0102030405

Environmental test chamber: temperature and humidity test chamber test and test standards

2025-06-13

Combined temperature and humidity cycling test is to expose the samples to the set temperature and humidity alternating test environment, to evaluate the samples through the temperature, humidity environment cycling or storage of the functional characteristics of the changes.

The environment in which the product is stored and worked in has a certain temperature and humidity, and it will change constantly. For example, the temperature difference between day and night, different humidity at different temperatures and different times, and different temperature and humidity areas during the transport of products. This alternating temperature and humidity environment will affect the performance and life of the product and accelerate the aging of the product. The temperature and humidity cycle simulates the temperature and humidity environment in which the products are stored and worked, and checks whether the products are affected in this environment for a period of time within an acceptable range.

It is used to test the quality of mobile phones, plastic products, metals, food, chemicals, building materials, medical, aerospace and other products.

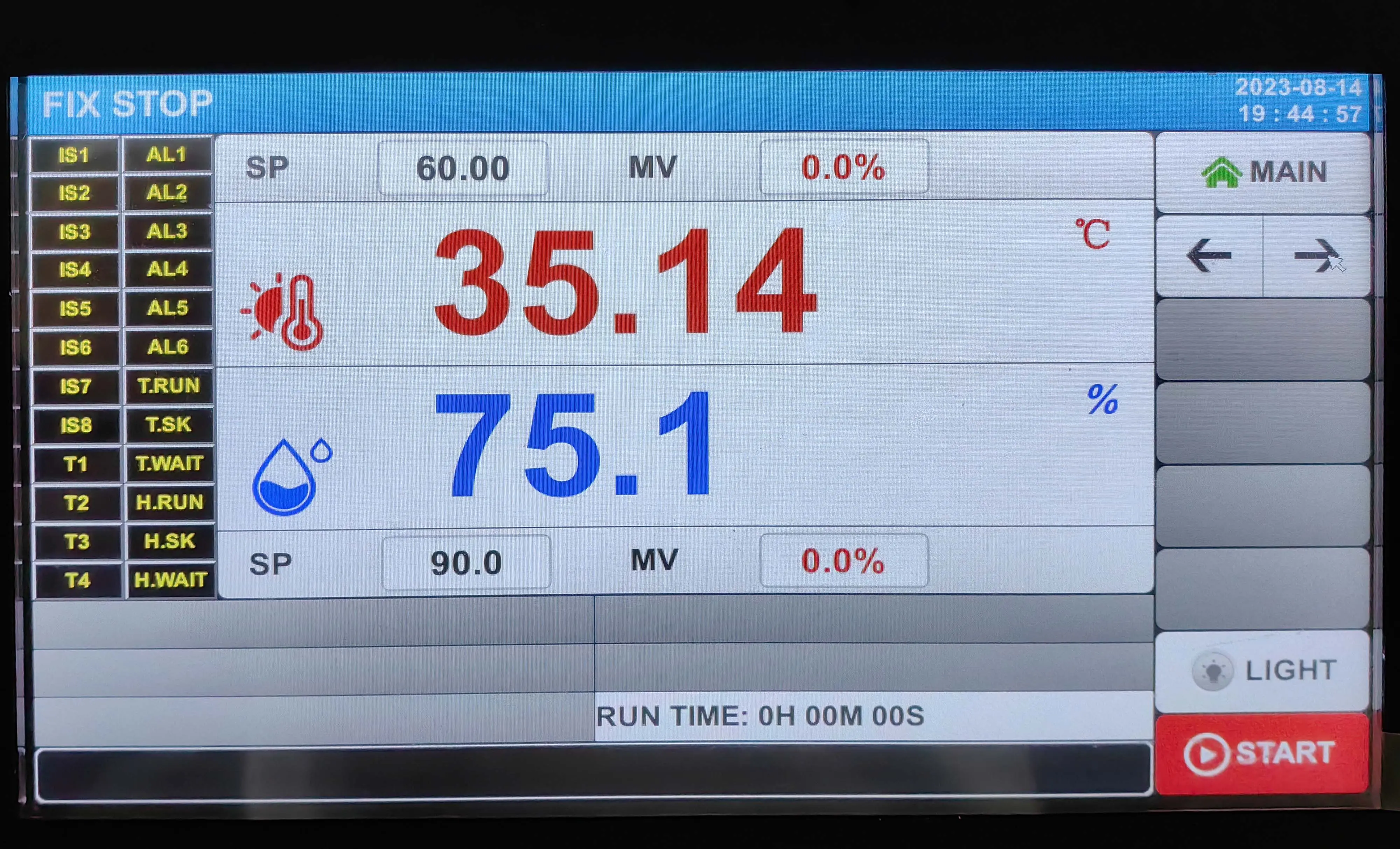

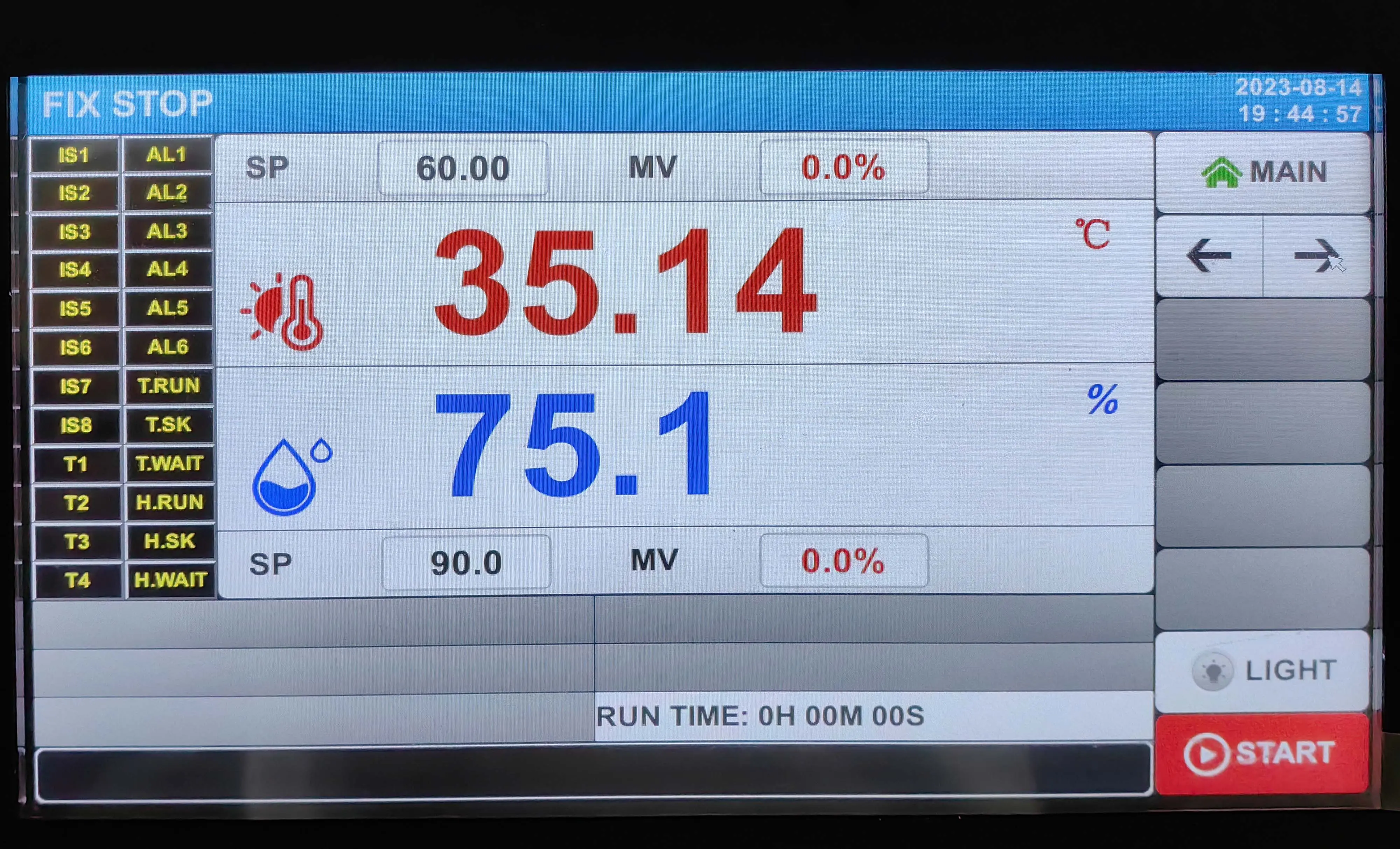

Temperature and humidity test chamber mainly for Constant Temperature And Humidity test and temperature and humidity cycle test

