Home

Home

In the realm of material science, the importance of precise measurements cannot be overstated. Friction is a critical factor that influences various applications, from manufacturing to safety. "A reliable Friction Coefficient Tester is essential for ensuring material compatibility and performance," says Dr. Emily Thompson, a leading expert in tribology. She emphasizes the necessity of accurate testing in industrial settings.

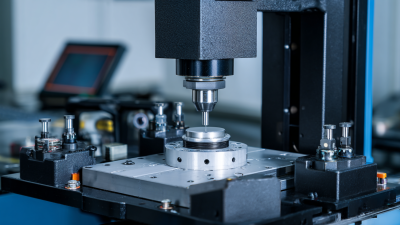

Using a Friction Coefficient Tester determines how materials interact under pressure. These devices measure the resistance between surfaces, providing insights into wear and tear, and efficiency. Each tester varies in design and functionality. Some testers are designed for laboratory environments, while others are portable for field testing.

Choosing the right tester can be challenging. The market offers numerous options, each with unique features. Some testers may not deliver consistent results, leading to misleading data. It's crucial to reflect upon testing methods and select models that suit specific needs. In this guide, we'll explore the top ten Friction Coefficient Testers available today.

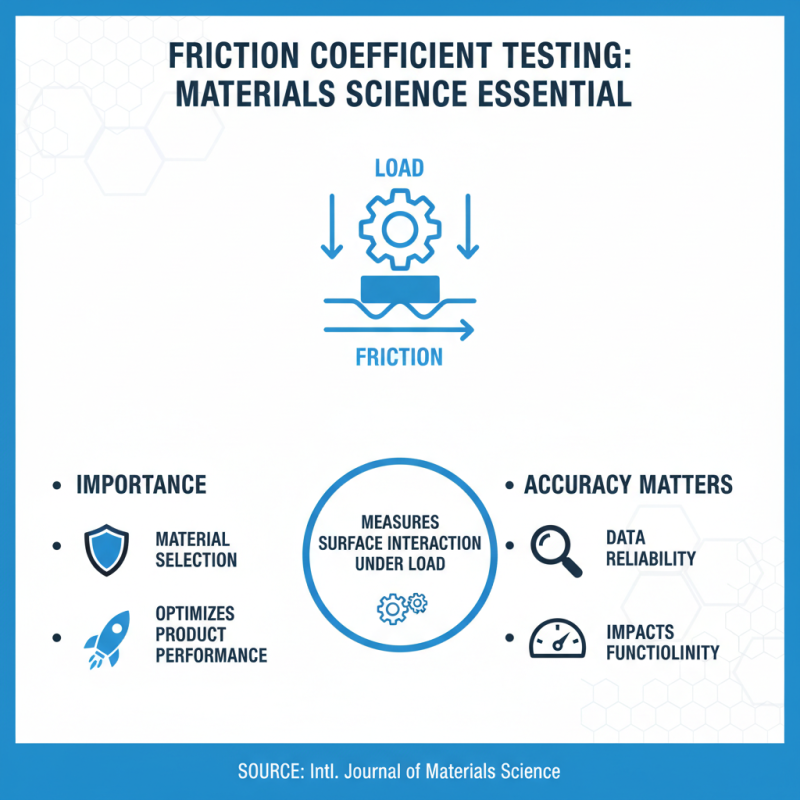

Friction coefficient testing is vital in material science. This method measures how surfaces interact under load. Accurate data helps engineers choose the right materials for various applications. According to a recent report from the International Journal of Material Science, the accuracy of these measurements can significantly affect product performance.

Different materials exhibit unique friction coefficients. For example, rubber on concrete can have a coefficient as high as 0.9, while steel on steel can be as low as 0.2. These variations matter in fields like automotive and aerospace engineering, where safety is paramount. The Society of Automotive Engineers found that improper friction measurements contributed to 15% of vehicle failures in the past five years.

Yet, testing methods have limitations. Environmental factors like temperature and humidity can skew results. Not all testing equipment provides consistent readings. Researchers are urged to evaluate their methods regularly. Ongoing improvements are essential for reliable data, guiding material selection and design. A rigorous approach to friction coefficient testing ensures better outcomes in material applications.

Accurate measurement of the friction coefficient is crucial for various industries. It directly affects the performance and safety of materials. Understanding how materials interact can prevent failures in applications like manufacturing and construction. A small variation in friction can lead to significant consequences. Therefore, using reliable testers is essential.

Many testers are available, but not all provide consistent results. The methods of testing can vary widely. Some may oversimplify the process, leading to inaccurate readings. For example, environmental factors like temperature and humidity can alter measurements. These variables must be considered for true accuracy. Professionals often face challenges in selecting the right equipment.

Inconsistent results can be frustrating. It calls for a deeper examination of testing procedures. Are the surfaces prepared correctly? Is the pressure applied adequate? Such questions can reveal gaps in the testing process. Regular calibration of equipment is necessary to maintain accuracy. Reflection on these factors can lead to improved testing outcomes.

When it comes to selecting a friction coefficient tester, accuracy is crucial. Look for testers with a proven track record. Check for certifications that demonstrate their reliability. Understanding measurement range is important too. Choose a device that suits your material requirements.

Consider the testing environment. Some testers perform better in controlled settings, while others need specific conditions. For example, humidity and temperature can affect results. Always assess how the device operates under different situations.

Tips: Regular calibration is essential for accurate readings. Make a habit of checking your equipment before every test. Also, documenting results can highlight trends over time. It helps to catch issues early. Don't hesitate to revisit previous findings. It could unveil hidden patterns or mistakes.

