EN 388: 2016 Test standards for protective gloves against mechanical hazards

2025-03-25

I. Overview of EN 388: 2016

EN 388: 2016 is the authoritative European standard for the mechanical properties of protective gloves. It specifies the test methods and performance levels of gloves in terms of abrasion resistance, cut resistance, tear resistance, puncture resistance, etc. Its purpose is to help users and consumers make informed decisions when choosing gloves for specific tasks and applications.

II. Application of EN 388: 2016

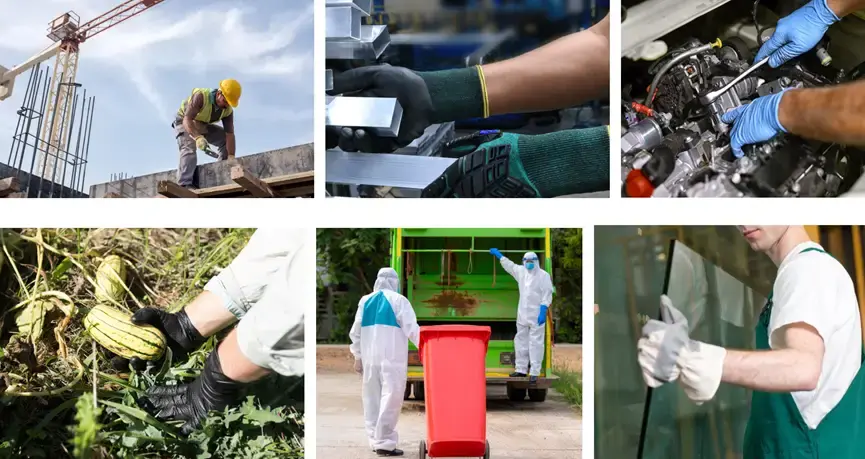

EN 388 is primarily used to classify and rate the ability of protective gloves to resist mechanical hazards. It applies to gloves designed to resist these mechanical hazards. Here are some examples of industries and applications where gloves that meet the EN 388 standard may be used:

1. Construction: Workers in the construction industry can use gloves that meet the EN 388 standard to protect their hands from abrasions, cuts and punctures when handling building materials, power tools and sharp objects.

2. Manufacturing: In manufacturing facilities, gloves rated to EN 388 are often used to protect workers' hands from mechanical risks when operating machinery or handling metal, glass or other sharp materials.

3. Metalworking: Workers in the metalworking and machining industries often need cut-resistant gloves to protect against sharp edges and metal shavings.

4. Automotive: Mechanics and workers in the automotive industry need gloves that meet the EN 388 standard to protect against cuts, abrasions and punctures when working with sharp tools and automotive parts.

5. Agriculture: Farmers and agricultural workers can wear such gloves to protect their hands from thorns, abrasive plant materials and other mechanical hazards when performing various agricultural tasks.

6. Waste Management: Workers in the waste management and recycling industries can use gloves that meet the EN 388 standard to prevent punctures and abrasions when handling sharp or hazardous materials.

7. Glass Handling: Professionals in the glass industry, such as glaziers, often need to use gloves with high cut resistance to safely handle glass sheets.

8. Warehousing and Logistics: Workers in warehouses and logistics centers need to use gloves to protect their hands when handling boxes, packages and pallets that may have sharp edges or protrusions.

9. Carpentry: Carpenters and woodworking professionals use gloves to prevent cuts and flying wood chips when handling wood and using sharp tools.

10. Security and Law Enforcement: Security guards and law enforcement officers can wear gloves that meet the EN 388 standard to prevent punctures from sharp objects or materials when searching or handling potentially hazardous items.

12.General Maintenance and DIY: For home renovations and do-it-yourself (DIY) projects, individuals can choose gloves that meet the EN 388 standard to protect their hands when working with tools or materials.

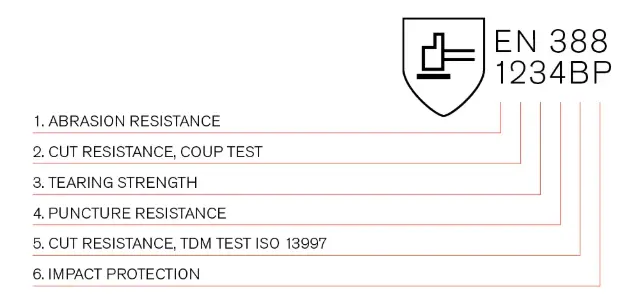

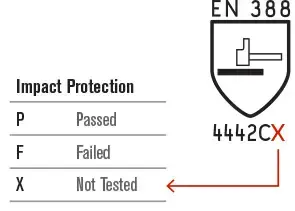

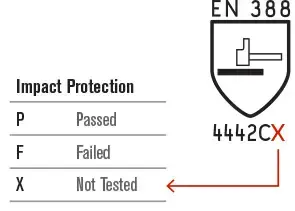

Gloves that comply with EN 388:2016 must pass the EU PPE Regulation (2016/425) and select the certification mode according to the risk level (e.g. Class II requires review by a notified body). Gloves that comply with EN 388:2016 use pictograms and codes (e.g. "4 5 4 3 P") to clearly indicate the performance level, allowing users to quickly identify applicable scenarios.

