Home

Home

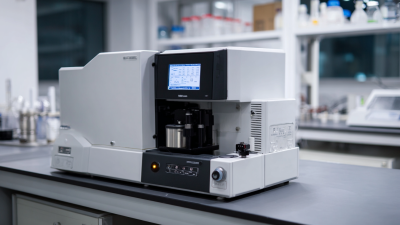

In the realm of material testing, ensuring optimal quality control is paramount, and one pivotal tool in this process is the Friction Tester Machine. These advanced devices play an essential role in measuring the frictional properties of various materials, crucial for determining their performance and reliability in diverse applications. By employing sophisticated testing methodologies, the Friction Tester Machine not only facilitates accurate assessments of material behavior under stress but also aids manufacturers in adhering to industry standards. This technology empowers engineers and quality control specialists to make informed decisions, reduce product failures, and enhance overall safety and reliability. As advancements in testing technology continue to evolve, integrating cutting-edge Friction Tester Machines into quality control protocols becomes a strategic necessity for any organization aiming to uphold high-quality benchmarks in their products.

Friction testers play a crucial role in quality control processes across various industries by providing insights into the frictional properties of materials. Understanding how materials interact under different conditions is essential for ensuring product reliability and performance. By accurately measuring static and dynamic friction coefficients, friction testers help identify potential issues in material selection and application, allowing manufacturers to make informed decisions before production.

Moreover, the relevance of quality control in today’s competitive market cannot be overstated. Advanced friction tester machines utilize cutting-edge technology to deliver precise and repeatable results, enhancing the efficiency of the testing process. These machines are designed to simulate real-world conditions, providing data that can predict a material's behavior in practical applications. The integration of friction testing in quality control not only increases product integrity but also bolsters consumer trust, ultimately leading to improved market performance and reduced costs associated with failures and recalls.

| Material Type | Coefficient of Friction | Test Method | Test Conditions | Notes |

|---|---|---|---|---|

| Rubber | 0.9 | ASTM D1894 | Dry, Room Temperature | High traction, suitable for high-friction applications. |

| Metal | 0.3 | ISO 8295 | Lubricated, Controlled Environment | Critical for machinery applications. |

| Plastic | 0.5 | ASTM D5420 | Ambient Humidity, Room Temperature | Suitable for packaging materials. |

| Glass | 0.4 | ASTM C1116 | Dry, Various Temperatures | Important for safety applications. |

When selecting an advanced friction tester machine, several key features can significantly enhance your quality control process. First and foremost, accuracy is paramount. Look for machines that provide precise measurements of friction coefficients under various conditions. This ensures that material testing results are reliable and reproducible, which is essential for maintaining the integrity of your products.

Another crucial aspect is versatility. A machine capable of testing multiple material types—such as metals, plastics, and composites—can save time and resources. Additionally, consider machines that come with customizable testing protocols, allowing you to tailor the parameters to suit specific industry standards. User-friendly interfaces and advanced software integration can also streamline data analysis and reporting, making it easier to derive actionable insights from your tests.

These features collectively contribute to a robust quality control framework, ensuring that your materials meet regulatory and performance criteria.

Friction testing is an essential component of quality control in material evaluation, ensuring that products meet specific performance standards. Implementing a structured approach begins with selecting the right friction tester machine tailored to your material and testing requirements. According to the American Society for Testing and Materials (ASTM), using advanced friction testers can enhance accuracy by up to 30%, providing more reliable results than traditional methods. It’s crucial to define the parameters of testing, including load, speed, and environmental conditions, to mirror real-world applications effectively.

Once the equipment is in place, the next step is to establish a standardized testing protocol. This includes calibrating the machine according to manufacturer specifications and performing routine checks to ensure consistency. Research from the International Organization for Standardization (ISO) indicates that organizations that adopt rigorous testing protocols can reduce material failures by 40%. By thoroughly documenting the testing procedures and results, businesses can maintain compliance and track trends over time, leading to improved quality control and product reliability.

Maintaining and calibrating your friction test equipment is vital for ensuring accurate and reliable results in material testing. Regular maintenance not only extends the lifespan of your equipment but also enhances the precision of your tests. Always begin by thoroughly cleaning the testing surfaces to remove any contaminants that could affect results. Additionally, check for any wear or damage in the components and replace them as needed.

Tips: Schedule regular calibration sessions, ideally every six months, to keep the equipment in optimal condition. Using certified calibration weights and following the manufacturer’s guidelines will help maintain accuracy. Document all maintenance and calibration activities for compliance and to monitor the performance trends over time.

Moreover, ensure that your testing environment is stable; fluctuations in temperature and humidity can significantly impact results. Positioning the equipment on a solid, level surface will prevent vibrations that could alter readings. Always conduct a pre-test to check that all systems are functioning correctly, and familiarize yourself with any software updates or changes in testing protocols.

In the realm of material testing, analyzing friction test results is crucial for enhancing performance and reliability. Advanced friction tester machines provide precise data that can illuminate the interactions between materials under different conditions. Such insights enable manufacturers to select the best materials for their applications, ensuring long-lasting performance and reducing failures. By understanding the friction characteristics, businesses can optimize their products for specific environments and expectations.

In the realm of material testing, analyzing friction test results is crucial for enhancing performance and reliability. Advanced friction tester machines provide precise data that can illuminate the interactions between materials under different conditions. Such insights enable manufacturers to select the best materials for their applications, ensuring long-lasting performance and reducing failures. By understanding the friction characteristics, businesses can optimize their products for specific environments and expectations.

Tips for Effective Analysis: When evaluating friction test results, focus on key parameters such as coefficient of friction, wear patterns, and surface temperatures. It’s also essential to understand the context of your testing conditions, as variations in humidity and temperature can dramatically affect outcomes. Always compare results against established benchmarks to gauge the material’s suitability.

Moreover, employing data visualization techniques can significantly enhance the interpretation of friction test outcomes. Graphs and charts can make patterns more apparent and facilitate discussions with stakeholders about material selection and improvements. Daily calibration of your friction tester ensures accuracy, reinforcing the reliability of your test results and ultimately leading to superior material performance.