Home

Home

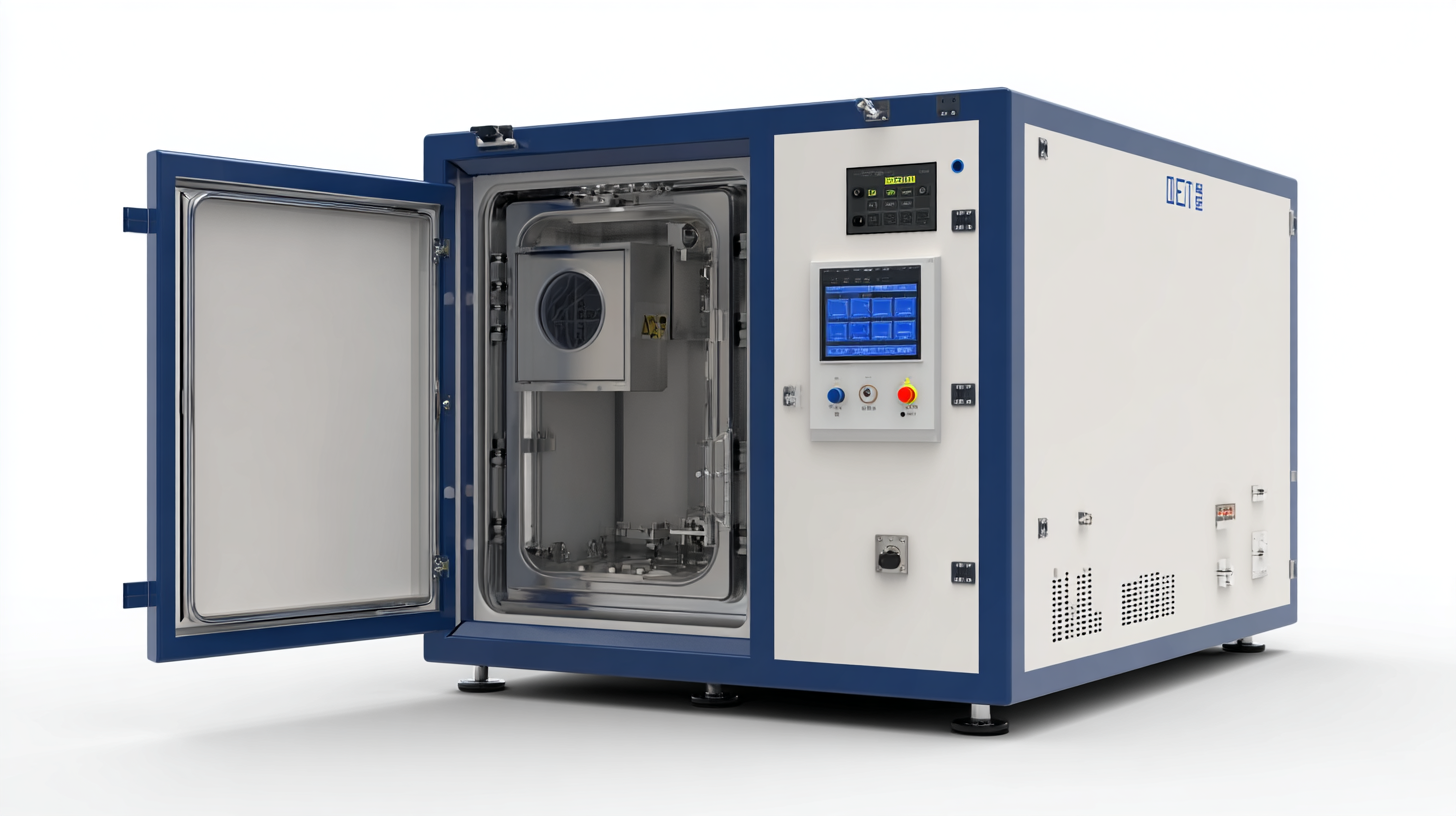

In today's fast-paced and competitive market, ensuring the reliability and durability of products is paramount for manufacturers across various industries. One of the most effective ways to achieve this is through the use of advanced climate control technologies, specifically Temperature and Humidity Test Chambers. These sophisticated environments allow researchers and engineers to simulate extreme conditions, helping to predict how products will perform under real-world scenarios. By maintaining precise temperature and humidity levels, these test chambers enable thorough evaluation of materials, components, and finished goods, helping to identify potential weaknesses and improve overall quality.

