Home

Home

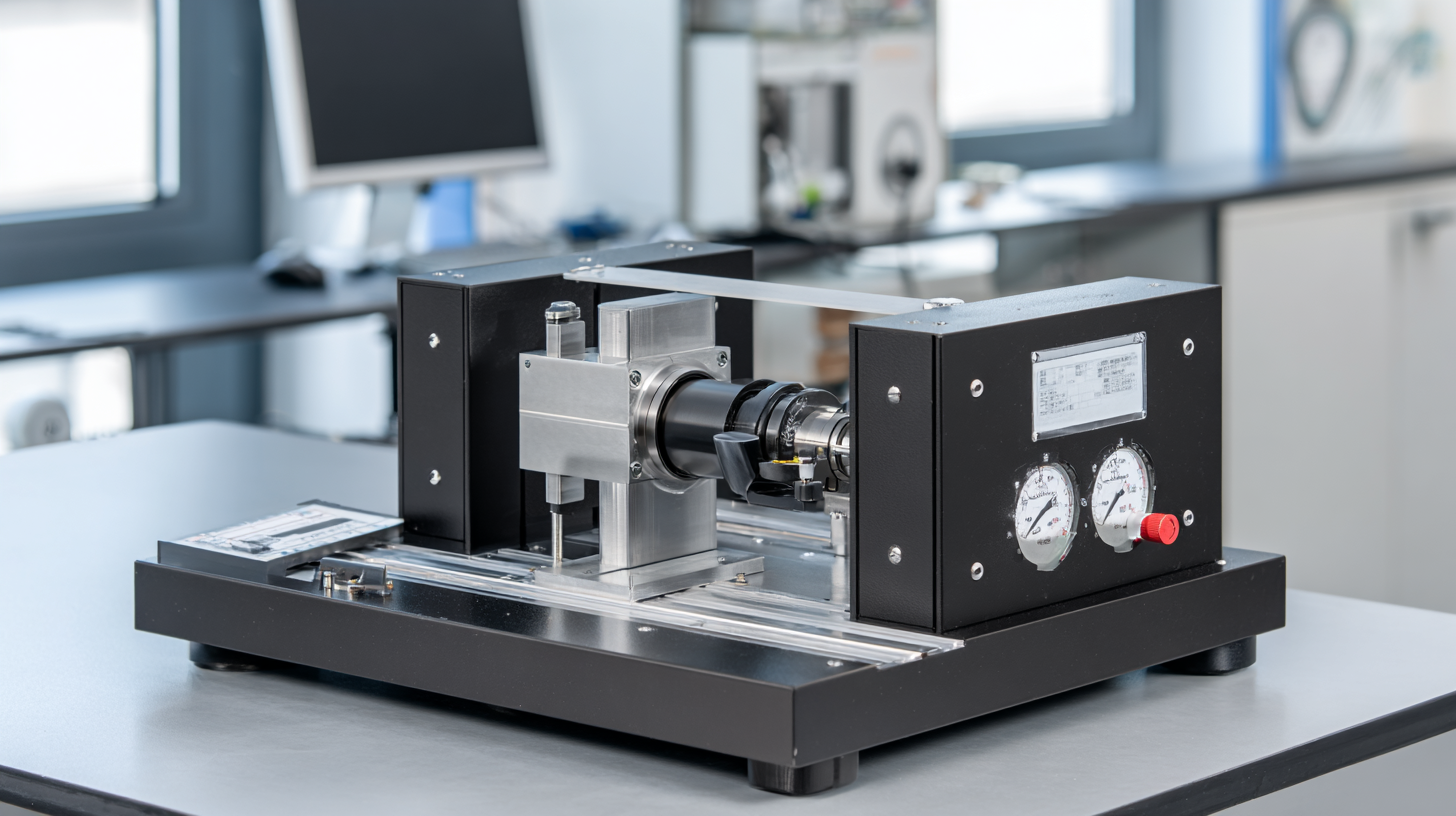

In the realm of material science innovation, the Friction Coefficient Tester plays a pivotal role in evaluating the interactions between various surfaces under different conditions. This essential tool is designed to measure the frictional forces that occur when two materials come into contact, providing critical data that informs material selection and performance assessment. As industries increasingly focus on enhancing material efficiency and durability, understanding friction coefficients becomes crucial for applications ranging from manufacturing processes to consumer products. By examining the behavior of materials through rigorous testing, researchers can develop advanced materials that minimize wear and improve functionality.

