0102030405

Application of sublimation fastness tester

2025-07-15

Sublimation fastness test apparatus, which is used to assess the stability of dyes in textiles at high temperatures, i.e. whether the dyes are released from the fibres and deposited on other materials when subjected to heat. This test is essential to ensure that textiles do not suffer from dye migration in everyday use, especially when high temperature treatment is required, such as ironing or dry cleaning.

Test Principle

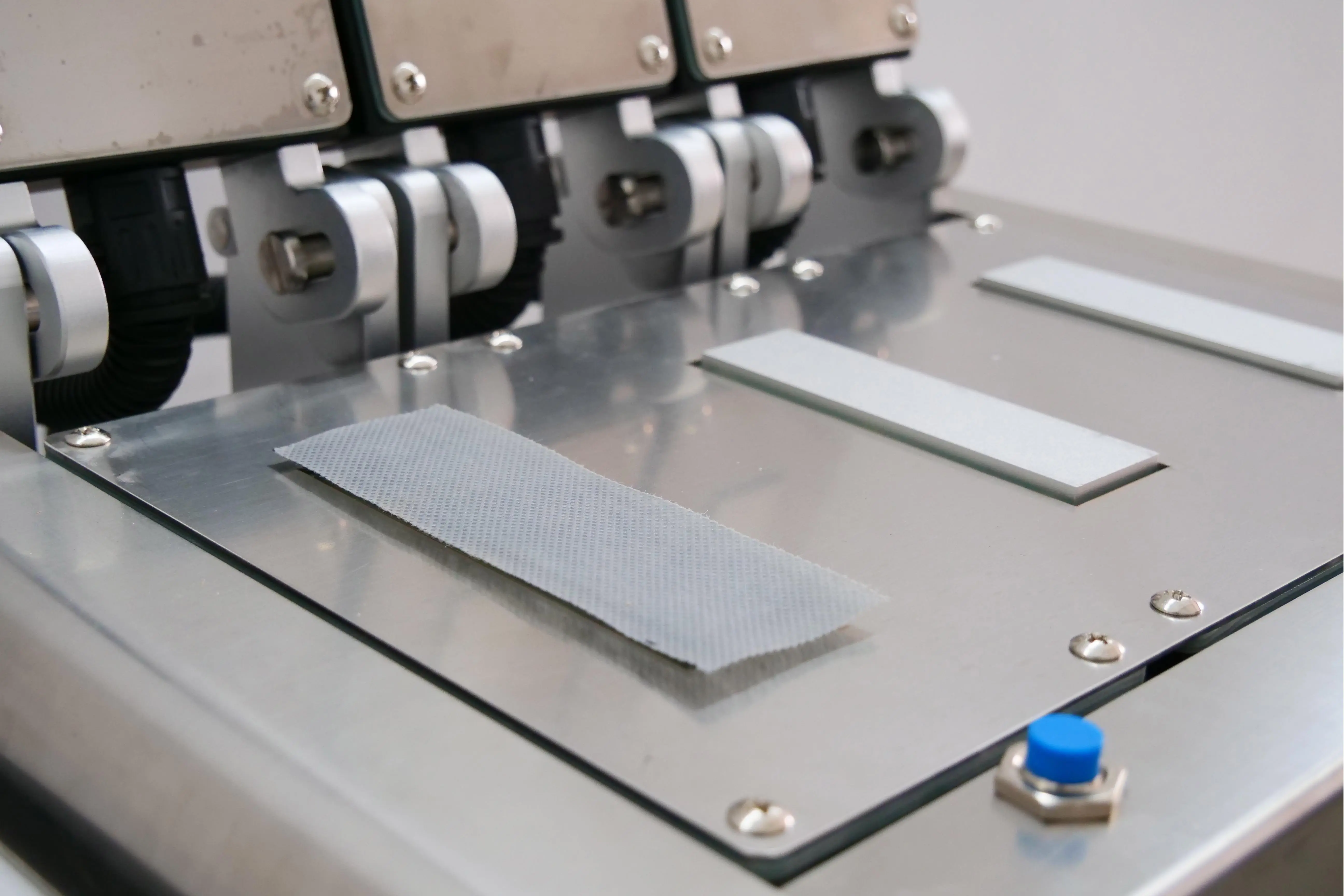

Sublimation fastness tests are usually carried out under laboratory conditions by simulating an actual high temperature environment, e.g. using dry heat pressing equipment. The specimen is treated at a specific temperature and then rubbed against a standard white cloth to check for dye transfer to the white cloth. The degree of transfer is assessed by comparing it with a standard colour card and is graded on a scale, usually from 1 to 5, with 5 indicating the best sublimation fastness.

Main Application Areas

Textile Manufacturing: Used to ensure that dyes do not come off easily and maintain colour stability of dyed fabrics after high temperature treatment.

Quality control: Sublimation fastness testing is an important part of quality control during the production process to ensure that the product meets standards.

Research and Development: In the research and development phase of new dyestuffs or textile processes, sublimation fastness testing can help to evaluate and improve the performance of materials.

Test Methods

Dry heat pressing: The specimen is placed on a hot plate at a specific temperature, usually 180°C, for a period of time and then rubbed.

Standard white cloth rubbing: The treated specimen is rubbed against a standard white cloth to check for dye transfer.

Rating Criteria: The sublimation fastness level is assessed according to the degree of dye transfer and compared with a standard colour card.

Features & Benefits

Accuracy: Highly accurate test equipment is used to ensure accurate results.

Automation: Modern Sublimation Fastness Testers are often equipped with automation features to simplify the operation process and improve efficiency.

Versatility: Different temperature and time parameters can be set to suit different types of textiles and dyes.

Precautions

When conducting the sublimation fastness test, care needs to be taken to keep the temperature and humidity of the laboratory environment stable to avoid external factors affecting the test results. Meanwhile, the operator should strictly follow the operation manual of the instrument to ensure safety and accuracy.

Sublimation fastness testing instruments are key tools in textile quality control and R&D, helping manufacturers and researchers to improve product performance and market competitiveness through the assessment of dye stability.

Home

Home