Home

Home

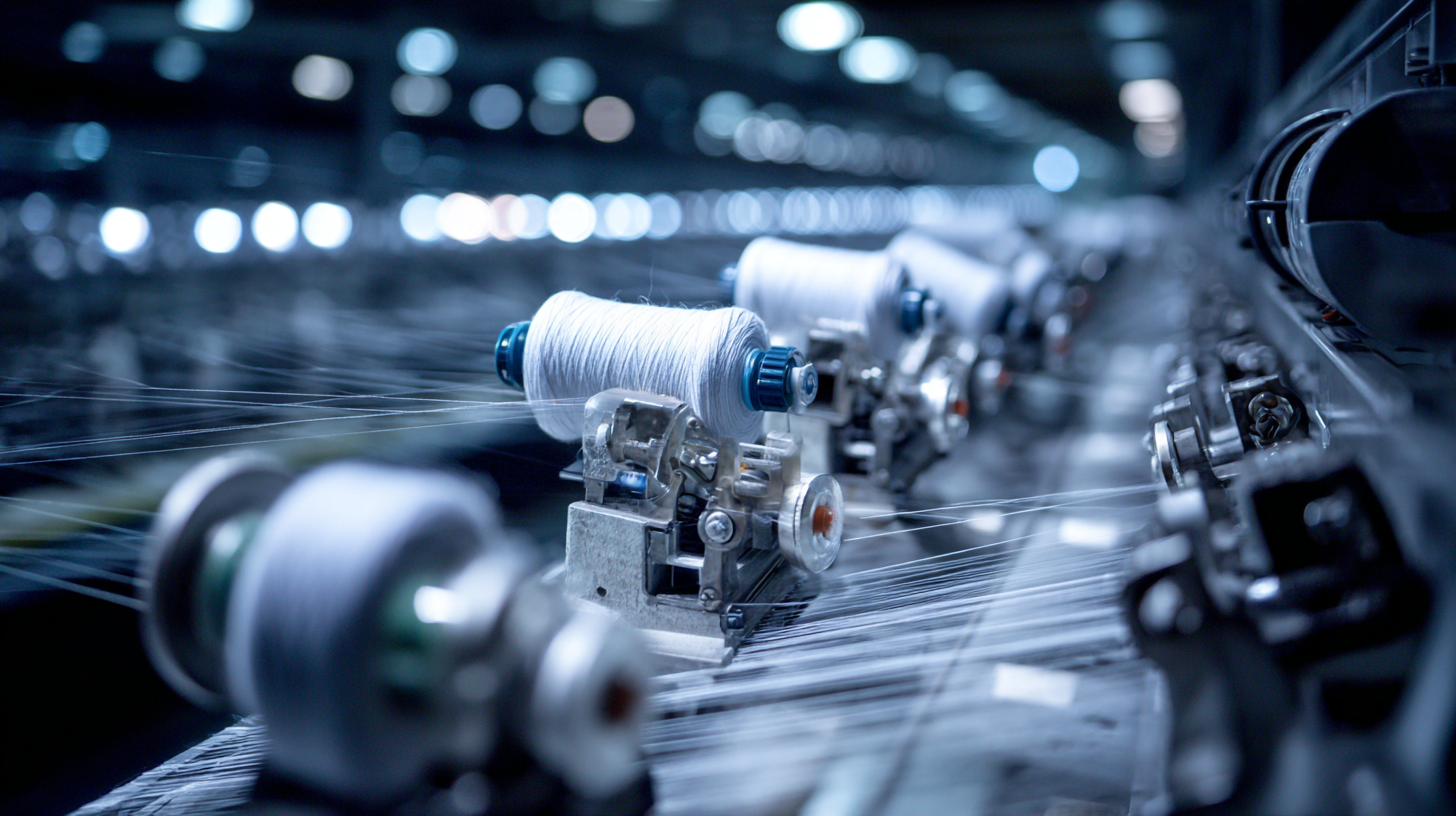

In today's fast-paced textile industry, ensuring product quality has become paramount, and the role of the Textile Testing Machine is crucial in this process. According to a report by Smithers Pira, the global textile testing equipment market is projected to reach $1.56 billion by 2025, highlighting the growing importance of advanced testing technologies in maintaining high standards. These machines not only facilitate compliance with international regulations but also enhance durability, safety, and performance of fabrics. As brands compete in a market that increasingly values quality and sustainability, textile testing machines are integral to quality assurance, offering detailed insights into material properties and helping manufacturers mitigate risks associated with defective products. Understanding how to effectively utilize these machines is essential for industry stakeholders aiming to improve product reliability and consumer trust.