This article delves into the significance of Friction Coefficient Testers, exploring how they contribute to innovative solutions in material science and the ways in which they can be effectively utilized for various applications.

In the realm of engineering applications, the friction coefficient plays a crucial role in material selection, influencing the performance and longevity of various components. According to a report by the Materials Research Society, the friction coefficient affects not only the wear resistance of materials but also their energy efficiency during operation. For example, materials with lower friction coefficients can lead to reduced energy consumption in machinery, yielding savings that can be pivotal for large-scale operations.

Moreover, the selection of materials based on their frictional properties can significantly impact safety and functionality in critical applications. A study from the American Society of Mechanical Engineers highlights that inappropriate friction coefficients in automotive brake systems can lead to performance failures and increased wear rates, directly affecting vehicle safety. Thus, utilizing precision tools such as friction coefficient testers becomes imperative for engineers to evaluate and select the most suitable materials for their specific needs, ensuring optimal performance and reliability in diverse applications.

Recent advancements in friction coefficient testing technologies are transforming the landscape of material science and engineering. The significance of precise friction measurements cannot be overstated, as they directly influence the performance and safety of various materials in applications ranging from automotive to aerospace. For instance, according to a report by the American Society for Testing and Materials (ASTM), the adoption of high-precision friction coefficient testers has increased efficiency in material selection processes by about 30%, enabling engineers to make more informed decisions.

These advancements have led to the development of innovative testing equipment that offers real-time data and improved accuracy. Modern testers, such as those utilizing tribological simulation techniques, can assess friction properties under varying environmental conditions, which was previously a challenge. A study published in the Journal of Materials Science indicates that materials can exhibit up to a 25% variation in friction coefficients under different humidity levels. By integrating advanced technologies into friction testing, researchers are now equipped to better understand these dynamics, ultimately driving breakthroughs in material design and application longevity.

The friction coefficient is a crucial parameter in material science, particularly when assessing the performance and durability of various materials in applications like automotive and aerospace engineering. This comparative analysis of friction coefficient testers reveals diverse methods and standards utilized in evaluating frictional properties. Recent advancements illustrate the significance of precise testing methodologies, such as a study that examined tribometer precision on laboratory-grown dendritic snow—highlighting the impact of environmental variables on friction measurements.

Further emphasizing the relevance of friction coefficient testing, research focusing on the characterization of friction under near solidus forming (NSF) conditions has emerged. Using T-shape compression tests, these studies provide significant insights that aid in the optimization of manufacturing processes. Another notable investigation explored how contaminant film thickness affects walkway friction measurements, indicating the necessity for standardization in testing techniques to ensure safety and reliability. As the demand for innovative materials continues to rise, understanding the intricacies of friction coefficient beyond traditional metrics becomes ever more vital in adapting to evolving industrial standards.

In the realm of material science innovation, the friction coefficient plays a pivotal role in determining the performance and durability of materials in various applications. This parameter not only offers insights into material interactions but also aids researchers in designing materials that can withstand specific mechanical stresses. Real-world applications of friction coefficient data are evident in sectors like textiles, where innovations such as smart textile systems leverage these insights to create solutions for health monitoring, particularly among aging populations, thus addressing loneliness and enhancing their well-being.

Moreover, the understanding of friction in materials is crucial for advancements in engineering and sustainable technologies. For example, developments in thermoelectric materials and flexible wearable devices hinge on the effective manipulation of friction properties to achieve optimal energy conversion and sensing capabilities. The integration of machine learning in predicting the performance of materials further underscores the significance of friction coefficient data, paving the way for innovations that not only improve functionality but also promote sustainable practices in manufacturing and healthcare.

The ongoing evolution in friction coefficient research significantly impacts various industrial sectors. As the global clutch friction plate market is projected to grow from $12.59 billion in 2023 to approximately $24.63 billion by 2030, with a compound annual growth rate (CAGR) of 10.06%, understanding the role of friction coefficient testers is vital for material science innovation. These testers enable precise measurements of frictional properties, which are critical in the development of advanced materials that enhance performance and durability in automotive applications.

Future trends in friction coefficient research indicate a strong focus on sustainable materials and eco-friendly manufacturing processes. Industry experts predict that advancements in testing technologies will facilitate the creation of friction materials that not only perform better but also align with stringent environmental regulations. Moreover, the integration of artificial intelligence and machine learning in testing methodologies is expected to expedite material discovery and optimization, further driving the evolution of friction coefficient applications across various industries. As companies invest in R&D to harness these trends, a collaborative approach between academia and industry will be essential to remain competitive in an increasingly complex marketplace.