Understanding the significance of temperature and humidity testing is crucial for organizations looking to enhance product development and customer satisfaction. The insights gained from these tests not only contribute to compliance with industry standards but also foster innovation and reduce the risk of product failure in the field. As we explore the top 5 Temperature and Humidity Test Chambers available on the market, we will delve into their features, benefits, and applications, highlighting how these essential tools can support manufacturers in delivering reliable, high-quality products tailored to meet consumer demands.

When evaluating temperature and humidity test chambers, several key features are essential for ensuring precise and reliable product testing. Firstly, temperature control range is critical; look for chambers that support a wide temperature span to mimic different environmental conditions. Additionally, humidity control is just as vital; chambers should offer a relative humidity range suitable for your specific testing requirements, allowing you to assess how products behave under varying moisture levels.

Another important feature is the chamber's stability and uniformity. A reliable test chamber must maintain consistent temperature and humidity levels throughout the testing area to avoid skewed results. Furthermore, advanced control systems and data logging capabilities enhance the usability of these chambers, enabling accurate tracking of environmental changes and facilitating easier analysis of test results.

Tips: When selecting a temperature and humidity test chamber, consider opting for a model with easy-to-use software interfaces for monitoring and controlling the chamber conditions. Regular maintenance and calibration of the chambers will ensure longevity and accuracy in testing. Additionally, always review the manufacturer's specifications and seek chambers that comply with industry standards to guarantee reliability in your testing processes.

