0102030405

Tests For Yarn Twist and Factors Affecting The Tests

2025-06-12

Spinning staple fibres into a continuous yarn requires twisting, whereby the fibres are brought together to maintain a certain degree of aggregation, thus imparting a certain strength to the yarn.

The filaments in a composite yarn also need to be lightly twisted; if there is no aggregation force to hold them together, they will come apart or suffer scuffing in use. In addition, depending on the needs of the application, strands and cables can be formed by twisting several single yarns in parallel to make them more uniform as well as structurally stable to withstand higher loads.

Fancy yarns can be formed when two or more yarns are twisted and fed at different speeds and tensions, or when yarns of different colours or patterns are twisted together. Twisting is a method of bringing together bundles of fibres, filaments or individual yarns to enable textiles to withstand stress, strain and friction during manufacture and use, and to give textiles a distinctive appearance. Tests for Yarn Twist and Factors Affecting the Tests Tests for Yarn Twist and Factors Affecting the Tests

1. The concept of twist

In addition to affecting the tensile properties of the yarn, the twist size will also affect the diameter, specific volume, softness and stiffness of the yarn, and the covering properties, warmth, crease recovery, dye absorption rate and permeability of the fabric. Twisting also affects the hairiness of the yarn surface, therefore, twist is an important indicator of the structural characteristics of the yarn.

In addition to the twist and twist factor indicating the twisting characteristics of the yarn, the direction of twist in the yarn is also very important. The direction of twist refers to the direction of inclination of the fibres in the twisted singles or singles in the twisted strands.

There are two types of twist in yarn: S-twist, or clockwise twist, and Z-twist, or anti-clockwise twist. Z-twist is generally used for single yarns, while S-twist is commonly used for plied yarns.

