Home

Home

The development of advanced materials has significantly transformed various industries, emphasizing the need for precise testing methods to ensure quality and reliability. One such essential tool in material testing is the Friction Peel Tester, which plays a crucial role in evaluating the adhesion properties of laminated materials and coatings. According to a report by the Materials Research Society, over 30% of product failures in industries such as automotive and aerospace can be traced back to inadequate adhesion performance. This underscores the importance of using specialized testing equipment like the Friction Peel Tester, which quantifies the peel adhesion and provides invaluable data for optimizing material performance.

By understanding the functionality and significance of this testing device, manufacturers can better navigate the complexities of material selection and ensure their products meet stringent safety and operational standards.

Friction peel testing plays a crucial role in assessing the adhesion strength of various materials, providing valuable insights for industries ranging from packaging to aerospace. This method evaluates the bond strength between layers of materials by measuring the force required to peel them apart under controlled conditions. According to a study published in the "Journal of Adhesion Science and Technology," strong adhesion is essential for the performance and durability of multi-layered materials, with failure modes often resulting from inadequate bonding. The friction peel tester quantifies these properties, offering a reliable benchmark for quality control and material selection.

In practical applications, the data obtained from friction peel testing can inform significant decisions in material engineering. For example, the "Institute of Packaging Professionals" has reported that improper adhesion can lead to failure in packaging integrity, contributing to economic losses estimated at $2 billion annually in the food industry alone. By implementing friction peel testing, manufacturers can ensure that their products meet the necessary strength requirements, ultimately enhancing safety and customer satisfaction. As industries continue to innovate, the ability to accurately measure and understand adhesion strength will remain vital for product development and reliability.

