0102030405

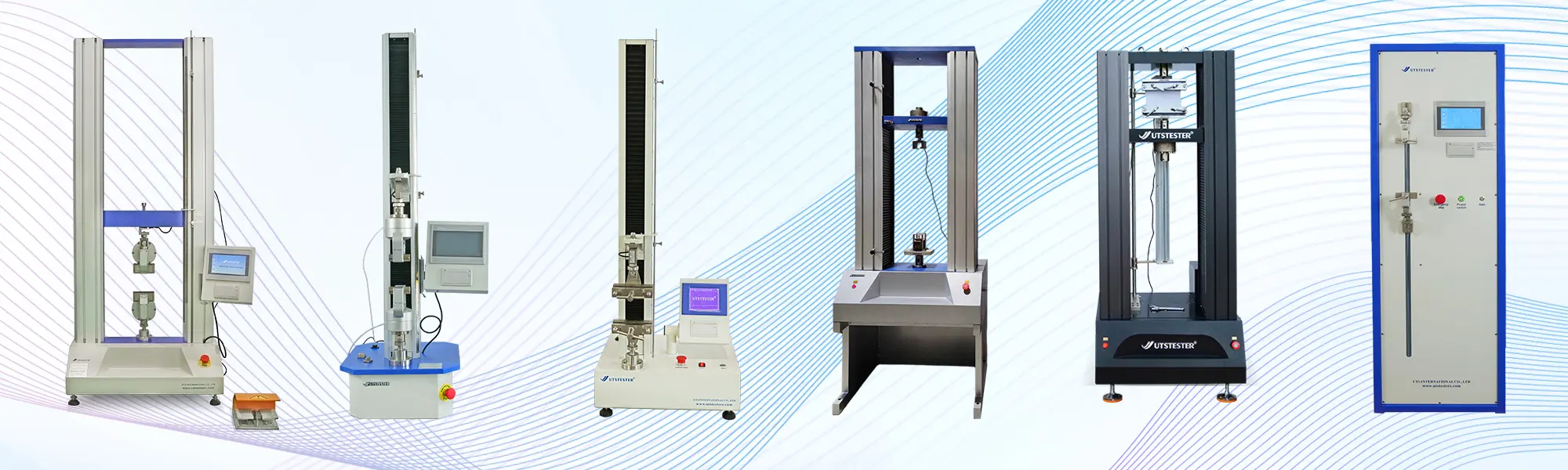

Tensile testing machine, how should I choose?

2025-07-01

1. The test force range of the test machine selection: customers in the choice of Tension Testing Machine, not quite clear how much range to choose the test machine, if the range of large test force value is not enough precision, like a small sesame with a large scale, the range is small to achieve the purpose of measuring the specimen, on the contrary, there will be damage to the tension machine.

Tensile Testing Machine selection first of all depends on the customer is to do what the material test, and secondly also look at the thickness of the specimen, thickness, width, the specimen can probably withstand how much force that the material's conventional strength range.

Tensile testing machine test range is not the same, the user should be based on their own test samples to determine. When choosing, it should be noted that the effective measuring range of the tensile testing machine is 1%-100% FS, but UTSTESTER's M model tensile testing machine can reach 0.2%-100% FS. For example, 5KN tensile testing machine, the effective testing range is between 10N-5KN, less than 10N will have error, you can increase the testing range by adding a different value of the force of the The test range can be increased by adding sensors with different force values.

2.Test machine extensometer selection: test machine elongation selection depends on the specimen material and type. Generally speaking, metal (except aluminium profiles) and other elongation of the specimen is small, with a small deformation of the extensometer measurement. Aluminium profiles, elastomers, rubber and plastics, polymers and other specimens with high elongation are measured with a large deformation extensometer. Dumbbell specimens of metal sheets or bars are measured with a small deflection tensiometer. There are also some do not need to use the extensometer. Such as round, metal sheet elongation after break, with a ruler splicing measurement. General rectangular, rectangular bar specimens, the displacement method to find the elongation.

3. Selection of fixture: the selection of Universal Testing Machine fixture depends on the specimen material and test method standard. According to the different test methods, can be divided into: tension class fixture, compression class fixture, bending class fixture, peeling class fixture, shear class fixture, etc., of which the tension class fixture accounted for about 80% of the total number of fixtures. According to the different structure, can be divided into wedge type fixture, clamping type fixture, winding type fixture, eccentric type fixture, lever type fixture, shoulder type fixture, bolt type fixture, 90°/ 180°peeling type fixture. The structure of these fixtures have their own advantages and disadvantages, for example: wedge clamps, the beginning of the clamping force is small, with the increase in the value of the test force and increase. Clamping fixture, the beginning of the clamping force is small, with the increase in the value of the test force and reduce.

For universal testing machine clamps for special requirements or do not know how to choose, you can consult UTSTESTER customer service or engineers selection.

Home

Home