Home

Home

The textile industry is at a pivotal juncture, where the intersection of technology and sustainability is becoming increasingly prominent. The advancement of Textile Lab Equipment plays a crucial role in driving innovative fabric solutions that cater to both environmental needs and consumer demands. Recent studies indicate that the global market for sustainable textiles is expected to reach $120 billion by 2026, highlighting the urgent need for rigorous testing and development processes facilitated by advanced lab equipment. Furthermore, reports suggest that the adoption of eco-friendly materials and practices could reduce the carbon footprint of the textile sector by up to 30% over the next decade. Thus, this exploration into the future of Textile Lab Equipment not only underscores its significance in developing sustainable fabric innovations but also reflects a broader shift towards responsibility and efficiency in textile manufacturing practices.

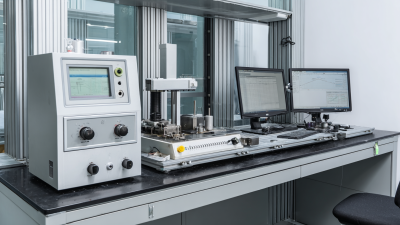

The textile industry is witnessing a transformative shift, driven by innovative technologies that are reshaping the landscape of textile lab equipment. Recent reports from the Bureau of Labor Statistics indicate that advancements in automation and data analytics are enhancing the efficiency of textile testing processes. For instance, the integration of AI-driven testing equipment can reduce fabric verification time by up to 50%, facilitating quicker turnarounds in product development. This shift not only accelerates innovation but also supports a more agile response to market demands.

Furthermore, advancements such as digital fabric printing and eco-friendly dyeing techniques are emerging as critical drivers of sustainable fabric innovations. According to a study by the Textile Exchange, companies adopting sustainable practices saw a 20% increase in consumer preference and loyalty. By investing in modern lab equipment that supports these technologies, manufacturers can improve their sustainability metrics and reduce waste, leading to a more responsible production cycle. Robotics and IoT-enabled devices are also creating more precise and efficient testing environments, allowing for better quality control and reduced resource consumption, which are vital for long-term sustainability in the textile sector.

| Equipment Type | Innovative Technology | Sustainability Impact | Research Focus |

|---|---|---|---|

| Fiber Testing Machine | Automated Fiber Identification | Reduction in Waste through Accurate Fiber Sorting | Synthetic vs. Natural Fibers |

| Color Matching Software | AI-Driven Color Analysis | Minimization of Dye Usage | Eco-Friendly Dyes |

| Textile Testing Instruments | Advanced Mechanical Testing | Improving Durability and Longevity | Biodegradable Materials |

| Weaving Machines | Smart Loom Technology | Efficient Resource Utilization | Sustainable Weaving Techniques |

| Environmental Chambers | Climate Adaptability Testing | Assessing Fabric's Environmental Impact | Recycled Fabrics |

Integrating sustainability metrics into textile testing processes is essential for advancing eco-friendly innovations in fabric production. By employing quantitative measures that assess environmental impact throughout the textile life cycle, manufacturers can identify areas for improvement and optimize resource usage.

Key metrics might include water consumption, energy expenditure, and chemical usage, all of which play a significant role in the overall sustainability of textile products. By embedding these metrics into standard testing protocols, the industry can drive a stronger commitment to environmentally responsible practices.

Moreover, as consumers become increasingly aware of sustainability issues, integrating these metrics into testing processes not only meets market demand but also enhances brand transparency and accountability. Companies that prioritize sustainability in their textile testing can attract environmentally conscious consumers and differentiate themselves in a competitive market.

The future of textile lab equipment must therefore focus on advanced technologies that support comprehensive data collection and analytics, providing manufacturers with actionable insights to create sustainable fabrics effectively. This convergence of technology and sustainability metrics will ultimately lead to more innovative and responsible textile solutions.

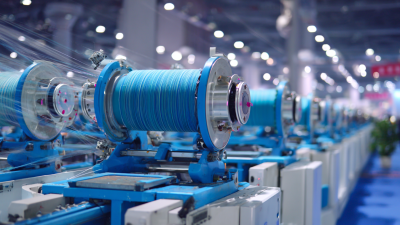

As the textile industry moves towards more sustainable practices, automation plays a crucial role in enhancing fabric development. Innovative technologies such as smart automation in garment manufacturing are optimizing production processes, reducing waste, and improving efficiency. According to recent market reports, the nonwoven fabrics market is expected to reach a value of USD 31.35 billion by 2035, driven by advancements in automation techniques across various end-use industries, including hygiene and filtration. This signifies a shift towards increased productivity while promoting environmentally friendly solutions in textile manufacturing.

As the textile industry moves towards more sustainable practices, automation plays a crucial role in enhancing fabric development. Innovative technologies such as smart automation in garment manufacturing are optimizing production processes, reducing waste, and improving efficiency. According to recent market reports, the nonwoven fabrics market is expected to reach a value of USD 31.35 billion by 2035, driven by advancements in automation techniques across various end-use industries, including hygiene and filtration. This signifies a shift towards increased productivity while promoting environmentally friendly solutions in textile manufacturing.

Tips: Embracing automation in fabric development not only enhances operational efficiency but also allows for better quality control. Producers can leverage automated systems to ensure consistency in product quality and reduce the likelihood of defects during manufacturing.

Moreover, as generative AI becomes more integrated into textile lab equipment, the potential for innovation in fabric design is immense. By utilizing AI-driven tools, companies can accelerate the development of new textiles that align with sustainable practices, ultimately positioning themselves as leaders in an increasingly eco-conscious market.

Tips: Stay informed about the latest automated technologies to identify opportunities for innovation within your fabric development processes. Engaging in continuous learning about these advancements can lead to enhanced competitiveness and sustainability in your product offerings.

The exploration of emerging materials in the textile industry

is fundamentally linked to the testing requirements for sustainable textiles. As the demand for eco-friendly fabrics grows,

innovative materials such as e-textiles and algae-based textiles

are being researched for their ability to balance sustainability and performance. The development of standards

for these materials is crucial to ensure their viability in the market, necessitating comprehensive testing protocols

that address durability, biodegradability, and overall ecological impact.

Fashion weeks serve as a vital platform for showcasing these advancements, allowing designers and textile innovators

to present their sustainable creations to a global audience. This visibility not only promotes consumer awareness

but also encourages collaboration among stakeholders in the apparel industry. Simultaneously, the evolution of

testing methods adapted to new materials is essential to reinforce their reliability and environmental benefits,

ensuring that sustainable textiles can meet the rigorous demands of both the fashion industry and consumers.

The future of textile lab equipment is pivotal for advancing sustainable fabric innovations. As the industry gravitates towards eco-friendly practices, investing in state-of-the-art lab equipment becomes essential. These investments not only enhance the efficiency of testing and production processes but also enable researchers and manufacturers to experiment with sustainable materials and techniques. By adopting advanced textile testing technologies, labs can better analyze the environmental impact of fibers and dyes, leading to the development of fabrics that are both high-quality and environmentally responsible.

Strategically investing in green innovations also requires a shift in mindset among stakeholders in the textile industry. Collaborative partnerships between textile labs, universities, and eco-conscious manufacturers can facilitate the sharing of resources and knowledge. Such alliances can accelerate the evolution of sustainable textile production methods and foster a culture of innovation that prioritizes environmental sustainability. By embracing these investment strategies, textile labs can not only future-proof their operations but also play an integral role in shaping a more sustainable fabric industry for the coming decades.