Home

Home

In the textile industry, ensuring the quality and durability of fabric is paramount, particularly when it comes to colorfastness. One of the most reliable instruments for this purpose is the Crockmeter Rubbing Fastness Tester. This device meticulously evaluates how well fabrics can withstand friction and abrasion without losing their color. According to Dr. James Anderson, a leading expert in textile testing, "The Crockmeter Rubbing Fastness Tester is essential for providing accurate results that guide manufacturers in producing high-quality textiles."

Implementing the Crockmeter Rubbing Fastness Tester involves a systematic approach that can significantly influence product development and consumer satisfaction. The precision of this testing device helps in identifying potential issues early in the manufacturing process, ensuring that only fabrics that meet stringent quality criteria reach the market. As modern consumers increasingly demand durable and long-lasting products, utilizing this tester plays a critical role in upholding industry standards and enhancing brand reputation.

In conclusion, the Crockmeter Rubbing Fastness Tester is an invaluable tool for fabric testing, enabling manufacturers to guarantee the longevity of their products while simultaneously adhering to quality assurance protocols. Embracing this technology not only improves product quality but also cultivates trust and satisfaction among consumers.

The crockmeter is an essential tool in fabric testing, primarily used to evaluate the color fastness of textiles to rubbing. This process is crucial in determining how well a fabric retains its color when subjected to friction, which occurs during everyday use. Understanding the crockmeter's functionality is vital for manufacturers, retailers, and consumers alike, as it provides insights into the durability of a fabric’s color, ultimately impacting the garment's overall quality and longevity.

In operation, the crockmeter employs a controlled method to simulate the wear and tear that fabrics experience through handling and washing. By rubbing a standardized test cloth against the fabric under specified conditions, users can measure the degree of color transfer that occurs. The results from these tests not only help in assessing compliance with industry standards but also in making informed decisions in the design and production stages. Furthermore, a thorough grasp of the crockmeter and its applications aids in enhancing customer satisfaction, as it enables producers to advertise their products with confidence in their color stability and performance.

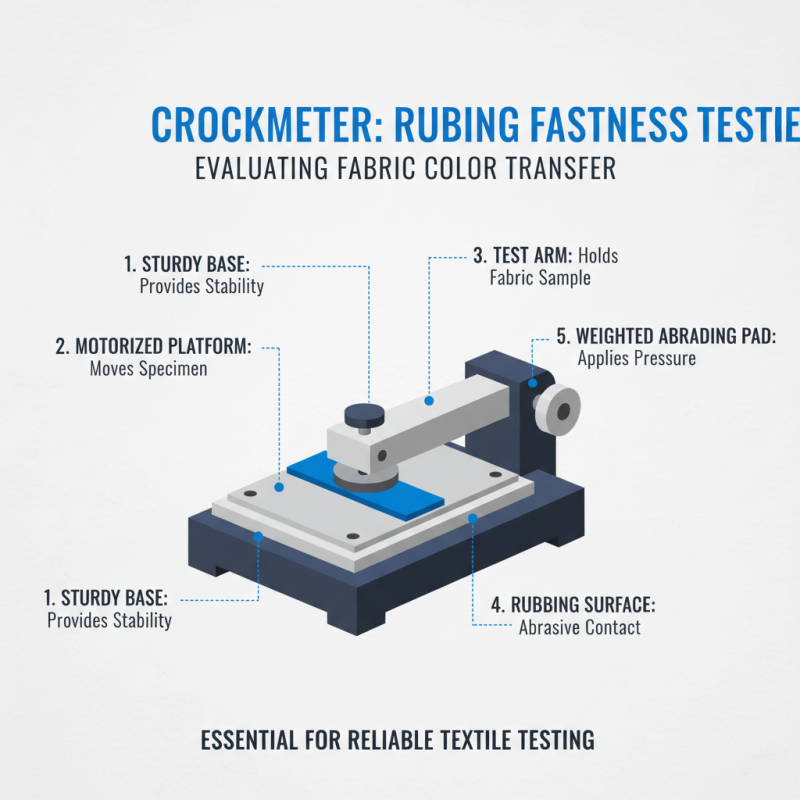

A crockmeter rubbing fastness tester is an essential tool in evaluating the resistance of fabrics to color transfer due to rubbing and abrasion. Understanding its components is crucial for accurate and reliable test results. The primary components of a crockmeter include a sturdy base, a motorized platform, a test arm that holds the specimen, a rubbing surface, and a set of weighted abrading pads. Each component plays a vital role in ensuring that the testing procedure is performed consistently and under controlled conditions.

The motorized platform enables precise control over the test conditions, allowing for a uniform rubbing motion across the fabric. This is crucial because ASTM D5053 standards indicate that variations in pressure and speed can significantly affect the outcome, potentially leading to misinterpretation of fabric quality. The rubbing surface is typically made from a standardized material, which provides a reliable benchmark for assessing color transfer. Furthermore, the weights applied to the abrading pads help simulate real-life wear and tear, which is essential for obtaining results that reflect the fabric's performance in actual use.

