Home

Home

The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing advancements in textile technology, notably the Yarn Evenness Tester. As the global textile and apparel market is projected to reach a value of approximately USD 1.5 trillion by 2025, the demand for quality assurance tools has never been more critical.

Reports indicate that irregularities in yarn evenness can lead to substantial losses, estimated at 10-15% of production costs in the manufacturing process. By applying Yarn Evenness Tester technology, manufacturers can significantly enhance quality control, reduce waste, and ensure consistency in their products. This technological advancement not only complies with evolving industry standards but also aligns with a growing consumer demand for high-quality, sustainable textiles.

The fair will highlight how such innovations are essential for competitive advantage in the expansive textile sector.

The evolution of yarn evenness testing technology has significantly transformed the textile industry, enhancing quality control and ensuring consistent product standards. Traditionally, yarn testing relied on manual methods that were often subjective and prone to human error. However, advancements in technology have introduced sophisticated instruments capable of providing precise measurements of yarn evenness.

These innovations not only improve accuracy but also streamline the testing process, reducing the time and labor involved in quality assurance.

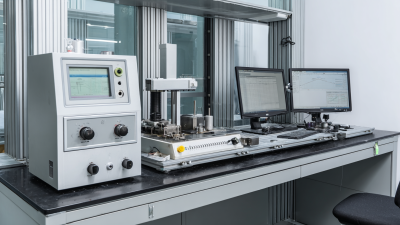

At the upcoming 138th China Import and Export Fair 2025, the latest developments in yarn evenness testers will be showcased, reflecting the industry's commitment to integrating cutting-edge technology into production practices. New testing devices utilize laser and optical sensors to rapidly analyze yarn characteristics, allowing manufacturers to detect imperfections early in the production line. This proactive approach enhances product quality and minimizes waste, directly benefiting both manufacturers and consumers in an increasingly competitive market. As the textile industry continues to evolve, the integration of advanced testing technologies will play a crucial role in maintaining high standards and fostering innovation.

At the 138th China Import and Export Fair, the advances in yarn evenness tester technology have garnered significant attention from industry professionals. These innovations are crucial for ensuring high-quality yarn production, which directly impacts the overall textile quality. The latest testers utilize advanced sensors and algorithms to provide real-time data on the evenness of yarn, allowing manufacturers to make timely adjustments during production. This leads to decreased waste and enhanced efficiency, ultimately benefiting the bottom line.

Tip: When evaluating yarn evenness testers, consider models that offer integrated software solutions for data analysis, as this can streamline process optimization and improve quality control.

Moreover, the fair featured demonstrations of the new testers in action, showcasing their precision and reliability. These devices now come equipped with user-friendly interfaces and connectivity options, making it easier for manufacturers to implement them in their workflows. Visitors were particularly impressed with features like predictive analytics, which not only assess current production runs but also anticipate potential issues before they arise.

Tip: It's beneficial to engage with suppliers directly at trade shows to gain insights into their technology's support services and training programs, ensuring you maximize your investment in new testing equipment.

| Tester Model | Measurement Range (Cv %) | Accuracy | Data Output | Features |

|---|---|---|---|---|

| Model A | 0.5 - 10.0 | ±0.1% | USB, Print | Real-time monitoring, Data logging |

| Model B | 0.1 - 5.0 | ±0.05% | Wireless, Cloud | Automated alerts, Remote access |

| Model C | 0.2 - 8.0 | ±0.1% | HDMI, Print | User-friendly interface, High-resolution display |

| Model D | 0.5 - 15.0 | ±0.2% | Ethernet, Print | Multi-language support, Robust design |

The role of yarn evenness testers in enhancing fabric quality and production efficiency cannot be overstated, especially in the highly competitive textile industry. As reported by the International Textile Manufacturers Federation (ITMF), uneven yarn can lead to significant defects in fabric, potentially affecting up to 30% of production output. By employing advanced yarn evenness testing technology, manufacturers are able to ensure a consistent yarn diameter, which translates directly into improved fabric quality and reduced waste.

One of the standout features of modern yarn evenness testers is their ability to provide real-time data analysis, allowing manufacturers to swiftly identify and rectify issues in the spinning process. This not only optimizes production efficiency but also helps in maintaining high-quality standards, which are crucial for meeting consumer demands. According to a recent report by the Textile Industry Association, implementing such testing technology has been linked to a 15% increase in overall productivity.

Tips: When selecting a yarn evenness tester, consider models that offer integrated data analytics for more efficient monitoring. Regular calibration and maintenance of the testing equipment can further enhance accuracy and prolong its lifespan, ensuring you get the best results from your investment.

The demand for high-quality yarn continues to surge in the textile manufacturing industry, driven by evolving consumer preferences and technological advancements. Notably, the global polyester yarn market is projected to witness a growth from $71.18 billion in 2024 to $117.01 billion by 2033, at a robust CAGR of 5.7%. This increasing demand reflects a broader trend towards sustainable and eco-friendly materials, as consumers increasingly prioritize quality and sustainability in their textile products.

In the backdrop of this evolving market landscape, innovations such as Yarn Evenness Tester Technology can significantly enhance production quality. By ensuring uniformity in yarn, manufacturers can minimize defects, reduce waste, and ultimately deliver superior products that meet consumer expectations.

**Tip:** As a textile manufacturer, investing in advanced testing technologies can play a crucial role in maintaining competitive edge in a market that favors quality.

Furthermore, segments like eco-friendly fibers are gaining traction, with the global market expected to rise from $56.81 billion in 2023 to $120.99 billion by 2032, reflecting a CAGR of 8.8%. This shift not only presents growth opportunities but also emphasizes the necessity for manufacturers to adapt to these changing trends to capture a larger market share.

**Tip:** Adopting eco-friendly practices and materials can enhance brand reputation and attract environmentally conscious consumers.

The 138th China Import and Export Fair in 2025 highlights the transformative role of yarn evenness tester technology in the textile industry. Leading Chinese textile companies have successfully implemented this technology, showcasing significant improvements in production efficiency and product quality. By utilizing advanced testing machines, these companies can accurately assess yarn consistency, which is crucial for maintaining high standards in fabric production.

One notable case is a prominent textile manufacturer that integrated yarn evenness testers into their quality control processes. By adopting this technology, they reported a 30% reduction in defect rates, which led to increased customer satisfaction and reduced waste. Another example includes a high-end fabric producer that leveraged real-time data from these testers to enhance their supply chain management, resulting in faster response times to market demands. These case studies illustrate how embracing innovative testing solutions not only optimizes manufacturing processes but also elevates the overall competitiveness of enterprises in the global textile market.