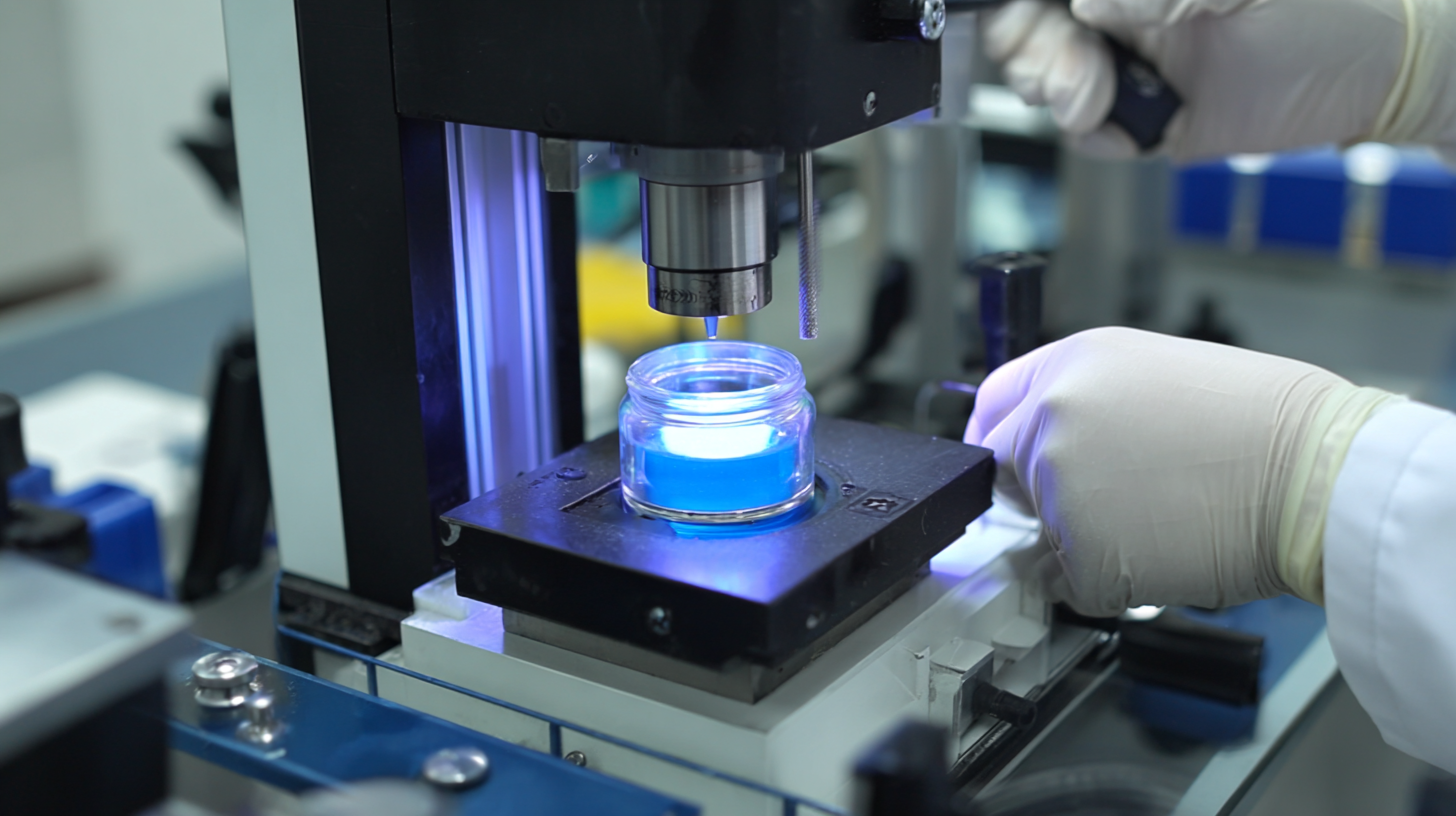

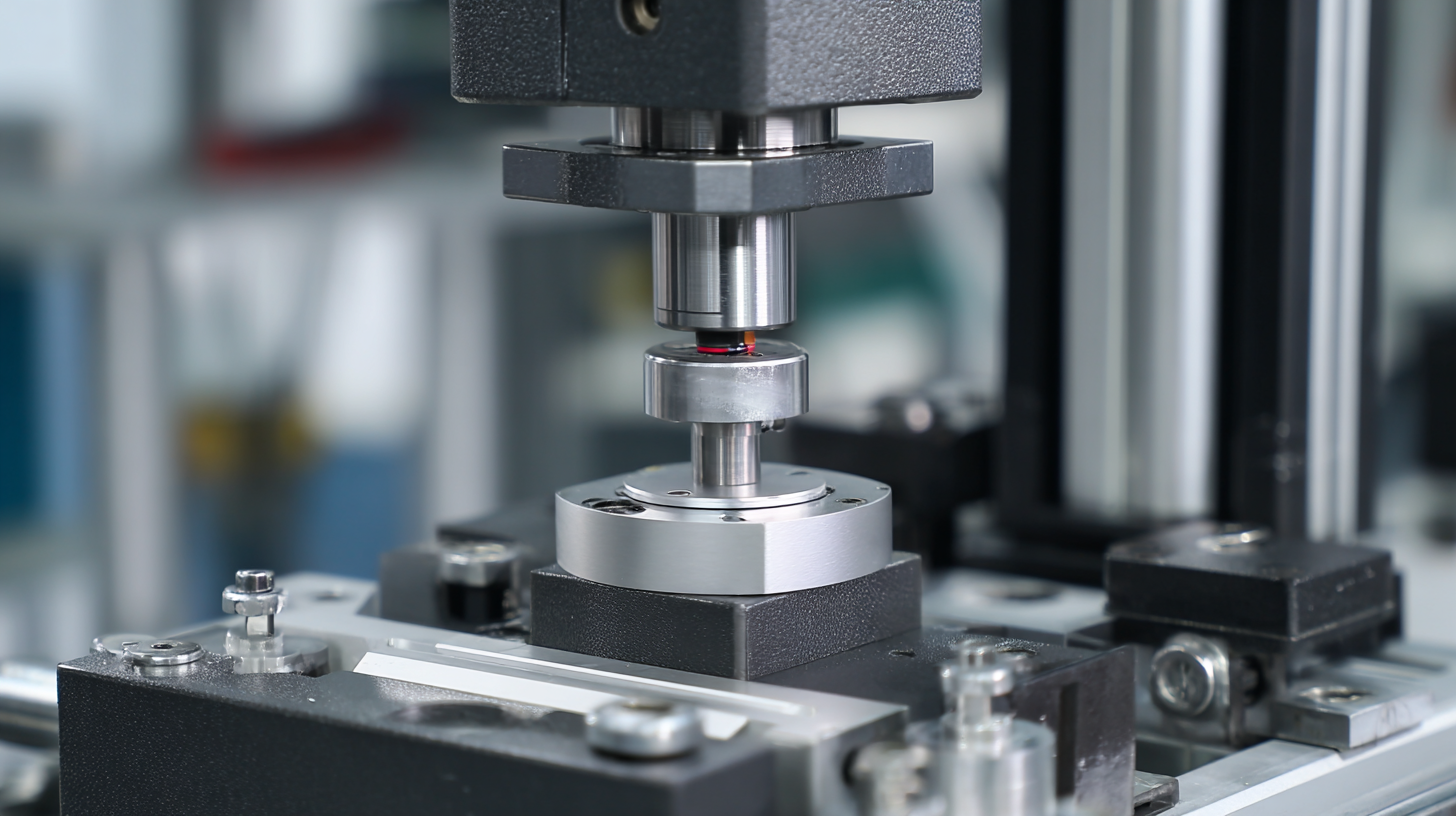

The Friction Peel Tester is a crucial device in material testing, designed to evaluate the adhesion properties of flexible and rigid materials. It operates on the principle of measuring the force required to peel apart bonded layers, providing vital data about adhesive strength, durability, and performance under various conditions. According to the Adhesive and Sealant Council, nearly 80% of product failures are attributed to inadequate adhesion, making the friction peel tester an essential tool in quality control across numerous industries, including automotive and electronics.

