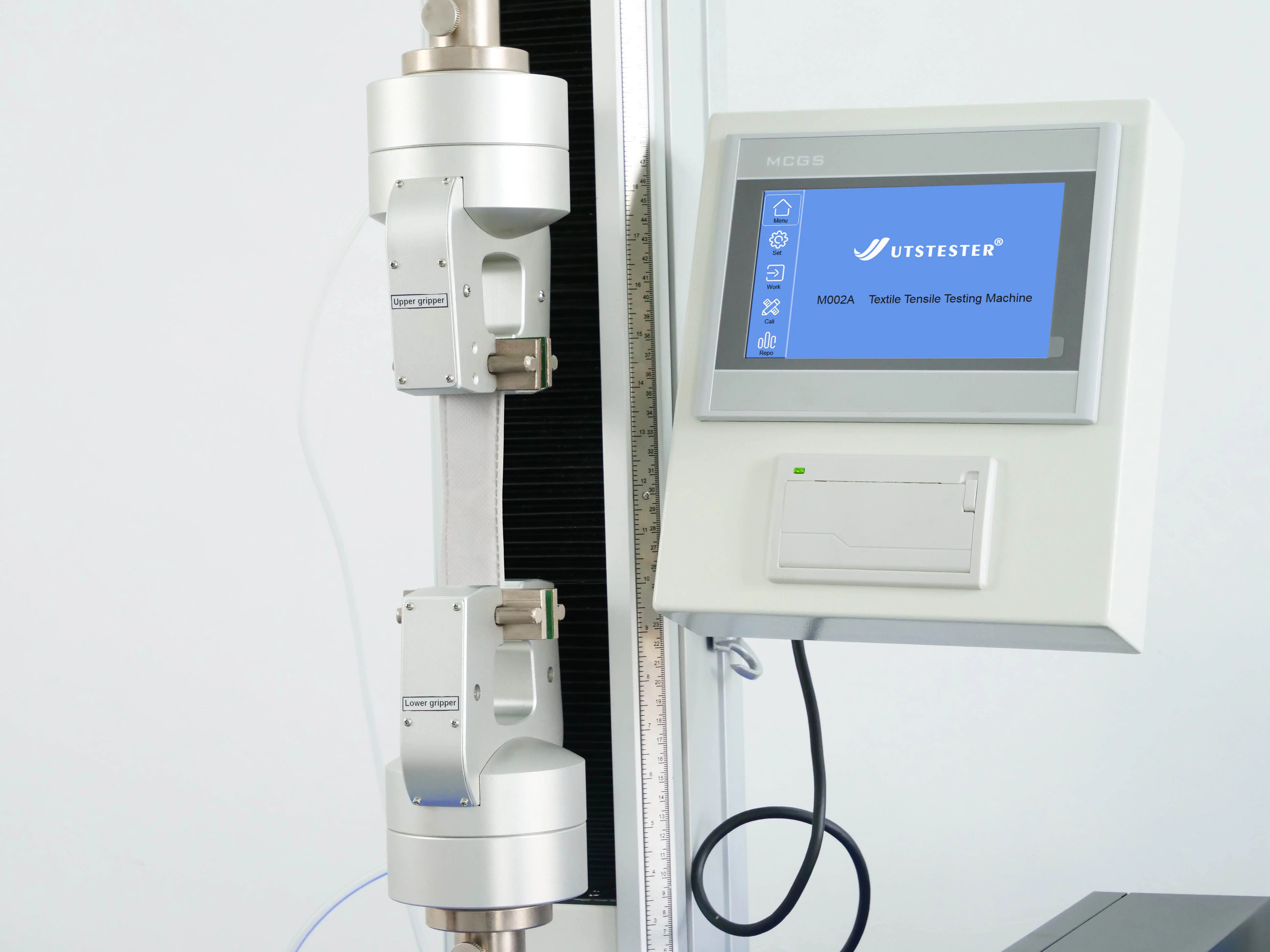

The Tensile Testing Machine is designed for footwear, rubber, plastic, leather, metal, nylon thread, fabric, paper, aviation, packaging, construction, petrochemical and other tensile, compression, bending, shear, adhesive strength, peeling, tearing and other tests and design, electricians, vehicles and other materials.

According to the structure can be divided into single-column and double-column type, both in the design, performance and application scenarios there are obvious differences.