Textile testing machines play a crucial role in ensuring product quality across the textile industry. According to a report by the International Textile Manufacturers Federation (ITMF), quality assurance is essential for maintaining customer satisfaction and fostering brand loyalty, with 75% of consumers willing to pay more for high-quality textiles. These machines are designed to assess various parameters such as tensile strength, shrinkage, colorfastness, and durability, which are vital for compliance with industry standards and regulations.

Textile testing machines play a crucial role in ensuring product quality across the textile industry. According to a report by the International Textile Manufacturers Federation (ITMF), quality assurance is essential for maintaining customer satisfaction and fostering brand loyalty, with 75% of consumers willing to pay more for high-quality textiles. These machines are designed to assess various parameters such as tensile strength, shrinkage, colorfastness, and durability, which are vital for compliance with industry standards and regulations.

Furthermore, the ability to conduct rigorous testing not only guarantees product reliability but also minimizes the risk of costly recalls. A study by the American Association of Textile Chemists and Colorists (AATCC) highlights that companies that implement comprehensive testing procedures can reduce defect rates by over 30%. This data underscores the significance of textile testing machines, as they help manufacturers identify flaws early in the production process, thereby enhancing overall efficiency and ensuring that only superior products reach the market.

Textile testing machines play a vital role in quality control processes, ensuring that fabrics and garments meet industry standards and consumer expectations. According to a 2022 report by MarketsandMarkets, the global textile testing market is projected to reach USD 5.8 billion by 2026, demonstrating the increasing emphasis on quality assurance in the textile industry. These machines assess various properties of textiles, including tensile strength, colorfastness, and shrinkage, allowing manufacturers to identify potential defects before products reach the consumer.

One of the key functions of textile testing equipment is to evaluate physical and mechanical properties, which are critical for performance in different applications. For instance, the use of tensile testing machines can determine the elongation and strength of fabrics, essential for products like activewear and outdoor gear. Additionally, colorfastness testing ensures that dyes withstand exposure to washing and sunlight, a significant factor, as reports indicate that 90% of consumers consider color retention when purchasing clothing. By integrating advanced textile testing machines into the quality control process, manufacturers can not only improve product durability and customer satisfaction but also reduce return rates and enhance brand reputation.

In the textile industry, consistent testing of materials and products is pivotal for maintaining brand reputation. Implementing rigorous quality assurance protocols through advanced textile testing machines ensures that every item meets the industry standards. This process not only helps in identifying defects early in the production cycle but also assures consumers of the product's reliability and performance. Brands that prioritize stringent testing practices can significantly reduce the risk of recalls and negative consumer feedback, which can tarnish their market standing.

Moreover, consistent testing fosters trust and loyalty among customers. When consumers recognize a brand’s commitment to quality through visible testing and certification, they are more likely to choose its products over competitors. This establishes a strong brand identity that aligns with excellence, safety, and durability. In an increasingly competitive landscape, investing in quality assurance through textile testing machines becomes not only a necessity for compliance but also a strategic advantage for brands aiming to cultivate lasting relationships with their customers.

| Testing Parameter | Frequency of Testing | Impact on Quality | Effect on Brand Reputation |

|---|---|---|---|

| Color Fastness | Every Batch | Ensures consistent color quality | High trust and customer loyalty |

| Tensile Strength | Monthly | Prevents fabric tears and defects | Promotes brand reliability |

| Shrinkage | Every Batch | Maintains size integrity | Enhances customer satisfaction |

| Pilling Resistance | Every Batch | Improves fabric appearance | Lowers return rates |

| Water Repellency | Quarterly | Enhances functional properties | Builds product reputation |

