0102030405

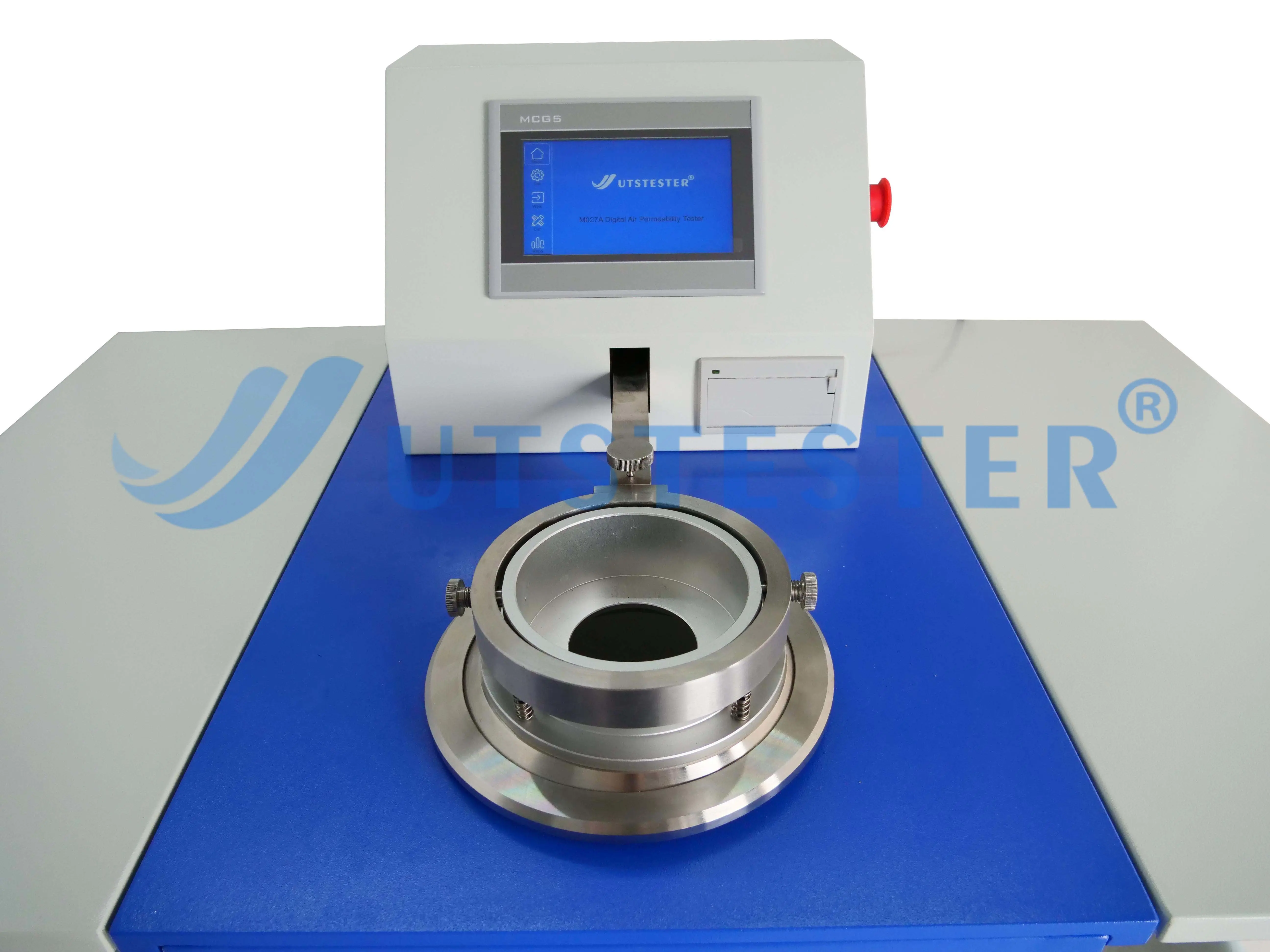

Fabric air permeability tester

2025-07-25

The significance of fabric Air Permeability test

Air permeability is a physical index that characterizes the air permeability in the tested sample, mainly for porous materials with large air permeability, such as textiles, sponges, leather, etc. For fabric materials, the air permeability is related to the number and size of the gaps between the warp and weft yarns and the gaps between the fibers, the warp and weft density, the yarn twist, the fiber properties, the yarn structure, the fabric thickness and other factors.Different requirements for fabrics have different air permeability according to their specific uses. For example, the air permeability of fabrics used to make parachutes should be strictly controlled within the specified range. If the air permeability is too large, the parachute cannot be fully inflated. If the air permeability is too small, the stability of the parachute is poor or even damaged. Fabrics used as carpets are required to have relatively high air permeability. Even if they are all fabrics for making clothes, their air permeability should also vary to ensure that the clothes are comfortable to wear. For example, summer clothes should have a large air permeability and good heat dissipation, while winter coats should have a small air permeability to improve the warmth retention effect. Therefore, appropriate air permeability is one of the prerequisites for fabrics to have good performance.

Test principle of fabric air permeability test

According to the specified method and parameters, clamp the sample at the air inlet of the fabric air Permeability Tester, and then adjust the fan speed to achieve a pressure difference on both sides of the fabric. The air permeability of the breathable fabric is determined based on the nozzle aperture and the size of the pressure difference on both sides. The air permeability refers to: the gas flow rate per unit area of the fabric vertically per unit time under the specified pressure difference, in units of mm/s, and the performance of air passing through the fabric when there is a pressure difference on both sides of the fabric. This is called air permeability.

Test steps for fabric air permeability test

First, cut the fabric sample to be tested into the specified size, ensuring that the sample surface is flat and wrinkle-free. Then fix the fabric sample in the test area of the fully automatic air permeability tester.

Next, set a specified pressure difference on the tester, which is usually adjusted according to the test standard and fabric characteristics.

Then start the tester and measure the air flow through the fabric under the set pressure difference. The test results are expressed in volume flow units, such as cm's or L/min.

Finally, the tester automatically records the measured data and calculates the air permeability index of the fabric. According to different test standards, air permeability can be expressed as air flow or air permeability.

To ensure the accuracy and comparability of test results, various countries and regions have established multiple Air Permeability Test Standards. Common standards include the ASTM D737 standard of the American Society for Testing and Materials, the IS0 9237 standard of the International Organization for Standardization, and the Chinese national standard GBTT5453. These standards have detailed provisions for sample preparation, test conditions, data processing, etc. to ensure the scientificity and consistency of test results.

As a precision testing equipment, the automatic air permeability tester plays a vital role in testing the air permeability of textiles. Through scientific and rigorous testing methods, it can accurately evaluate the air permeability of fabrics and ensure product quality and effect. If you want to know more about this machine, please feel free to consult UTSTESTER.

Home

Home