Differences in structural design

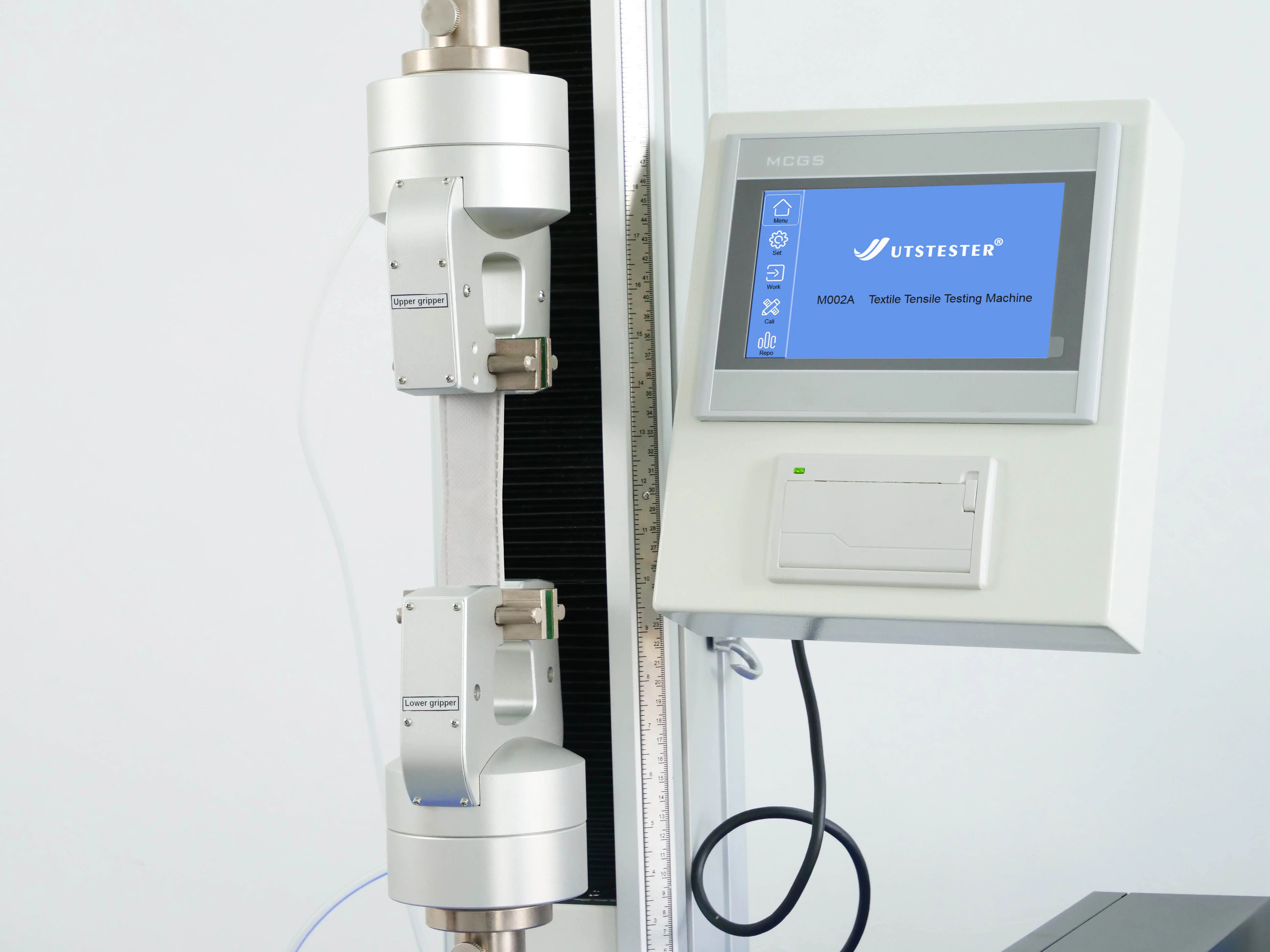

1. Single-column tensile testing machine: a single column (or frame) is used as the main support, the loading system and transducer are usually integrated above the column, and the specimen is mounted between the upper and lower fixtures, with a compact overall structure and small footprint.

Similar to the ‘T’ type or ‘L’ type, the upper part of the loading device, the lower part of the base (fixed lower fixture).