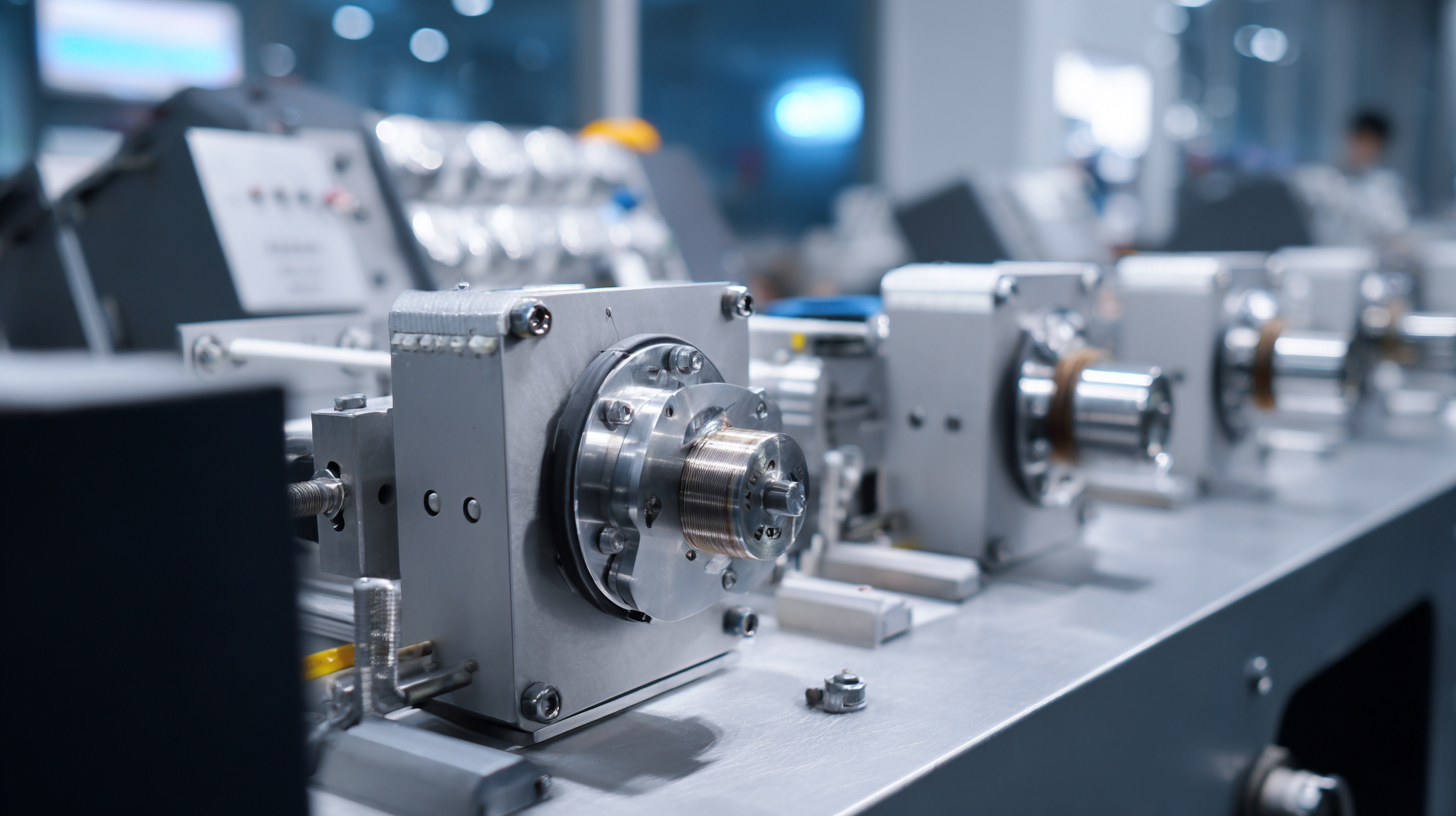

The evolution of textile testing machines has revolutionized quality assurance in the textile industry. Technological advancements have led to the development of sophisticated equipment that not only enhances accuracy but also boosts efficiency in testing processes. Modern machines incorporate automation and digitalization, allowing for real-time data analysis and reporting, which significantly reduces human error and subjectivity in evaluations. These improvements facilitate quicker turnaround times for testing results, enabling manufacturers to maintain stringent quality standards while keeping pace with market demands.

Moreover, the integration of advanced materials and smart technology has expanded the capabilities of textile testing machines. Instruments are now equipped with sensors and software that can assess textiles for a wide range of properties, from tensile strength to moisture management. This level of precision is crucial in meeting consumer expectations and regulatory requirements. As a result, textile testing machines have become indispensable tools for manufacturers striving to produce high-quality fabrics that align with current trends and sustainability goals. The continuous innovation in this field positions textile testing machines as a game changer in the quest for excellence in textile production.

In the textile industry, implementing effective testing practices remains a significant challenge. According to a report by MarketsandMarkets, the global textile testing market is projected to reach $5.93 billion by 2025, highlighting the increasing necessity for stringent quality assurance measures. However, many manufacturers still struggle with inadequate testing infrastructure, which can lead to inconsistent product quality. A survey by Textile World revealed that over 40% of textile companies do not utilize advanced testing technologies, resulting in subpar material performance.

Moreover, the integration of innovative textile testing machines is often hindered by a lack of trained personnel. The International Organization for Standardization (ISO) emphasizes that proper training in testing methodologies significantly impacts the reliability of test results. Companies face the dual challenge of investing in advanced testing equipment while simultaneously ensuring adequate workforce training. To address these issues, many organizations are now collaborating with specialized testing laboratories to outsource quality assurance processes, thereby accessing expertise without the high costs associated with in-house capabilities. This shift not only enhances product quality but also streamlines operations in a competitive market environment.