1. Constant temperature and humidity test

Test purpose: to assess the adaptability of products for use and storage under hot and humid conditions, observe the impact of test samples at constant temperature, no condensation, high humidity environment for a specified period of time, in order to accelerate the evaluation of the test samples to resist the effect of hot and humid deterioration.

Test equipment: constant temperature and Humidity Chamber

Test conditions: test temperature; test humidity; test time.

Commonly used preferred temperature/humidity: 40℃, 85%; 40℃, 93%; 85℃, 85%, etc.; commonly used

preferred test time: 48h, 96h, etc.

2. Temperature and humidity cycling test

Test Purpose: Applicable to determine the suitability of the test specimen for use and storage under hot and humid conditions of temperature cycling changes and surface condensation.

Test conditions: Selection of temperature, humidity, number of cycles, rate of temperature change and duration.

Temperature and humidity cycle main effects:

1. Expansion of the material by water intake

2. Loss of physical strength

3. Change in chemical properties

4. Degradation of insulation properties

5. Corrosion of machine parts and failure of lubricants.

6. Oxidation of materials

7. Loss of plasticity

8. Acceleration of chemical reactions

9. Degradation of electronic components

Method Standard

Temperature and Humidity Cycling Test Standard Reference: GB/T 2423.34, IEC 60068-2-38, EN 60068-2-38, etc.

Home

Home