Home

Home

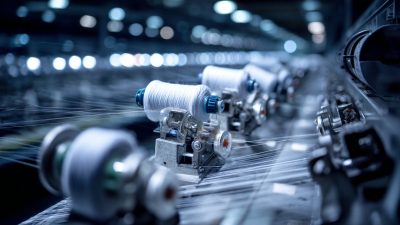

The textile industry is undergoing a transformative phase, driven by advancements in technology and a growing emphasis on quality assurance. One pivotal aspect of this evolution is the development of innovative Textile Lab Equipment, which is essential for accurate fabric testing and evaluation. According to a report by Smithers Pira, the global market for testing and measuring equipment for textiles is projected to reach $2.1 billion by 2024, reflecting a compound annual growth rate (CAGR) of 5.8%. This surge is largely attributed to the increasing demand for high-performance textiles and stringent standards in quality control. As manufacturers strive to enhance fabric performance and sustainability, the integration of digital technologies and automation in textile laboratories is becoming critical. These innovations not only streamline testing processes but also improve accuracy and efficiency in results. This article delves into the latest advancements in Textile Lab Equipment, highlighting how these innovations are shaping the future of fabric testing.

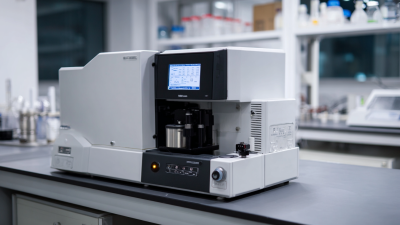

The integration of IoT and AI into textile lab equipment represents a significant leap forward in fabric testing methodologies. Smart fabric testing equipment is now capable of real-time data collection and analysis, enabling textile manufacturers to evaluate material properties with unparalleled precision. Equipped with sensors that monitor variables such as temperature, humidity, and tensile strength, these advanced devices provide instant feedback, allowing for quicker iterations in product development and quality assurance.

Moreover, the role of artificial intelligence in textile labs cannot be overstated. AI algorithms can analyze vast amounts of testing data to identify patterns and predict material performance under various conditions. This not only enhances the accuracy of test results but also facilitates proactive decision-making. By leveraging these technologies, textile labs are transforming traditional practices, leading to innovations that meet the evolving demands of the fashion and apparel industry while ensuring sustainability and efficiency in fabric production.

The textile industry is undergoing a significant transformation, driven by a growing emphasis on sustainability. Emerging trends in sustainable textile testing methods are proving essential for manufacturers aiming to reduce their environmental footprint. Innovations such as waterless dyeing technologies and bio-based fibers are gaining traction, allowing for more eco-friendly production processes. Additionally, advancements in testing equipment have made it easier to assess the ecological impact of materials at every stage of their lifecycle.

Tips: When exploring sustainable textile testing methods, consider investing in equipment that utilizes renewable energy sources. Look for suppliers that emphasize transparency in their testing processes, as this can provide a clearer understanding of a material’s environmental impact.

Moreover, the integration of digital technologies, like AI and machine learning, plays an increasingly vital role in advancing sustainable practices. These technologies enable more accurate predictions of material performance while minimizing waste in both production and testing phases. As the industry evolves, staying informed about these innovations will be crucial for professionals aiming to meet both quality standards and sustainability goals.

Tips: Engage with industry seminars and workshops focused on sustainable innovations, as they can provide valuable insights and foster connections with key experts and suppliers committed to eco-friendly practices.

| Testing Method | Description | Sustainability Aspect | Innovation Year |

|---|---|---|---|

| Waterless Dyeing | Technology that eliminates the need for water during the dyeing process. | Reduces water pollution and usage. | 2021 |

| Biodegradable Test Fabrics | Use of fabrics made from biodegradable materials for testing durability and performance. | Minimizes environmental impact at the end of the product lifecycle. | 2022 |

| Solar-Powered Testing Equipment | Devices powered by solar energy to conduct various textile tests. | Reduces reliance on non-renewable energy sources. | 2023 |

| Digital Fabric Analysis | Utilization of digital tools and software to analyze fabric properties. | Increases efficiency and reduces material waste during testing. | 2020 |

| Low-Impact Chemical Testing | Testing methods that use non-toxic and low-impact chemicals. | Decreases harmful emissions and waste. | 2022 |

In the textile industry, the integration of Big Data analytics is transforming the landscape of fabric quality assurance. According to a recent report by MarketsandMarkets, the global big data analytics in the textile market is projected to reach $1.82 billion by 2025, growing at a CAGR of 18.2%. This surge is driven by the industry’s need for greater efficiency and precision in quality control processes, enabling manufacturers to anticipate defects and optimize resource allocation.

Data-driven decision-making allows textile companies to analyze vast amounts of data from multiple sources, including production processes, customer feedback, and market trends. By leveraging predictive analytics, manufacturers can identify patterns and insights that inform fabric testing protocols, ensuring that only the highest quality materials make it to market. For instance, the implementation of machine learning algorithms in fabric testing labs has led to a reported 30% reduction in time-to-market for new textile products, as highlighted in the Textile World’s annual performance report. This innovative approach not only enhances product quality but also elevates customer satisfaction by delivering superior fabrics that meet stringent industry standards.

The integration of automation in textile lab equipment has revolutionized the fabric testing landscape, significantly enhancing both efficiency and accuracy. Automated systems allow for the seamless execution of repetitive tasks, which minimizes human error and increases throughput. For instance, automated tensile testing machines can perform multiple tests in quick succession, providing consistent and reliable data that is essential for textile manufacturers aiming to ensure quality control.

Moreover, the application of advanced technologies, such as artificial intelligence and machine learning, is taking textile testing to the next level. These innovations enable labs to analyze vast amounts of testing data rapidly, leading to more informed decision-making. Automated data collection and processing streamline workflows and reduce the time needed for manual interventions. As a result, labs can focus on optimizing their testing protocols, leading to faster product development cycles and enhanced competitiveness in the textile industry. The shift toward automation not only enhances the precision of results but also fosters an environment where innovation can thrive, paving the way for future advancements in fabric testing methodologies.

The textile industry is undergoing a significant transformation, with digitalization emerging as a pivotal force in fabric testing solutions. Traditional methods, often labor-intensive and time-consuming, are being supplanted by innovative digital technologies that enhance efficiency and accuracy. Advanced software and automated equipment streamline the testing process, allowing for real-time analysis and immediate feedback. This shift towards digitization not only improves the precision of tests but also reduces the chances of human error, thus fostering a more reliable production paradigm.

Moreover, the integration of artificial intelligence and machine learning in textile testing is reshaping how the industry approaches quality control. Predictive analytics can forecast potential issues in fabric performance before they arise, enabling manufacturers to make informed adjustments during the production phase. As the industry embraces these digital tools, we can expect a future where textile testing is not only quicker and more efficient but also more aligned with sustainable practices, reducing waste and resource consumption. This evolution signifies a forward-thinking approach, ensuring that the textile industry remains responsive to the challenges of modern consumer demands.