2. Twist Measurement Methods

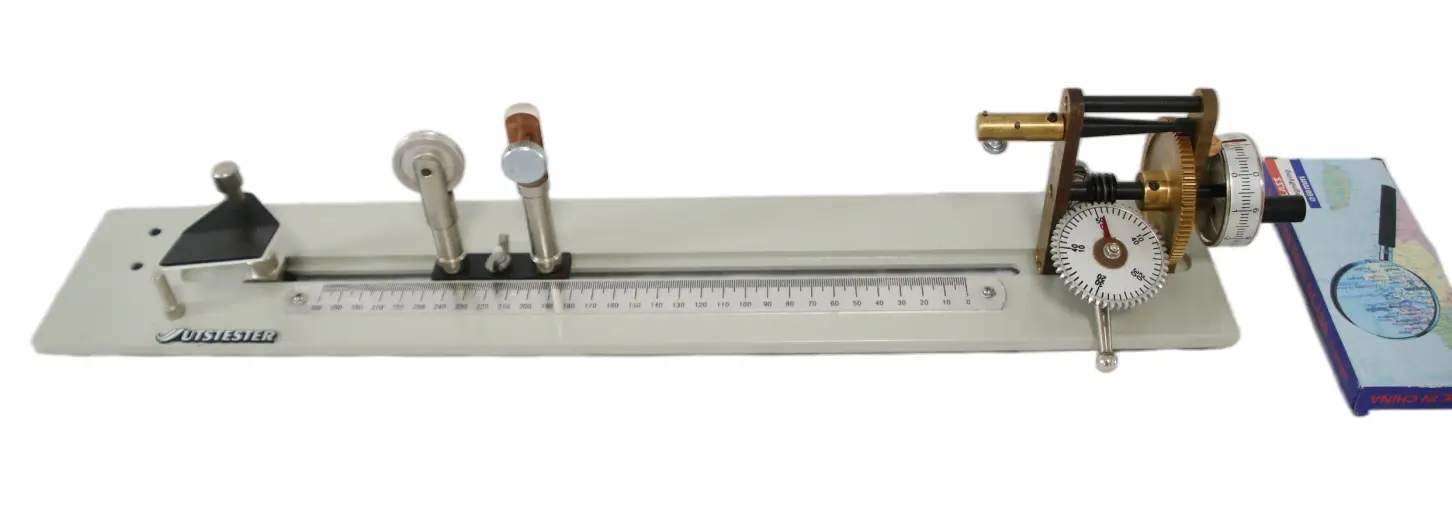

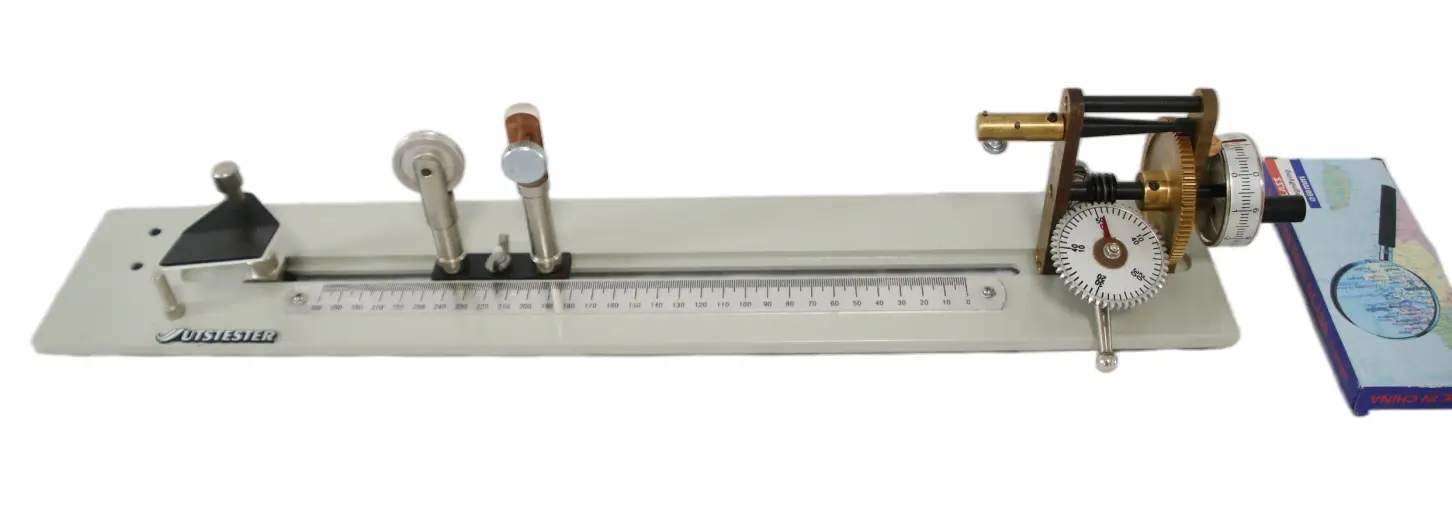

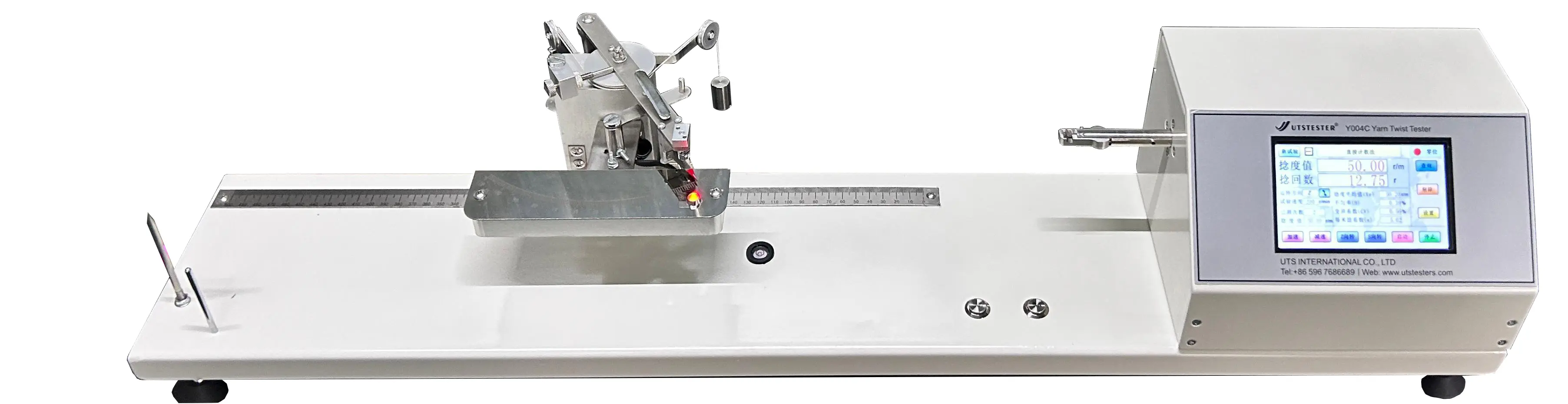

There are two commonly used twist test methods: direct counting method and untwisting and twisting method.

Short fibre, strand test is generally used direct counting method, while the yarn is twisted method, in addition to the second and third time twisting and twisting method, slip method and so on.

2.1 Direct counting method

One end of the specimen is fixed, the other end of the direction of twisting back until the fibres in the yarn are completely straightened and parallel until the retreat of the twist that is the length of the specimen for the number of twists. The direct counting method is the most basic method for determining the twist of yarn, and the results are relatively accurate, often used as a standard for assessing the accuracy of other methods.

2.2 Retreating and twisting method

Retreating and twisting method is assumed to be carried out on the premise that under a certain tension, the amount of yarn elongation after untwisting is the same as the amount of yarn shortening when twisting in the reverse direction.

3.Factors affecting twist test

3.1 Pre-added tension

There are different regulations on the pre-added tension of the reverse twist method at home and abroad. Too large pre-tension will make the pointer reset to zero slowly when reverse twisting, thus increasing the twist of reverse twisting and producing fibre slip in advance in the slip method;

On the contrary, if the pre-tension is too small, the twist of reverse twisting will be relatively reduced, which will make the value of the test of untwisting and twisting method on the low side. In the slip method and the secondary back-twisting and twisting method, because of the consideration of the error caused by this tension change, the method of subtracting the error of the two specimens is adopted, so it is less affected by the tension.

3.2 Allowable elongation value

The sample elongates after the yarn has been untwisted, and the allowable elongation value set for the elongation limit prevents the fibre slip of the yarn during the untwisting process. Experiments show that the larger the allowable elongation value, the larger the measured twist value in the untwisting and twisting method, and the larger the allowable elongation value, the fibre slippage at the weak ring of the yarn will obviously affect the correctness of the experiment.

The allowable elongation value is related to the twist coefficient, the larger the twist coefficient of the yarn is, the larger the allowable elongation value can be selected; on the contrary, it should be smaller. Usually the twist factor of the yarn does not vary much, so the difference in the permissible elongation value will not be too big.

3.3 Uneven Yarn Strip

Uneven yarn strip will have an effect on the twist test. If there are defects such as cotton knots and bamboo knots on the yarn, the original twist on the yarn will be twisted in the reverse direction before the original twist is removed, thus increasing the testing error. The presence of uneven length segments on the yarn will affect the correctness of the applied tension and eventually cause additional testing errors.

Home

Home