Key components of the Friction Peel Tester include a loading mechanism, a peel fixture, and a precision control system. The loading mechanism applies a controlled force to the material sample, while the peel fixture ensures the proper alignment of the layers being tested. Additionally, the software integrated into modern testers offers advanced data analysis, allowing engineers to interpret results accurately. Industry reports suggest that materials subjected to standardized tests using friction peel testers demonstrate at least a 30% improvement in bond integrity during real-world applications, highlighting its significance in product development and safety assessments.

| Component | Functionality | Importance | Measurement Range |

|---|---|---|---|

| Grip Mechanism | Holds the sample securely during testing. | Ensures consistent and repeatable results. | N/A |

| Load Cell | Measures the force applied during peeling. | Critical for determining adhesive strength. | 0-500 N |

| Control System | Controls test parameters and data collection. | Facilitates automation and efficiency in testing. | N/A |

| Testing Jig | Holds the samples in place and aligns them. | Ensures accurate testing alignment and minimizes errors. | Varies based on sample dimensions |

| Data Acquisition System | Collects and analyzes test data. | Important for reporting and quality assurance. | N/A |

The friction peel test is an essential procedure in materials testing, particularly for adhesive bonds and multi-layered materials. To conduct a friction peel test, begin by preparing your specimens according to the material properties and dimensions specified in standards such as ASTM D6862. This ensures consistency and reliability in results. Next, securely mount the specimen in the testing apparatus, ensuring that the orientation aligns with the predetermined peeling direction, which is crucial for obtaining accurate data.

Once the setup is complete, initiate the test by applying a controlled load to create a peeling force. Monitoring the force required to peel the adhesive layers apart provides insights into the bond strength and overall durability of materials. According to a report by the Adhesive and Sealant Council (ASC), proper execution of friction peel tests can reveal critical performance indicators, such as cohesive failure rates, which can reach up to 70% in high-performance adhesives. This data is vital for industries reliant on robust material bonding, such as automotive and aerospace sectors, where even slight adhesive failures can have significant operational consequences. Properly following this step-by-step guide ensures not only the accuracy of your test results but also the safety and durability of your final products.

Friction peel testing is a critical process in evaluating adhesive bonds, particularly in the realm of material science and engineering. The test measures the energy required to separate two bonded materials under a specific load and speed, providing valuable insights into the adhesive's performance under practical conditions. Interpreting the results from friction peel testing involves examining the force-displacement curves generated during the test, which reflect the material's adhesive strength and any cohesive failures that may occur.

One key aspect of the data is the peak load, which indicates the maximum adhesive strength before failure occurs. A higher peak load typically signifies a stronger bond, while variations in the slope of the force-displacement curve can reveal critical information about the material's elasticity and toughness. Additionally, the area under the curve can be analyzed to determine the total work required to peel the materials apart, which is essential in assessing the long-term reliability of the adhesive in real-world applications. By understanding these results, engineers and researchers can optimize adhesive formulations and improve product designs, ensuring enhanced performance and durability in their applications.

Friction peel testing is a vital process utilized across various industries, particularly in automotive, packaging, and agricultural sectors. This testing method evaluates the adhesion and peel strength of materials, ensuring that products meet stringent quality standards. For instance, in the automotive industry, the performance of adhesives in assembling sheet metal components is critical for crashworthiness. According to recent studies, a significant increase in adhesion strength can enhance vehicle safety, a factor that is paramount as safety regulations evolve.

Applications of friction peel testing extend to the food packaging industry, where seal integrity directly affects product freshness and safety. Studies indicate that materials tested for their peel strength can prevent leaks and maintain shelf life, thus preventing food spoilage and waste. The introduction of new testing machines with advanced peel testing capabilities marks a significant step forward in achieving precise measurements and ensuring quality control across these sectors.

Tip: When selecting materials for applications requiring strong adhesion, consider performing friction peel tests to compare various options. Testing not only guarantees compliance with industry standards but also enhances product reliability. Regular maintenance and calibration of testing equipment can further improve accuracy and consistency in results, ultimately leading to better product performance.