Home

Home

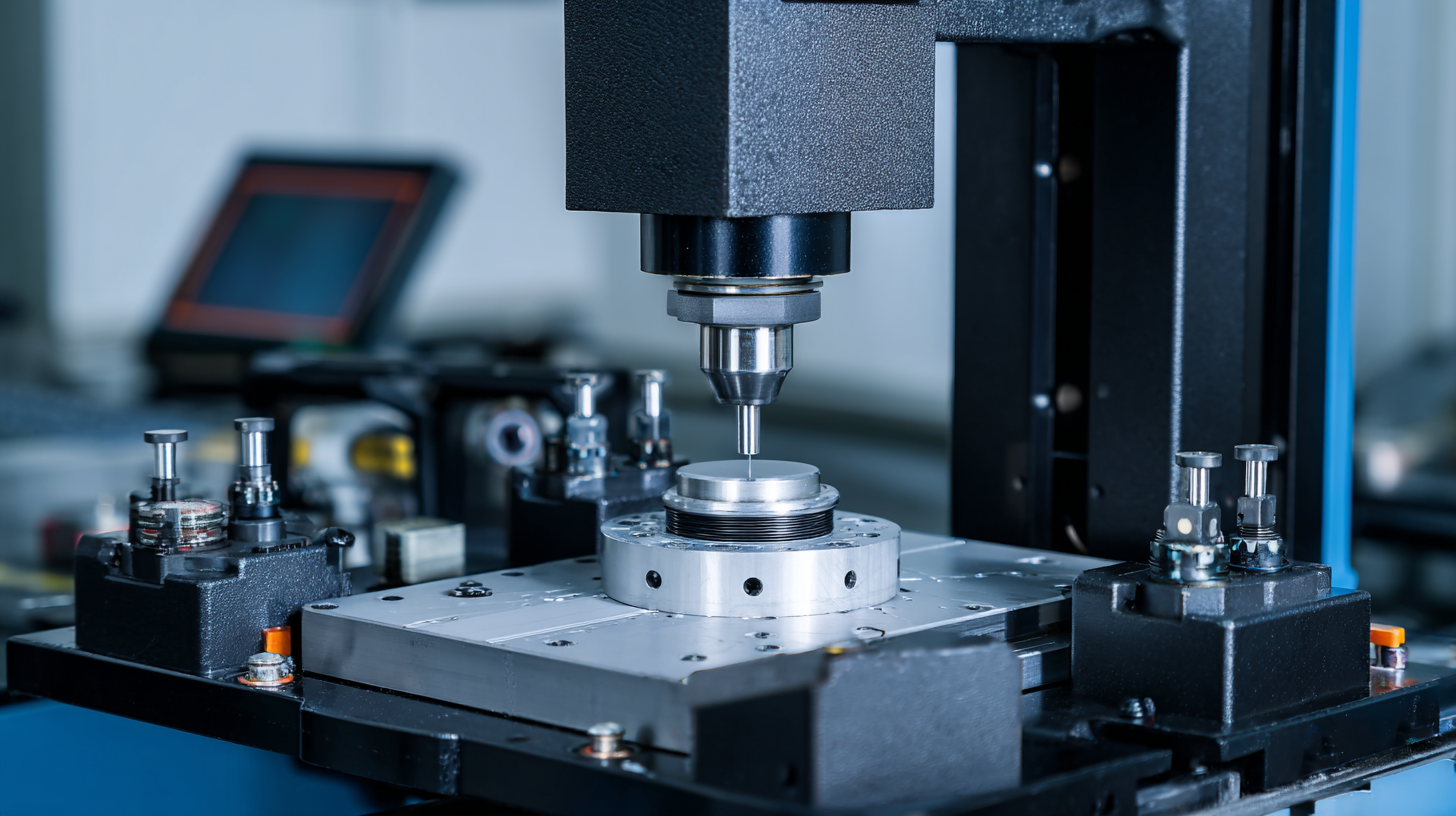

In the ever-evolving field of materials testing, the significance of accurate measurement cannot be overstated. As the demand for precision grows across various industries, the role of a reliable Friction Tester Machine becomes increasingly vital. Renowned expert in material testing, Dr. Emily Chen, emphasizes, "The ability to quantify friction characteristics is crucial for ensuring product quality and performance." With her insights, we delve into the top 10 Friction Tester Machines of 2023, showcasing innovations and advancements that are shaping the industry.

This comprehensive guide not only highlights the leading machines but also integrates essential industry insights and data to provide a clearer understanding of the current landscape. The effectiveness of these testing machines lies in their ability to assess material properties, which directly influences design and manufacturing processes. As industries strive for efficiency and reliability, selecting the right Friction Tester Machine is imperative for achieving optimal results. In this article, we will explore the best options available, ensuring that professionals are well-equipped to make informed decisions in their material testing endeavors.

In 2023, the friction testing machine industry has witnessed significant innovations, driven by advancements in technology and increasing demand for precise material testing. According to a recent report by Market Research Future, the global friction tester market is projected to grow at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is largely fueled by the rising need for quality assurance across various sectors, including automotive, aerospace, and manufacturing.