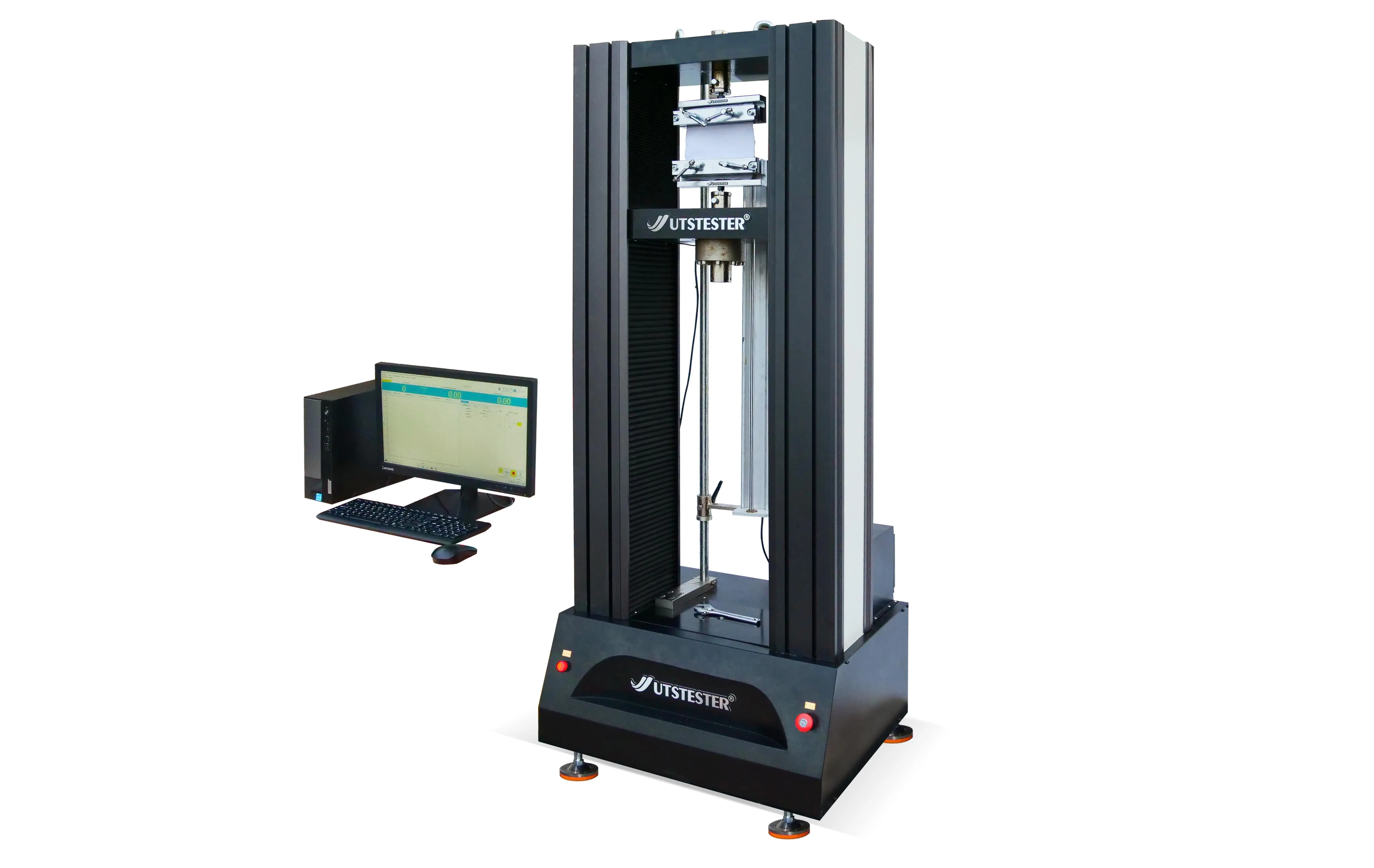

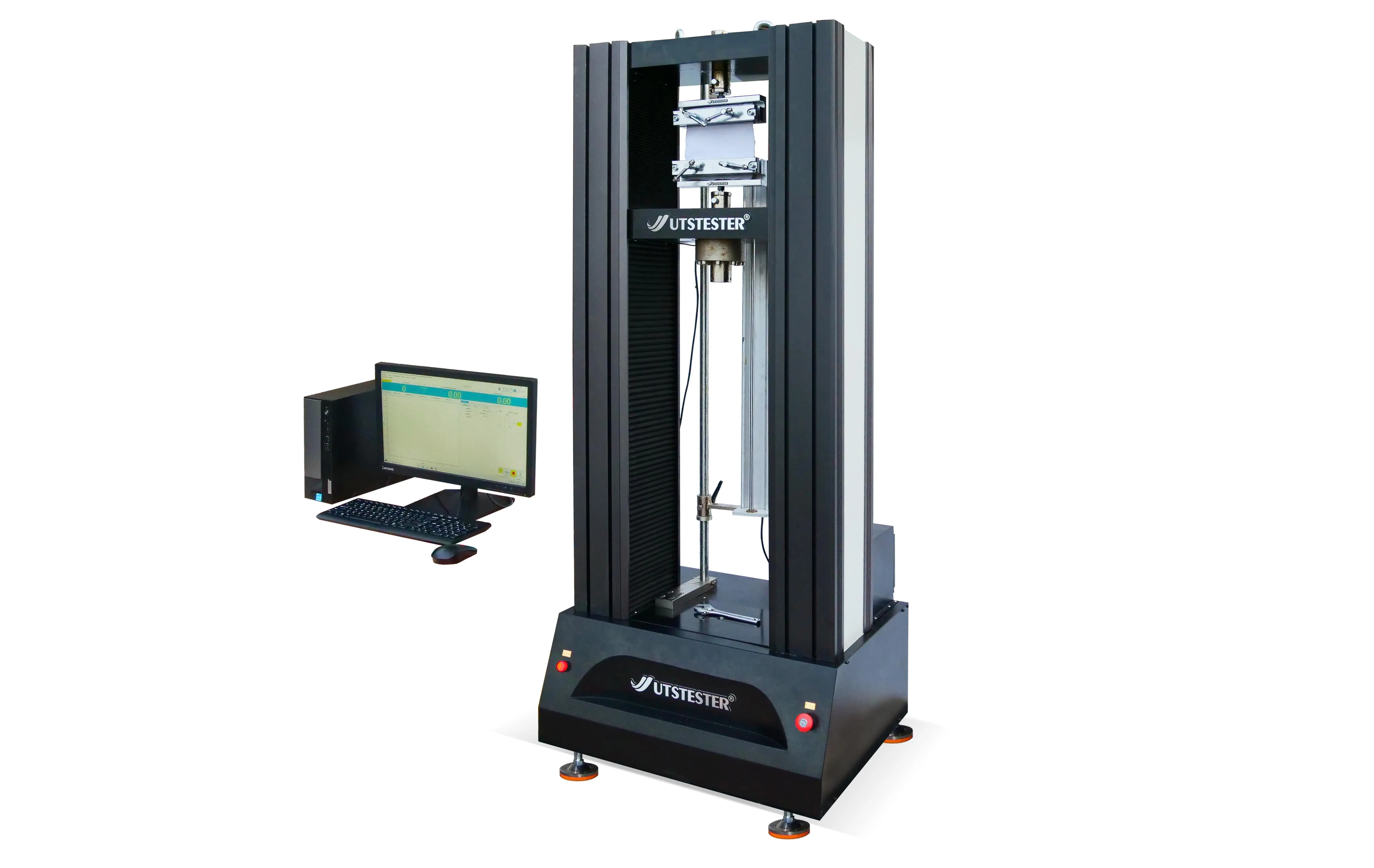

2. Double-column Tensile Testing Machine: Supported by two parallel columns (or frames), the loading system is located at the top, the testing space is formed between the two columns, and the lower fixture is fixed on the base, with a symmetrical and stable structure.

Similar to the ‘door’ type (door structure), two columns perpendicular to the base, the test space is located in the middle, the overall volume is larger.

Load capacity and applicable materials

1.Single-column type: the maximum test force is usually ≤10kN (a few can reach 20kN), suitable for small load test (such as film, fibre, rubber, plastic and other flexible materials), or small parts (such as springs, electronic components) of the tensile and compression test.

2.Double-column type: the maximum test force can cover 10kN-500kN (or even higher), can withstand large loads (such as steel, concrete, automotive parts, etc.), suitable for high-strength materials mechanical properties testing, such as tensile strength, yield strength.

Application: Widely used in aerospace, machinery manufacturing, construction building materials and other industries for quality testing.

Operation and Expandability

1.Single-column type: small size, light weight, easy to move, suitable for laboratory desktop use; but with limited functional expandability (e.g., difficult to install complex accessories, such as high-temperature furnace, Environmental Chamber, etc.).

2.Double-column type: usually equipped with a larger working surface and expansion interface, can be added with an extensometer, high/low temperature environmental devices, dynamic loading system, etc., to support multi-functional testing (such as fatigue test, creep test, etc.).

Summary

The core difference between single-column and double-column Tensile Testers lies in the load capacity, precision and structural design, the former is suitable for small load and low precision scenarios, while the latter is suitable for large load, high precision and complex testing needs. The selection should be based on the material characteristics, testing standards, budget and functional requirements of a comprehensive judgement to ensure that the equipment performance and application scenarios match.

Home

Home