0102030405

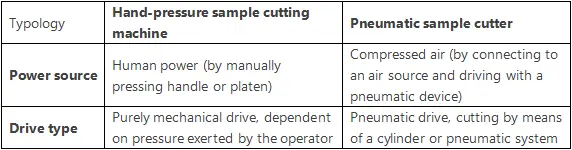

Difference between Hand Pressure Sample Cutting Machine and Pneumatic Sample Cutting Machine

2025-05-16

Hand-pressure sample cutter and pneumatic sample cutter are two common material cutting machines, combining abrasion, pilling, strength, washing, stiffness and other tests to cut samples of specified sizes, for cutting round or irregular samples of all kinds of wool, cotton, synthetic fibres and knitted samples.

There are significant differences between the two machines in terms of power source, mode of operation, application scenarios, etc. UTSTESTER summarises the following points for your analysis.

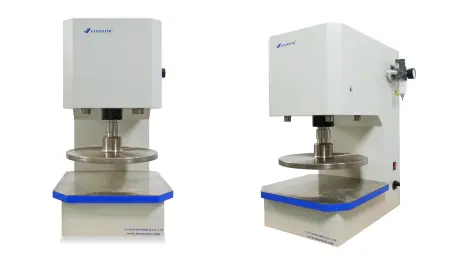

Hand pressure sample cutting machine by manually pressing the handle or pressure plate, drive the blade downward movement to complete the cutting. Using the leverage principle of energy-saving structure can easily cut fabrics, hand-controlled operation without electricity, because the volume is relatively lightweight, so even the less powerful women can operate the use of work efficiency steadily increased. Suitable for small batch and scattered sample production.

Pneumatic sample cutting machine is connected to the air source, and then the pneumatic device is controlled by foot switch or button to automatically cut with downward pressure. The cutting speed is fast and continuous operation can be realised, which is suitable for mass production. The pneumatic system provides stable pressure, short cutting time, and significantly higher productivity than the hand-pressure type. Pneumatic pressure is stable and uniform cutting strength, cutting pressure of 1000Kg, 2Ton, 5Ton can be selected, and can be customised with various sizes of cutting blade templates, which can achieve high-precision cutting with neat edges and small dimensional errors. Whether manual or electric sample cutting machine is to achieve a uniform cut neat and generous, cutting surface flat, uniform and coherent cut to avoid burrs, skewed, serrated inconsistent phenomenon.

Hand-pressure sample cutting machine manually operated controllable, the use of light or medium-thickness fabrics (such as cotton, linen, silk, ordinary chemical fibres), suitable for small-scale operators or the need to flexibly adjust the cutting position of the scene. The equipment is less expensive and has a simple structure.

Pneumatic sample cutters are suitable for a wide range of fabric thicknesses, including thick fabrics, leather, and composites (e.g., multi-layer waterproof fabrics).

Can cut multiple layers of fabric overlapping, suitable for industrialised mass production. Easy to operate, low physical strength requirement, novice can start after simple training.

Home

Home