Home

Home

In the packaging industry, the ability to effectively measure the permeability of materials to water vapor is critical for ensuring product integrity and longevity. A Water Vapor Transmission Tester plays a pivotal role in this process, providing manufacturers with the tools needed to assess how well their packaging can protect contents from moisture. Understanding the principles and methodologies behind water vapor transmission testing is essential for selecting the right materials and optimizing packaging designs. This article delves into the fundamental concepts of water vapor transmission, explores the significance of testing in various applications, and offers practical insights for using a Water Vapor Transmission Tester effectively. By gaining a comprehensive understanding of these aspects, packaging professionals can make informed decisions that enhance product quality and customer satisfaction.

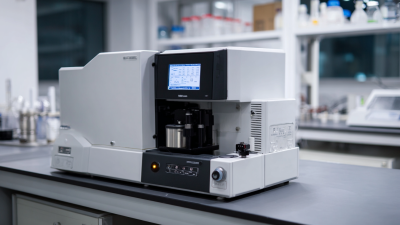

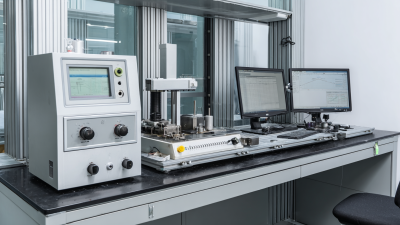

When it comes to evaluating packaging materials, understanding the water vapor transmission rate (WVTR) is crucial. Various measurement techniques are employed to assess how well materials resist moisture permeation, significantly impacting the shelf life of products. Among the most common techniques are the gravimetric, infrared, and electrical methods. The gravimetric method, for example, measures the weight change of a sample over time and is often considered a standard for its accuracy. According to a report from the Packaging Technology and Science journal, materials with a WVTR below 0.1 g/m²/day are ideal for sensitive goods, ensuring minimal moisture ingress.

In addition to these traditional methods, more advanced techniques like differential scanning calorimetry (DSC) and thermal gravimetric analysis (TGA) are gaining traction. These methods provide insights into the material's behavior under different temperature conditions and moisture levels. As per a recent study published in the Journal of Food Science, advanced methodologies can reveal critical data about polymer morphology and its influence on barrier properties.

**Tips:** For manufacturers, regularly updating testing protocols to include multiple WVTR methods can enhance the reliability of packaging solutions. Additionally, consider the end product's storage conditions when selecting materials, as environmental factors can significantly alter moisture absorption rates.

