0102030405

How to evaluate the quality of geosynthetic materials? What are the testing methods for geosynthetic materials?

2025-08-20

Geosynthetic material testing refers to the testing and evaluation of various physical, mechanical, and engineering properties of geosynthetic materials. These tests aim to determine the characteristics of geosynthetic materials to ensure their reliability and suitability for use in engineering projects.

1. Geotechnical Material Testing Items

Physical and Chemical Properties: Density, Right-Angle Tear Load, Puncture Resistance, Carbon Black Content, Carbon Black Dispersion, Atmospheric Pressure Oxidation Induction Time, Low-Temperature Impact Resistance, Catalytic Performance, Water Vapor Permeability Coefficient, Dimensional Stability, etc.

Mechanical Properties: Tensile strength and elongation, tensile elastic modulus, flexural strength, flexural elastic modulus, compressive strength, cantilever beam impact strength, simply supported beam impact strength, shear strength, tear strength, peel strength, puncture resistance, Shore hardness, Rockwell hardness, ball indentation hardness, drop weight impact, environmental stress cracking resistance, etc.

Thermal properties: Melting point, oxidation induction time, melt flow rate, heat deflection temperature, Vicat softening temperature, coefficient of linear expansion, oxygen index, thermal stability, softening point, etc.

Electrical properties: Dielectric constant, dielectric loss factor, volume resistivity, surface resistivity, etc.

Weatherability: Aging tests (UV, xenon lamp, carbon arc lamp, etc.), salt spray tests (neutral salt spray, acidic salt spray), liquid resistance tests (water resistance, acid resistance, alkali resistance, salt resistance, organic solvent resistance, oil resistance, etc.), thermal aging, etc.

2. Geotechnical material testing instruments

To ensure the accuracy and scientific rigor of testing, the testing of geosynthetic materials requires the use of common instruments, including:

Tensile Testing Machine: Used to test the tensile strength, elongation at break, and tensile strength of materials.

Permeability Tester: Used to measure the permeability of geosynthetic materials, typically assessed using porosity and permeability coefficient.

Abrasion Tester: Used to test the abrasion resistance of geological materials.

Dynamic Penetration Tester: Used to test the puncture resistance of geotextiles, geotextile fabrics, and related products against a steel cone dropped from a fixed height.

Effective Pore Size Tester: Used to measure the apparent open pore rate of single-layer geotextiles or geotextile-related products.

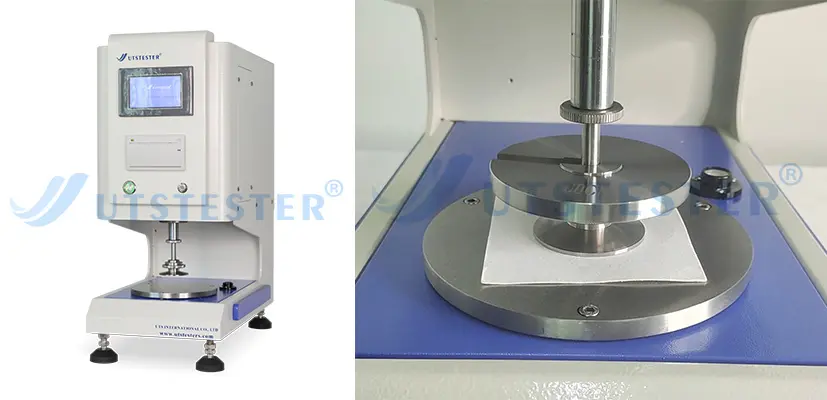

Geotextile Thickness Measurer: Used to determine the thickness of geotechnical films, sheets, and other non-embossed and non-corrugated materials under different pressures and specified time intervals.

3. Geotechnical material testing methods

Tensile Testing Machine: Place the material sample in the tensile testing machine and apply gradually increasing tensile force until the sample breaks. Calculate parameters such as tensile strength and elongation at break based on the test data.

Permeability Test: Measure the rate at which water flows through the material using a permeability tester. Obtain the material's permeability coefficient according to standard testing methods. Standards: GB/T15789-1995 ASTM D4491-2017

Dynamic Puncture Test: Drop a stainless steel cone of specified mass from a height of 500 mm onto the sample surface to create a hole. Insert a graduated angle cone into the hole to measure the penetration depth. Standards: GB/T 17630 ISO 13433

Geotextile thickness measurement: Apply a specific pressure to a specific area of the sample. After a specific time, measure and read the vertical distance between the two plates; this value is the measured thickness of the sample. Standard: ASTM D5199

Home

Home