Home

Home

In the realm of packaging and materials science, the accurate measurement of water vapor transmission rates (WVTR) is crucial to ensuring product quality and longevity. A Water Vapor Transmission Tester is essential for assessing how effectively materials can act as barriers against moisture, which is critical for preserving the integrity of packaged goods. As outlined in various industry reports, such as those published by the Packaging Association, improper handling of WVTR can lead to significant losses, both economically and in product efficacy. For instance, the Food Packaging Forum has stated that nearly 30% of food waste can be attributed to inadequate moisture control during packaging. By utilizing a Water Vapor Transmission Tester, manufacturers and researchers can ensure their products meet necessary standards, thus enhancing their reliability in various applications, including food, pharmaceuticals, and electronics. This comprehensive understanding of moisture transmission dynamics is vital for innovation and sustainability within the industry.

Water vapor transmission rates (WVTR) are critical parameters in material testing, playing a pivotal role in determining the suitability of materials for various applications. Industries such as packaging, construction, and textiles rely heavily on these measurements to ensure that materials can adequately resist moisture permeation. High WVTR can lead to product deterioration, compromised structural integrity, and overall performance failure. Understanding these rates allows manufacturers and engineers to choose the right materials that maintain quality and performance over time.

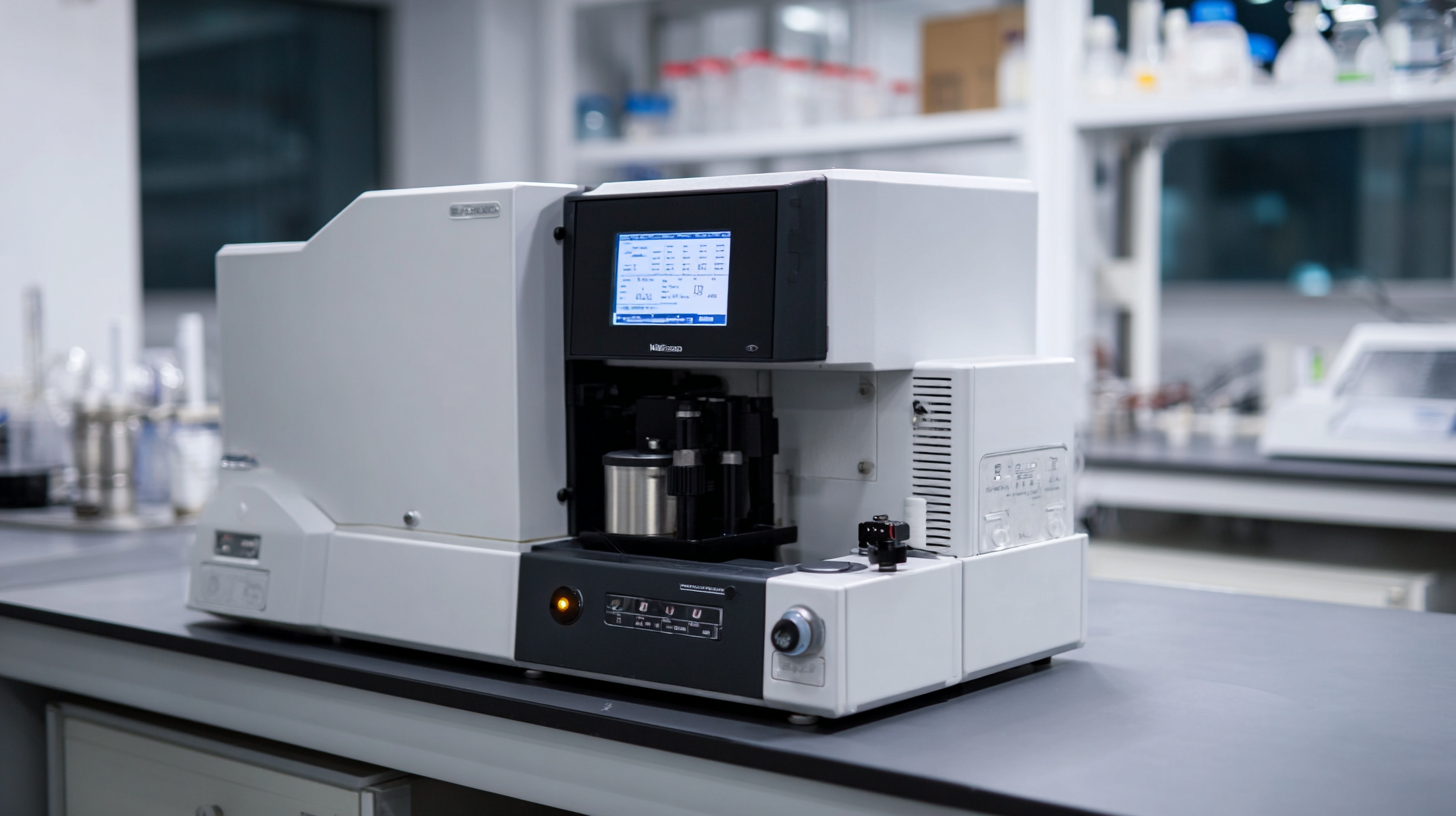

To accurately gauge WVTR, employing a water vapor transmission tester is essential. This equipment simulates environmental conditions to measure how much moisture passes through a material over a specific period. By analyzing the results, professionals can assess which materials offer the best barrier properties against moisture. This is especially important in sectors where maintaining product freshness is paramount, such as food packaging. As such, knowing how to effectively utilize these testing devices ensures that the tested materials meet rigorous industry standards and customer expectations, ultimately contributing to enhanced product reliability and longevity.

