Home

Home

In the world of creative audio production, the "Wrap Reel Electronic" is an essential tool. Industry expert Daniel Harris emphasizes its importance by saying, “Mastering the wrap reel can elevate your sound projects remarkably.” Yet, many users fail to maximize its potential.

Using the Wrap Reel Electronic effectively requires careful attention. Beginners often overlook key settings, resulting in subpar sound quality. Each reel's tension affects audio fidelity. Users need to experiment with different settings to find their unique sound.

Mistakes can happen, like improper threading that leads to tangled reels. This not only frustrates users but may also compromise the project's integrity. Reflection on these missteps can lead to improved techniques in future projects. Embracing these challenges is part of mastering the Wrap Reel Electronic. Each lesson learned contributes to greater expertise and creativity.

A wrap reel electronic is designed to simplify your work. Understanding its components is essential for proper use. The main parts include

the motor,

reels, and

control panel. Familiarize yourself with each element. This makes operating easier.

Begin by selecting the right size reel for your project. Incorrect sizes can lead to frustrating complications.

Check the connections; loose cables may cause malfunctions. If you notice hesitation, pause and examine the setup. Even a minor misalignment can hinder performance.

Experimentation is key. Test the wrap reel in different scenarios. Take mental notes on what works and what doesn’t.

Some users struggle with speed settings. Adjusting the speed too quickly can lead to uneven wrapping. Remember, practice makes perfect. You might not achieve flawless results immediately, but

learning from mistakes is vital.

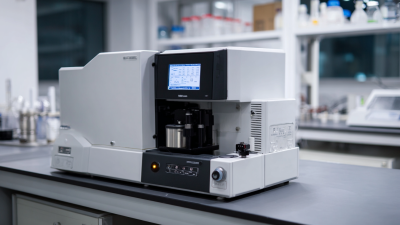

When using a wrap reel electronic, understanding its key components is essential. The main parts include the reel itself, the motor, and the control panel. The reel stores the material you want to wrap. It’s crucial that this part is strong and durable. If not, wear and tear can lead to frustration. The motor drives the reel's rotation and must work smoothly. A malfunctioning motor can halt the process unexpectedly.

The control panel allows you to adjust settings. It’s important to familiarize yourself with these settings. If you make a mistake, it might affect your output. Experiment with different configurations to see what works best. Sometimes, the simplest adjustments can lead to significant improvements. Don't ignore the importance of regular maintenance. Neglecting this can lead to performance issues over time.

Take note of the wrap tension as well. Too tight, and you might damage the material. Too loose, and you could ruin the wrapping quality. Monitoring this requires practice and attentiveness. Each project may present new challenges. Reflection on past experiences can guide better decision-making in future tasks. Learning is an ongoing journey in mastering the use of a wrap reel electronic.

Setting up a wrap reel electronic can seem daunting, but with the right steps, it becomes manageable. Begin by ensuring that your workspace is clear and organized. Gather necessary tools, like a screwdriver and a measuring tape. According to a report by the Packaging Association, nearly 65% of businesses face operational delays due to improper setup. This step is crucial to avoiding any unnecessary interruptions.

Next, follow the manufacturer’s instructions carefully. Each wrap reel varies slightly. Take the time to measure the distance from the reel to the application point. Professional studies indicate that accurate measurements can improve efficiency by up to 30%. Mistakes in this stage can lead to wrap waste, which is both costly and environmentally damaging.

Finally, once set up, test the system with a few rolls. Monitor for any issues. Reflect on what works and what could improve. Data from industry leaders suggest that regular adjustments can enhance performance over time. It’s important to recognize that each installation holds room for growth. Embrace those imperfections, as they offer valuable learning experiences.

| Step | Action | Description | Tips |

|---|---|---|---|

| 1 | Unboxing | Carefully remove the wrap reel from the packaging. | Check for any damages during shipping. |

| 2 | Assembly | Connect any necessary components following the manual. | Ensure all parts are tightly secured. |

| 3 | Calibration | Calibrate the reel according to the settings specified. | Take your time to ensure accuracy. |

| 4 | Testing | Run a test to ensure everything is functioning properly. | Address any issues before full use. |

| 5 | Operation | Begin normal operation according to your needs. | Follow best practices for safety and efficiency. |

Using a wrap reel electronic effectively requires a mix of technique and careful planning. Start by positioning the reel in a stable area. This prevents any unnecessary wobbling while you work. Pay attention to the direction of the wrap. It’s essential to maintain consistency to avoid tangles.

When wrapping, use a slow and steady pace. Rushing can lead to uneven coils. Additionally, practice makes perfect. Spend time familiarizing yourself with the device. Mark any common mistakes, like over-wrapping or under-wrapping. This reflection helps improve your technique over time.

As you gain experience, challenge yourself with more complex wraps. Take notes on what works best for you. It's okay to feel unsure at times. Each attempt is a learning opportunity. Incorporate feedback from peers, if available, to adjust your approach. Keep testing and refining your methods for the best results.

Maintaining your wrap reel electronics is crucial for optimal performance. Regular upkeep can prevent breakdowns and ensure longevity. Focus on cleaning, checking components, and addressing issues promptly.

One essential tip is to keep the reel clean. Dust, dirt, and debris can interfere with the electronic parts. Use a soft cloth to wipe down surfaces. Don't forget to check for any buildup in hard-to-reach areas. A clean wrap reel will perform better and last longer.

Another important aspect is to inspect connections regularly. Loose wires can lead to poor performance. Securely fasten all cables and connectors. If any component looks worn, consider replacing it sooner rather than later. Proactive care can save time and money in the long run.

Lastly, store your wrap reel in a dry environment. Moisture can damage electronics over time. Ensure it’s in a stable, cool area. Regular maintenance is not just about fixing what's broken. It's about preventing issues before they arise.