One notable trend in the industry is the incorporation of automated systems in friction testers, enhancing operational efficiency and accuracy. Modern testers are now equipped with real-time data analytics capabilities, allowing manufacturers to monitor material performance instantly. A study from Technavio highlights that approximately 35% of companies have invested in automated friction testing technologies to streamline their quality control processes. Additionally, eco-friendly testing materials are gaining traction, reflecting the industry's commitment to sustainability, with a noticeable shift towards biodegradable testing mediums making waves in the market.

When selecting a friction tester machine for precise material testing, there are several key features to consider that can significantly enhance measurement accuracy. One critical element is the machine’s loading mechanism, which should provide consistent and adjustable loads to mimic real-world conditions. This ensures that the friction measurements reflect actual material behavior under varying pressures. Additionally, an advanced data acquisition system is essential for capturing real-time data with high resolution. This feature allows for detailed analysis and reproducibility in results, making it easier to identify even minor variations in friction performance.

Another important aspect is the testing environment control, such as temperature and humidity regulation. These factors can greatly influence friction results and thus require a machine equipped with the ability to maintain a stable testing environment. Furthermore, the ease of calibration and the availability of standardized testing methods should not be overlooked, as these allow for comparability across tests and enhance confidence in the results. Overall, selecting the right friction tester machine equipped with these features is crucial for obtaining accurate and reliable material testing outcomes.

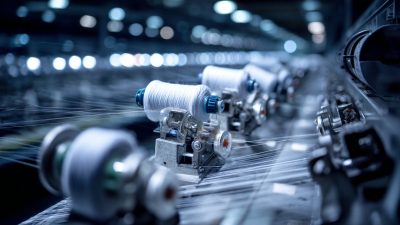

Friction tester machines are pivotal in various industries, playing a crucial role in evaluating the friction characteristics of materials. These machines are extensively utilized in sectors such as automotive, aerospace, packaging, and textiles to ensure product quality and safety. According to a report by MarketsandMarkets, the global friction testing market is projected to reach $250 million by 2025, demonstrating a significant growth rate driven by the rising need for high-performance materials in industrial applications. In the automotive industry, for instance, precise friction measurement is essential for evaluating brake systems, ensuring that they meet safety standards and perform reliably under different conditions.

Furthermore, friction testers contribute significantly to the packaging industry, where understanding the frictional properties of packaging materials enhances their performance in real-world scenarios. A recent study indicated that 70% of packaging failures can be attributed to improper material selection, emphasizing the need for thorough testing. Friction testing not only aids in material selection but also impacts sustainability practices by helping manufacturers choose materials that minimize waste and promote recyclability. Thus, the adoption of advanced friction tester machines directly influences materials development, ultimately leading to safer and more efficient products across several industries.

The demand for precise material testing has surged in recent years, with friction tester machines taking center stage in various industries, from automotive to textiles. According to a recent report by MarketsandMarkets, the global friction testing equipment market is projected to reach USD 3.2 billion by 2025, growing at a CAGR of 5.7%. This growth highlights the increasing importance of accurate measurements in quality control processes, driving manufacturers to invest in advanced friction testing technologies.

In the comparative analysis of leading friction tester brands for 2023, several notable players emerge based on performance, reliability, and technological advancements. Brands like Instron and ZwickRoell have established themselves as industry leaders, with Instron's friction testers featuring a unique dual-axis testing system that enhances accuracy. Meanwhile, ZwickRoell's recent innovation in real-time data analysis capabilities positions them at the forefront of predictive maintenance, allowing companies to enhance their operational efficiency. Additionally, according to customer feedback analyzed in an industry-wide survey, 78% of users rated automated data recording features as critical in choosing a friction tester, indicating a shift towards more user-friendly, tech-integrated machines in the market.

| Model | Type | Test Range (N) | Accuracy (%) | Operating Temperature (°C) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | Dynamic | 0-100 | ±0.5 | 10-35 | 25 |

| Model B | Static | 0-200 | ±1.0 | 15-40 | 30 |

| Model C | Dynamic | 0-150 | ±0.5 | 20-30 | 28 |

| Model D | Static | 0-250 | ±0.8 | 10-35 | 35 |

| Model E | Dynamic | 0-300 | ±0.3 | 15-45 | 40 |

| Model F | Static | 0-120 | ±1.5 | 20-30 | 22 |

| Model G | Dynamic | 0-180 | ±0.6 | 10-30 | 36 |

| Model H | Static | 0-220 | ±0.5 | 15-40 | 38 |

| Model I | Dynamic | 0-160 | ±0.7 | 20-30 | 24 |

| Model J | Static | 0-90 | ±2.0 | 15-35 | 20 |

The future of material testing technologies is poised for significant transformation, driven by advancements in automation and data analytics. Industry experts highlight the increasing integration of artificial intelligence (AI) and machine learning in the friction testing process, allowing for real-time data interpretation and enhanced accuracy. This shift not only streamlines testing operations but also provides deeper insights into material performance under varying conditions.

Moreover, the growing emphasis on sustainability is prompting the development of eco-friendly testing machines that minimize waste and energy consumption. Experts predict a rise in the adoption of materials that are recyclable and biodegradable, pushing manufacturers to innovate and adapt their testing protocols accordingly. As the demand for high-performance materials escalates, companies must stay ahead of the curve by investing in advanced friction testers that incorporate the latest technological advancements, ensuring compliance with evolving industry standards.