Home

Home

The evolution of Textile Testing Equipment is set to transform the fabric industry as we know it, driven by emerging technologies and innovative practices. As textile manufacturers seek to enhance product quality, develop sustainable practices, and meet the increasing demands of consumers, advancements in testing equipment become crucial. This exploration focuses on the latest innovations and trends in textile testing, highlighting the significance of digital integration, automation, and real-time data analysis in ensuring superior quality control. By leveraging technologies such as artificial intelligence and machine learning, the future of textile testing not only promises improved accuracy but also promotes efficiency and agility in the production process. This article will delve into the transformative impact of these innovations, providing valuable insights and practical tips for industry professionals looking to stay competitive in a rapidly evolving landscape.

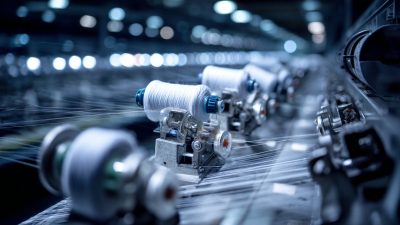

In recent years, the textile industry has witnessed a significant transformation driven by innovative technologies that are reshaping the landscape of textile testing equipment. Advanced automation techniques are becoming increasingly prevalent, enabling high-throughput testing that ensures greater efficiency and accuracy. Integrating artificial intelligence into testing protocols allows for predictive analytics, facilitating quicker decision-making processes and enhancing product quality. As the demand for sustainable practices rises, eco-friendly testing methods are also gaining traction, prompting manufacturers to adopt equipment that minimizes waste and energy consumption.

Additionally, the rise of smart textiles necessitates the development of sophisticated testing apparatus that can evaluate unique properties like moisture management and thermal insulation. This has led to innovations such as wearable testing devices and IoT-integrated equipment, which not only assess performance but also provide real-time feedback to manufacturers and consumers alike. As the industry continues to evolve, embracing these cutting-edge technologies will be crucial in meeting the diverse and dynamic needs of the market, ensuring that textile testing remains at the forefront of quality assurance and innovation.

The textile testing equipment industry is witnessing a transformative shift toward sustainability and eco-friendly solutions. As manufacturers and consumers alike prioritize environmental impact, innovation in testing methodologies is critical. For instance, the emphasis on sustainable materials is reshaping the parameters for performance testing, requiring equipment that not only measures durability but also assesses biodegradability and the overall life cycle of textiles. This aligns with the growing demand for eco-conscious products, pushing the industry to adapt and innovate accordingly.

In parallel, the eco-friendly narrative extends beyond textiles into related sectors such as plastics and packaging, echoing a broader industry trend. The market for recycled plastic solutions is expected to surge, reaching $76.35 billion by 2033, which reflects a significant shift towards materials that contribute to a circular economy. Advances in testing equipment will be imperative to verify the efficacy and safety of these materials, ensuring that all aspects of textile production align with sustainability goals. As the sector evolves, embracing these innovative trends in testing will be vital for maintaining industry standards while fostering a greener future.

This chart illustrates the key trends in textile testing equipment innovations, emphasizing the growing importance of sustainability and eco-friendly solutions. Each category represents a critical area in which advancements are occurring, rated on a scale of 1 to 10 based on their significance in the industry.

The textile industry is undergoing a significant transformation with the integration of automation and artificial intelligence (AI) into testing processes. As companies strive to enhance efficiency and reduce costs, the introduction of AI agents in textile testing is paving the way for rapid analysis and improved quality control. These smart systems can interpret vast amounts of data much faster than human operators, allowing for real-time adjustments that lead to more accurate results and reduced waste.

Tips: When implementing AI into your textile testing processes, start with clear objectives. Identify specific areas where automation can improve efficiency, such as fabric performance analysis or color consistency checks. Additionally, invest in training for your team to ensure they understand how to leverage AI tools effectively.

Furthermore, embracing automation can lead to significant innovations in textile testing equipment. Automated systems equipped with AI can perform repetitive tasks with high precision, facilitating a more streamlined workflow. This not only enhances productivity but also encourages a culture of innovation within textile companies, as teams can focus on more complex problem-solving rather than mundane testing procedures.

Tips: To stay ahead in the competitive textile market, regularly evaluate your equipment for potential upgrades. Collaborating with technology providers can help you select the right tools that incorporate the latest AI advancements, ensuring your testing processes are both efficient and cutting-edge.

| Innovation | Description | Benefits | Implementation Stage |

|---|---|---|---|

| Automated Fabric Testing | Integration of robotic systems for fabric sampling and testing. | Increased efficiency and reduced labor costs. | Pilot Testing |

| AI-Driven Quality Analysis | Utilization of machine learning algorithms to detect fabric defects. | Enhanced accuracy in quality control. | Research Phase |

| Remote Testing Solutions | Cloud-based platforms allowing real-time testing analysis. | Convenient access and collaborative analysis. | Development Stage |

| Smart Sensor Technologies | Advanced sensors to monitor fabric properties in real-time. | Improved data accuracy for better decision making. | Prototype Testing |

| Blockchain for Traceability | Using blockchain to enhance transparency in textile testing. | Assured authenticity and sustainability. | Exploration Stage |

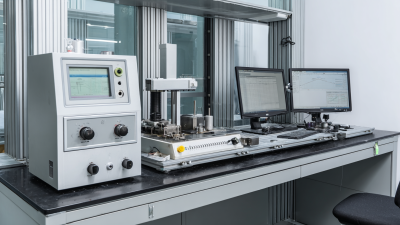

The landscape of textile testing is undergoing significant transformation influenced by emerging standards and regulations. With the establishment of new laboratories aimed at enhancing compliance, there is an increasing demand for high-quality testing in line with stricter regulations. This trend reflects a broader push within the industry for innovations that not only meet existing safety and quality benchmarks but also anticipate future requirements as consumer expectations evolve. As brands and manufacturers strive to adhere to these emerging standards, the integration of advanced technologies becomes crucial in streamlining the testing process and improving accuracy.

Moreover, the emphasis on sustainability is reshaping the future of textile testing. Regulatory mandates are now prioritizing circularity and eco-friendliness, encouraging the development of fabrics and materials that comply with environmental standards. The innovative approach to textile testing includes the adoption of AI-enabled solutions that facilitate more efficient assessments of fabric properties, further underscoring the role of regulation in driving technological advancements. As the industry moves towards a more sustainable model, the interplay between regulatory compliance and innovation will define the direction of textile testing equipment in the coming years.

Data analytics is playing a transformative role in the textile testing industry, enhancing both accuracy and efficiency. According to a report by MarketsandMarkets, the global textile testing market is expected to grow from $3.5 billion in 2021 to $4.5 billion by 2026, driven largely by the integration of advanced data analytics tools. These tools allow for real-time monitoring of fabric properties, enabling manufacturers to make data-driven decisions, which reduce waste and improve product quality.

Moreover, the application of predictive analytics in textile testing has gained traction. By leveraging machine learning algorithms, companies can predict the performance and longevity of fabrics before they reach the consumer market. A study published by the International Textile and Apparel Association indicates that companies utilising predictive analytics have seen a 30% reduction in testing times, simultaneously enhancing compliance with various international standards. This not only accelerates the go-to-market time for new textile products but also ensures that they meet the required standards for quality and safety, ultimately leading to increased consumer trust.