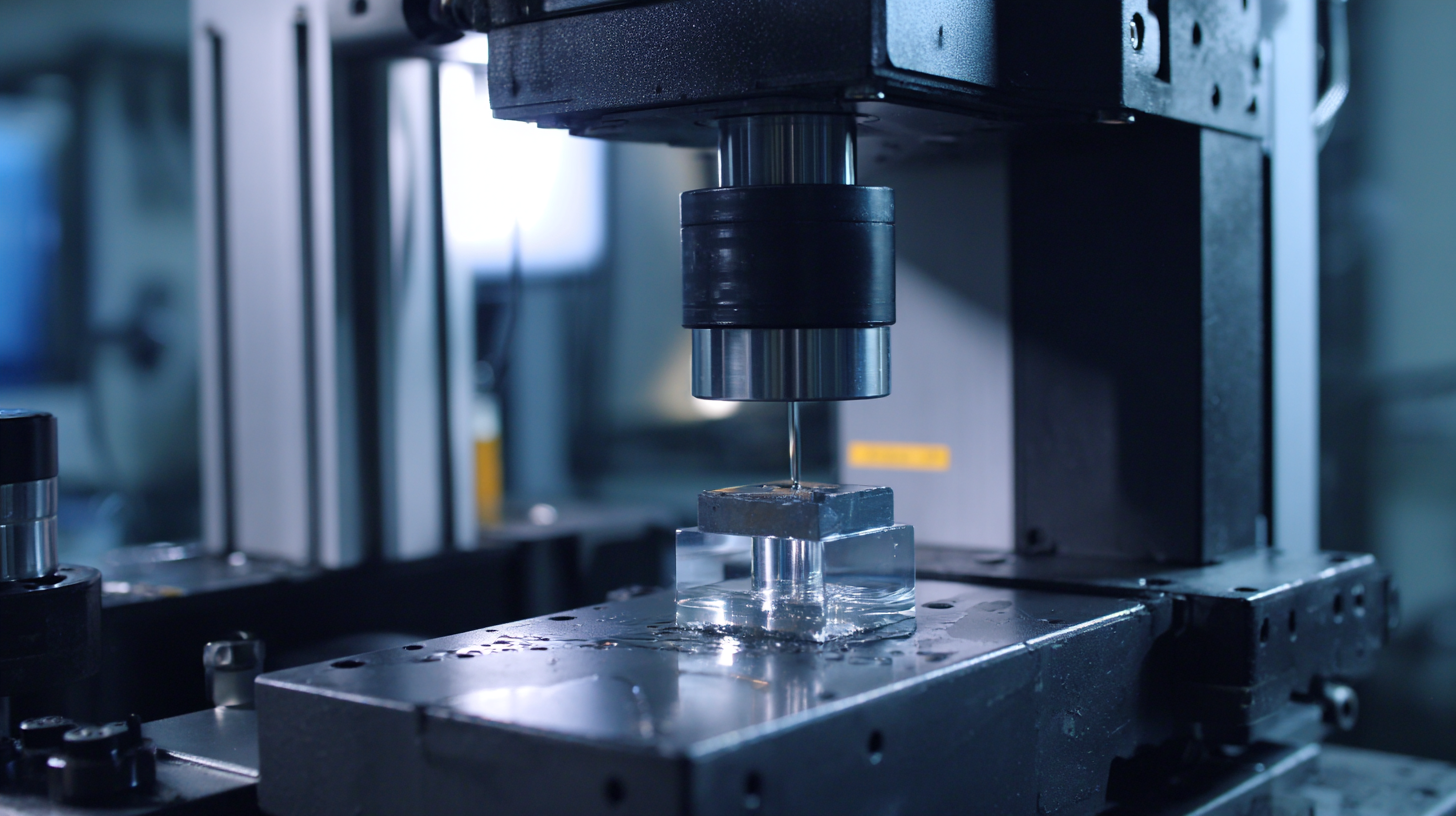

Water vapor transmission rates (WVTR) play a crucial role in determining the efficacy of packaging materials. Various factors influence these rates, including the intrinsic properties of the materials, external environmental conditions, and the methods used in manufacturing. For instance, materials that are inherently hydrophobic tend to exhibit lower WVTR, making them more effective at preventing moisture ingress. Additionally, the thickness and surface characteristics of the packaging can significantly affect how water vapor permeates through.

Recent advancements in barrier technologies have led to the development of films that exhibit exceptional resistance to water vapor, comparable to glass. Innovative techniques such as printing and UV irradiation have been employed to create these advanced barriers, which are being utilized not only in snack packaging but also in applications like solar cells. While traditional vacuum deposition methods have provided high barrier performance, they face challenges related to production efficiency and costs. Understanding these influencing factors and the evolution of barrier technologies is essential for optimizing packaging solutions that protect products from moisture while remaining economically viable.

Water vapor transmission testing is a critical aspect of evaluating the barrier properties of packaging materials. Standard methods employed in this testing vary significantly, providing insights into the effectiveness of different materials under specific conditions. Commonly used standards include ASTM E96 and ISO 15106, which offer methodologies for measuring the permeability of materials to water vapor. These tests help manufacturers determine the suitability of packaging for various products, especially those sensitive to moisture.

The comparison of these standard methods reveals nuances that can affect results. For instance, ASTM E96 employs both a cup method and a dish method, allowing for flexibility depending on the material type, while ISO 15106 focuses on films and sheets, emphasizing a controlled environment that could lead to more precise results. Understanding these differences is vital for manufacturers seeking to optimize their packaging solutions, as the choice of testing method can influence the perceived barrier performance and, ultimately, the quality of the packaged product. Making informed decisions based on thorough testing comparisons ensures better protection against moisture, extending the shelf life and maintaining the integrity of the packaged goods.

| Testing Method | Test Environment | Measurement Unit | Typical WVT Rate (g/m²/day) | Applications |

|---|---|---|---|---|

| Desiccant Method | 23°C / 50% RH | g/m²/day | 0.1 - 10.0 | Flexible Packaging |

| Cup Method | 23°C / 50% RH | g/m²/day | 0.2 - 5.0 | Food Packaging |

| EIA Method | 38°C / 90% RH | g/m²/day | 0.05 - 3.0 | Pharmaceuticals |

| ASTM F1249 | 23°C / 85% RH | g/m²/day | 0.1 - 2.5 | Industrial Applications |

Water vapor transmission testing is a critical process in evaluating packaging materials, especially in the food industry. This testing measures the rate at which moisture permeates through packaging, helping manufacturers determine how well their products can protect food items from spoilage and degradation caused by humidity. Efficient packaging not only extends the shelf life of food products but also maintains their quality, flavor, and nutritional value. Therefore, understanding water vapor transmission rates is essential for selecting appropriate materials that meet specific product requirements.

The implications of these tests go beyond mere packaging selection. For instance, they influence the design of packaging systems tailored to different food types, ensuring that goods are stored under optimal conditions during transportation and shelf life. Additionally, as consumer demand for fresher, preservative-free options grows, food manufacturers are increasingly turning to advanced packaging materials that offer better moisture barriers. Ultimately, effective water vapor transmission testing not only aids in protecting food quality but also complies with regulatory standards, supporting the industry's commitment to safety and sustainability.

Selecting the right packaging materials is a critical decision for ensuring product longevity and quality. Water Vapor Transmission Rate (WVTR) is an essential factor that provides insights into how much moisture can penetrate packaging, potentially affecting the contents. According to a recent report by the Flexible Packaging Association, materials with a low WVTR are ideal for products sensitive to moisture, such as snacks and pharmaceuticals. Understanding the specific WVTR requirements for different products can significantly influence shelf life and consumer satisfaction.

Tips: When evaluating packaging materials, prioritize those that fit your product's moisture sensitivity. For delicate items such as electronics and food, opting for multilayer laminates can provide superior moisture barriers, minimizing the risk of spoilage. Additionally, utilize ASTM F1249 for standardized WVTR testing to ensure the reliability of the data.

It's also essential to stay updated with the latest industry trends and testing methodologies. For instance, packaging materials with a WVTR of less than 0.1 g/m²/day are considered exceptional for high-stability products, as noted in the latest market analysis by Packaging Strategies. By leveraging this data, businesses can make informed decisions that align with their product protection needs while maintaining cost-effectiveness.

Tips: Collaborate with suppliers who provide comprehensive WVTR data and can guide you in selecting the most sustainable and effective packaging solutions tailored to your specific products.