III. EN 388: 2016 Tests

1. Abrasion resistance test: Use standard sandpaper (100 mesh) to rub the glove material at a fixed pressure (9 kPa) and record the number of revolutions required for the material to be worn through. The larger the number, the better the abrasion resistance.

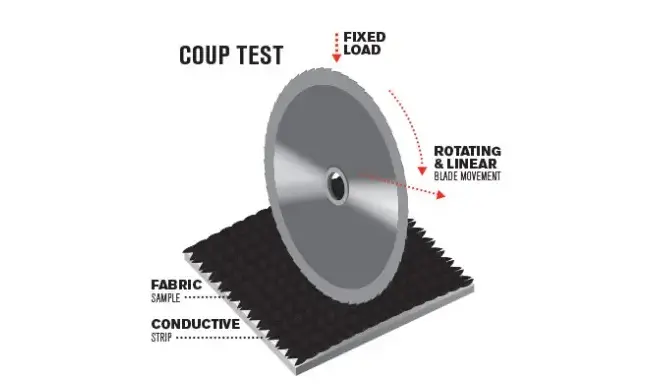

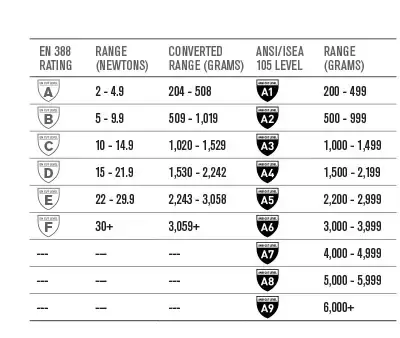

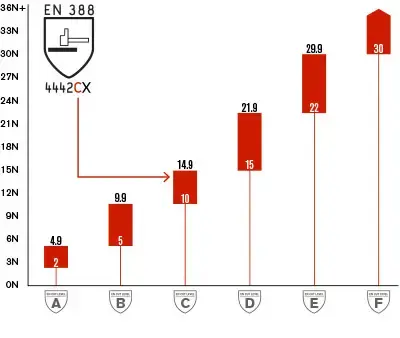

2. Cutting resistance test: EN 388:2016 includes two test methods, which are selected based on material properties:

(1) Coup Test (rotating blade method): Use a rotating circular blade (diameter 45 mm, speed 5 rpm) to cut the material at a fixed pressure (5N) and calculate the cutting index (number of cuts/number of cuts of the standard reference material).

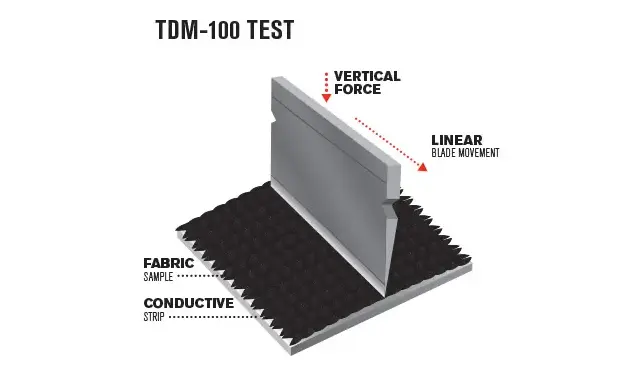

(2) TDM-100 method (ISO 13997): Use a sharp blade (20 mm long) to cut the material at a constant speed (100 mm/min), gradually increase the force until the cut reaches 20 mm, and record the required force (Newton).

3. Tear resistance test: Make the glove material into a standard specimen (long strip notch), use a tensile machine to stretch it at a speed of 100 mm/min until it is completely torn, and record the maximum force (Newton).

4. Puncture resistance test: Use a standard steel nail (diameter 4.5 mm, tip radius 0.5 mm) to puncture the material at a speed of 100 mm/min, and record the maximum penetration force (Newton).

5. Impact protection test: according to EN 13594:2015 standard, evaluate the cushioning ability of gloves to impact. Passing the test is marked with a “P” at the end of the code.

Utstester can provide testing instruments and related services that comply with the EN 388: 2016 test system.

Home

Home