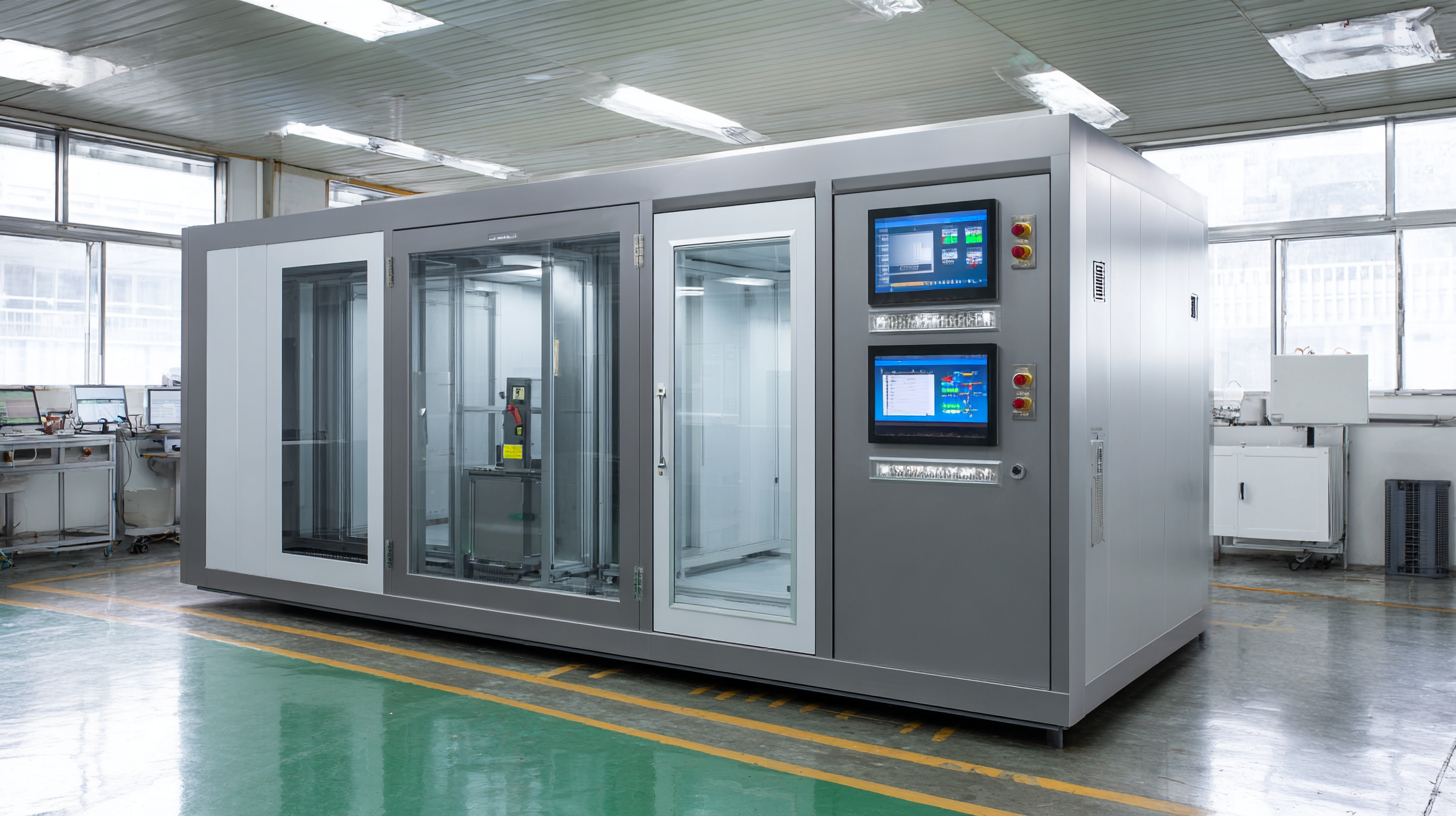

Effective climate control is paramount in product development, ensuring reliability and performance in varied environmental conditions. The global climate chamber market is projected to grow from $891 million in 2025 to $737 million by 2033, showcasing a stable compound annual growth rate (CAGR) of 2.4%. This growth underscores the increasing importance of advanced climate control solutions in enhancing product endurance against temperature and humidity fluctuations.

Incorporating rigorous testing in climate chambers allows manufacturers to simulate extreme conditions, which is crucial for identifying potential failures before product release. Industries ranging from automotive to electronics leverage these chambers for comprehensive testing, reducing the risk of costly recalls and boosting consumer confidence.

**Tips:** When selecting a temperature and humidity test chamber, consider the chamber’s capacity to replicate real-world environmental conditions specific to your product. Additionally, prioritize features like real-time monitoring and data logging to enhance your testing efficiency. Regular maintenance of these chambers is essential to ensure they deliver accurate and reliable results over time.

When selecting the right temperature and humidity test chamber for your specific needs, it’s essential to consider several key factors. First and foremost, assess the range of temperatures and humidity levels you require for your tests. Different chambers are designed for varying ranges, so knowing your specific testing parameters can help narrow down your options. Look for a chamber with precise control mechanisms that offer stable conditions throughout the testing process. This accuracy is crucial for reliable results, especially in industries such as pharmaceuticals and electronics where product quality is paramount.

Another important factor is the size and capacity of the test chamber. Consider the dimensions of the items you will be testing and ensure that the chamber can accommodate them comfortably without compromising the environmental conditions. Additionally, evaluate the chamber's ease of use, including its user interface and data logging capabilities. Advanced features like programmable settings and remote monitoring can enhance your testing experience, allowing for more efficient operation and better data collection. By carefully weighing these aspects, you can make an informed decision that meets both your technical requirements and operational needs.

Maintaining optimal performance in temperature and humidity test chambers is critical for ensuring product reliability across various industries. First and foremost, regular calibration of the chamber's control systems and sensors is essential. This process guarantees that temperature and humidity readings are accurate, allowing for consistent environmental conditions during testing. Implementing a routine maintenance schedule helps to identify and address any potential issues before they impact performance, ensuring that the chamber operates within its specified parameters.

In addition to calibration, proper management of the test sample environment plays a significant role in achieving reliable results. Users should ensure that products are appropriately placed within the chamber to allow for uniform exposure to temperature and humidity fluctuations. Utilizing racks or holders can optimize air circulation, preventing hot or cold spots that could skew test outcomes. Moreover, monitoring the chamber's door usage is vital; minimizing the frequency and duration of door openings reduces the risk of temperature and humidity fluctuations, thus fostering a more stable testing environment. By prioritizing these best practices, companies can enhance the functionality and reliability of their test chambers, leading to more accurate and trustworthy product evaluations.

In the realm of product testing, temperature and humidity test chambers play a pivotal role in ensuring reliability and performance. A comparative analysis of the top five brands in this technology reveals significant advancements that cater to diverse industry needs. Leading manufacturers now integrate sophisticated climate control systems that allow for precise adjustments, enabling rigorous testing conditions that mimic real-world environments. This capability is crucial for industries such as electronics, pharmaceuticals, and automotive, where product failure can result in substantial financial and reputational losses.

Each brand brings unique features to the table, including enhanced automation, user-friendly interfaces, and innovative data logging options. For instance, some chambers offer expanded temperature ranges and humidity control, ensuring thorough testing of materials and components. Others emphasize energy efficiency and sustainability, reducing operational costs while maintaining high performance standards. When choosing the right testing chamber, it's essential to consider these features in relation to specific testing requirements, helping organizations achieve optimal outcomes in product development and quality assurance.

This chart illustrates the performance of various temperature and humidity test chambers based on key metrics such as temperature range, humidity control, volume capacity, power consumption, and noise level. The data showcases the capabilities of the technology in ensuring product reliability through advanced climate control.