This chart represents the water vapor transmission rates of different materials, showcasing how effectively each material allows moisture to pass through. Understanding these rates is crucial for selecting materials in applications requiring moisture control.

When measuring water vapor transmission rates (WVTR) in various materials, several key factors can significantly influence the accuracy and reliability of the results. First, the choice of the material itself plays a crucial role, as different substrates—including polymers, films, and coatings—exhibit varying permeability levels. For instance, certain polymer blends may allow more or less moisture to pass through based on their molecular structure and thickness. Therefore, understanding the specific characteristics of the material being tested is essential to obtain precise measurements.

Additionally, environmental conditions during testing, such as temperature and humidity, can alter the readings substantially. Higher temperatures typically increase the kinetic energy of water molecules, potentially leading to higher transmission rates. Similarly, the relative humidity of both the test environment and the side of the material can create variances in vapor pressure, impacting the rate of water vapor diffusion. Correctly calibrating the testing conditions to match the desired real-world scenario ensures that the measurements reflect actual performance expectations of the material under varying environmental stresses. By paying close attention to these factors, one can achieve more accurate and meaningful water vapor transmission measurements.

When it comes to measuring water vapor transmission, selecting the right tester is crucial for obtaining accurate results. Different applications require specific characteristics from the testing devices. For instance, the ASTM E96 standard outlines methods for determining the water vapor transmission rate (WVTR) of materials, emphasizing the need for an apparatus that aligns with the material properties being measured. A report from the American Society for Testing and Materials indicates that films made from polyolefins may present different vapor transmission characteristics compared to other materials, making it essential to choose a tester specifically designed for the type of substrate in use.

Tips for selecting the appropriate water vapor transmission tester include considering both the material type and the expected environmental conditions. For high barrier materials, testers equipped with sensitive moisture detection technology are recommended. Additionally, understanding the temperature and humidity levels at which your material will be used is vital, as these factors can significantly influence vapor transmission readings. Data from a recent industry survey shows that 60% of testers reported frequent discrepancies in measurements when used outside their optimal conditions, underlining the importance of application-specific choices.

For precise measurements, it's also advisable to consider the sample size and configuration. Some testers function best with larger samples or specific shapes, while others may require smaller samples for enhanced accuracy. Familiarizing yourself with the manufacturer's specifications can help ensure that you're using the correct equipment for your specific application, thereby minimizing errors in your findings.

When preparing samples for water vapor transmission testing, it is essential to ensure that the samples are

representative and properly conditioned. According to a report by the ASTM (American Society for Testing and Materials),

the environmental conditions during sample preparation can significantly affect the results, with humidity and temperature variations leading to discrepancies

in data. Therefore, it is crucial to equilibrate samples in a controlled environment, ideally at 23°C and 50% relative humidity, for at least

24 hours before testing. This process helps to stabilize the moisture content of the materials, ensuring

accurate and reproducible measurements.

Additionally, the thickness and integrity of the sample are critical factors in obtaining reliable results. A comprehensive study published by the

International Journal of Polymer Science highlights that even minor inconsistencies in sample thickness

can result in a variance of up to 20% in water vapor transmission rate (WVTR) measurements. It is recommended

to use standard sample dimensions and to perform visual inspections for any defects that may compromise the testing process. Consistent handling

and preparation methods are paramount to obtaining data that align with industry standards and can be confidently used in product development and

quality assurance.

Interpreting test results from a water vapor transmission tester is crucial for ensuring product quality and regulatory compliance. Accurate data analysis allows manufacturers to determine the barrier properties of materials, a key factor in packaging applications. By assessing the water vapor permeability, companies can make informed decisions regarding material selection and improvements, thereby enhancing product durability and performance.

Moreover, the significance of data accuracy cannot be overstated. When interpreting results, it's vital to consider the influence of environmental conditions during testing, such as temperature and humidity, which can affect measurements. A thorough understanding of these variables, combined with robust calibration and validation processes, helps in achieving reliable results that align with industry standards. This proactive approach not only aids in maintaining compliance but also fosters confidence in product reliability, ultimately benefiting consumers and manufacturers alike.

| Sample ID | Material Type | Thickness (mm) | WVTR (g/m²/day) | Compliance Status |

|---|---|---|---|---|

| 001 | Polyethylene | 0.10 | 3.5 | Pass |

| 002 | Polypropylene | 0.15 | 2.8 | Pass |

| 003 | Nylon | 0.12 | 6.1 | Fail |

| 004 | Polyvinyl Chloride | 0.08 | 1.5 | Pass |

| 005 | Ethylene Vinyl Alcohol | 0.20 | 0.8 | Pass |