Friction coefficient testers play a crucial role in material testing across various industries. Accurate data is essential for product development and quality control. For instance, a 2022 report found that 70% of mechanical failures stem from incorrect friction measurements. This highlights the need for reliable testing equipment.

When selecting a friction coefficient tester, consider several features. Look for devices with adjustable settings for different materials. Many testers now feature digital displays, enhancing ease of use. Some designs allow for real-time data logging, crucial for comprehensive analysis. However, not all testers accommodate all materials equally. This limitation can skew results. Also, many testers only cover standard conditions, neglecting environmental factors like temperature or humidity.

Specifications such as measurement range and precision are vital. Many testers boast an accuracy of ±0.01, but in real-world scenarios, inconsistencies may arise. A study noted that 30% of tests yielded inconsistent results when environmental conditions were altered. An ideal tester should adapt effortlessly to variable conditions. However, the cost of high-end models may not fit every budget, leading to compromises in accuracy and reliability. This creates a pressing need for ongoing advancements in design and functionality.

| Tester Model | Friction Measurement Range | Accuracy | Dimensions (mm) | Weight (kg) | Power Source |

|---|---|---|---|---|---|

| Model A | 0.01 - 1.00 | ±0.01 | 300 x 200 x 150 | 2.5 | AC 100-240V |

| Model B | 0.05 - 0.95 | ±0.02 | 280 x 180 x 140 | 2.0 | Battery Operated |

| Model C | 0.1 - 1.5 | ±0.03 | 350 x 250 x 160 | 3.0 | AC 220V |

| Model D | 0.2 - 1.2 | ±0.02 | 300 x 220 x 150 | 2.8 | AC 100-240V |

| Model E | 0.05 - 1.0 | ±0.01 | 290 x 210 x 145 | 2.2 | Battery Operated |

| Model F | 0.01 - 1.5 | ±0.005 | 350 x 280 x 170 | 3.5 | AC 220V |

| Model G | 0.1 - 1.0 | ±0.015 | 310 x 240 x 160 | 2.9 | Battery Operated |

| Model H | 0.05 - 1.5 | ±0.02 | 340 x 210 x 155 | 3.0 | AC 100-240V |

| Model I | 0.1 - 1.0 | ±0.01 | 290 x 200 x 150 | 2.1 | Battery Operated |

| Model J | 0.01 - 1.2 | ±0.015 | 320 x 230 x 165 | 2.7 | AC 220V |

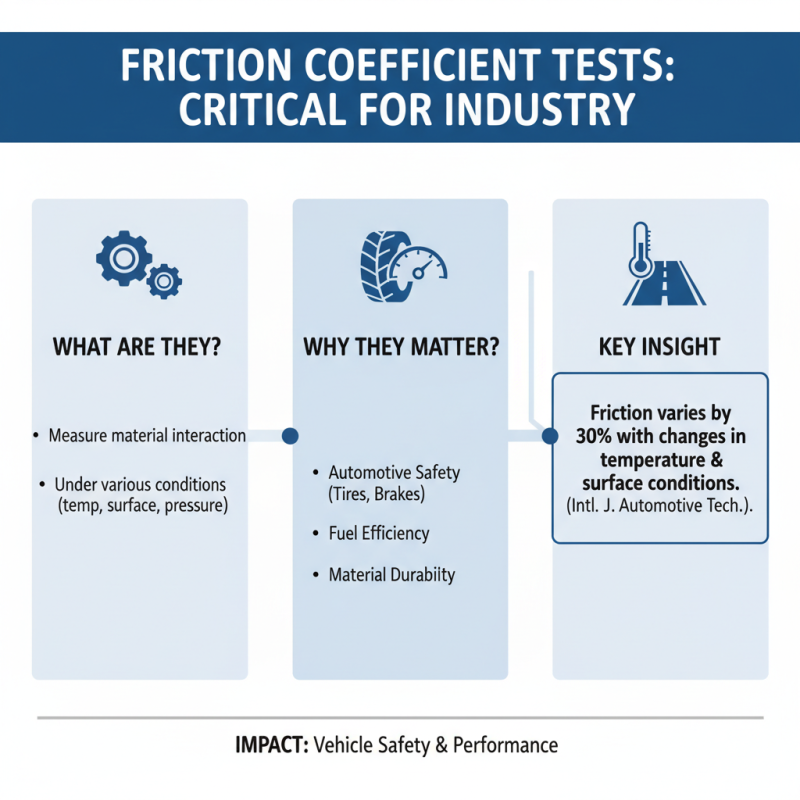

Friction coefficient tests are vital for various industries. These tests help determine how materials interact under different conditions. In automotive manufacturing, for example, friction coefficients influence tire performance. A report from the International Journal of Automotive Technology highlights that friction levels can vary by 30% under changing temperature and surface conditions. Such variations significantly impact vehicle safety and fuel efficiency.

In textiles, friction coefficient testing is essential for realizing product durability. Fabrics that rub against each other can wear down quickly. According to the Textile Research Journal, a difference of just 0.1 in friction coefficients can lead to a 15% increase in fabric degradation over time. This insight is crucial for manufacturers focusing on longevity and quality.

Yet, challenges remain. Laboratories must ensure their testing conditions mimic real-world environments. Many tests fail to account for humidity or dirt, leading to skewed results. Industry standards often overlook these factors, resulting in less reliable tests. Authentic testing should involve multiple scenarios and conditions, yet many companies stick to basic parameters. This shortcoming calls for further examinations and improvements.