In addition, modern crockmeters are often equipped with digital interfaces that allow for detailed data recordings and analysis. According to industry reports, advancements in crockmeter technology have led to a 25% increase in testing efficiency while maintaining accuracy. Utilizing these advanced features can provide valuable insights into fabric performance, ultimately guiding manufacturers and quality control teams in enhancing product durability and customer satisfaction.

Setting up a Crockmeter for fabric testing requires precision and attention to detail to ensure accurate rubbing fastness results. First, begin by selecting the appropriate Crockmeter model suited for your fabric testing needs. According to the American Association of Textile Chemists and Colorists (AATCC), the performance of a Crockmeter should be in compliance with established standards such as AATCC Test Method 8 for colorfastness to rubbing. This method specifies the parameters, including the test specimen size and the type of abradant cloth, which is crucial for generating reliable data.

Next, it's essential to prepare the sample fabric correctly. Cut the fabric into uniform swatches, typically measuring 4 inches by 4 inches. Secure one of these swatches on the Crockmeter platform using clamps, ensuring it is taut without any wrinkles. According to a report from the International Organization for Standardization (ISO), improper sample preparation can lead to variability in results, with discrepancies of up to 20% in color transfer assessments. After securing the sample, calibrate the Crockmeter to apply standard pressure, generally set to 9 pounds, which provides consistent friction during testing. Following these steps meticulously will lead to accurate and reproducible results, ultimately helping manufacturers assess the quality of their fabrics effectively.

When conducting rubbing fastness tests using a crockmeter, it’s essential to follow a structured procedure to ensure accurate and reliable results. The initial step involves preparing the fabric sample to be tested, which should be cut into standard sizes, typically 10 cm x 10 cm, to maintain consistency across tests. This standardization is supported by the American Association of Textile Chemists and Colorists (AATCC), which emphasizes that the sample size can significantly influence the test outcome, potentially skewing results if not adhered to properly.

Once the fabric samples are prepared, mounting them onto the crockmeter is the next critical phase. The crockmeter should be calibrated according to the manufacturer’s specifications to guarantee that the pressure applied during the test is consistent. According to industry reports, such as the ISO 105-X12 guidelines, maintaining a uniform pressure of around 9-12 psi during testing can yield a more accurate assessment of fabric durability against color transfer. Performing multiple tests—commonly at least five replicates per sample—will also help in minimizing variances, providing a more comprehensive understanding of the fabric's performance in real-world conditions.

After the tests are conducted, observers must evaluate the results using standardized gray scales to ensure that the grading is both objective and consistent. The evaluation of color change and dye transfer, when viewed against the gray scales, can give insights into the fabric's robustness. The AATCC reports that fabrics rated above grade 3 generally offer satisfactory rubbing fastness, which is critical information for manufacturers aiming to deliver high-quality textile products. By adhering to these key procedures in rubbing fastness testing, accurate fabric assessment can be achieved, ultimately contributing to ongoing quality assurance in the textile industry.

| Test Sample | Material Type | Testing Method | Number of Rubs | Fastness Grade | Comments |

|---|---|---|---|---|---|

| Sample A | Cotton | Dry Rubbing | 40 | 4 | Acceptable results |

| Sample B | Polyester | Wet Rubbing | 30 | 3 | Minor color loss |

| Sample C | Wool | Dry Rubbing | 50 | 5 | Excellent fastness |

| Sample D | Silk | Wet Rubbing | 20 | 2 | Unsatisfactory |

Using a Crockmeter Rubbing Fastness Tester is pivotal in measuring the durability of fabric under friction. Understanding the test results is essential for manufacturers looking to meet industry standards, such as those set by the American Association of Textile Chemists and Colorists (AATCC), which stipulates that fabrics should resist color transfer to other surfaces. A comprehensive report by Textile World highlights that around 30% of consumer complaints arise from poor color fastening in garments, emphasizing the need for rigorous testing.

Interpreting the results involves assessing multiple factors, including the degree of color change and the transfer onto a white test cloth. A color difference of less than 1.5 on the CIE Lab scale is generally acceptable for high-quality textiles. It's crucial to follow standard testing procedures to avoid inconsistency, as variability can lead to erroneous interpretations. The Shanghai Institute of Textile Science cites that improper calibration of testing instruments can result in a 15% variance in test results, highlighting the importance of regular equipment maintenance.

Tips: Ensure the Crockmeter is calibrated correctly before testing to maintain consistency across batches. Additionally, consider running control tests periodically to gauge the performance of your fabrics accurately. When recording results, document environmental conditions, as humidity and temperature can significantly affect fabric behavior during testing. Such diligence can lead to better quality control and ultimately enhance customer satisfaction.