Home

Home

In the textile industry, ensuring the durability of fabrics against wear and rubbing is crucial for maintaining quality standards. The "Crockmeter Rubbing Fastness Tester" has emerged as an essential tool for evaluating the colorfastness of textiles during abrasion. According to Dr. Lisa Thompson, a renowned expert in textile testing, "Accurate measurement of rubbing fastness not only enhances product quality but also boosts consumer confidence." This underscores the importance of utilizing sophisticated testing methods to achieve reliable results.

Employing a Crockmeter Rubbing Fastness Tester involves specific techniques that can significantly influence the accuracy of the outcomes. By following established protocols and utilizing proper calibration, professionals in the field can minimize variability and improve data integrity. The science behind this testing method lies in its ability to simulate real-world conditions, making it an indispensable instrument in quality control processes across the textile sector.

As we delve deeper into the operational aspects of the Crockmeter Rubbing Fastness Tester, it becomes clear that mastery of this testing equipment is fundamental for manufacturers aiming to meet industry standards. This guide aims to provide insights on best practices for using the Crockmeter, ensuring that users can achieve precise and consistent results in their testing endeavors.

The Crockmeter Rubbing Fastness Tester is a vital instrument in the textile industry, designed to evaluate the colorfastness of fabrics when subjected to rubbing. Proper understanding of this tool is essential, as it plays a crucial role in ensuring product quality and longevity. According to the International Organization for Standardization (ISO), fabrics that pass the crocking test are less likely to transfer color during everyday use, which is essential for customer satisfaction and brand reputation.

When utilizing a Crockmeter, it's important to follow standardized testing procedures. This typically involves placing a specimen of the test fabric and a white test cloth. The testing machine then rubs the two surfaces together under standardized pressure. Data from the American Society for Testing and Materials (ASTM) highlights that 85% of color transfer occurs during the first few rubs, emphasizing the need for accurate initial readings.

Tips for effective testing: Always ensure that the test fabric is clean and free from any contaminants that could skew results. Regularly calibrate the Crockmeter to maintain accuracy across different batches. Lastly, document environmental conditions such as humidity and temperature, as they can alter the fabric's performance during testing. Following these guidelines will help achieve reliable and reproducible results, ultimately improving the quality of textile products.

A crockmeter rubbing fastness tester is an essential tool in evaluating the colorfastness of textiles, specifically how well a material can withstand rubbing. The key components of a crockmeter include a weighted arm, a color transfer cloth, and a mounting surface for the sample. The weighted arm applies a predetermined pressure, typically ranging from 9 to 12 pounds, on the fabric, which simulates the wear and tear that textiles undergo in real-life applications. According to industry reports, approximately 15% of textile defects arise from inadequate colorfastness, emphasizing the importance of accurate testing to prevent costly returns and maintain quality standards.

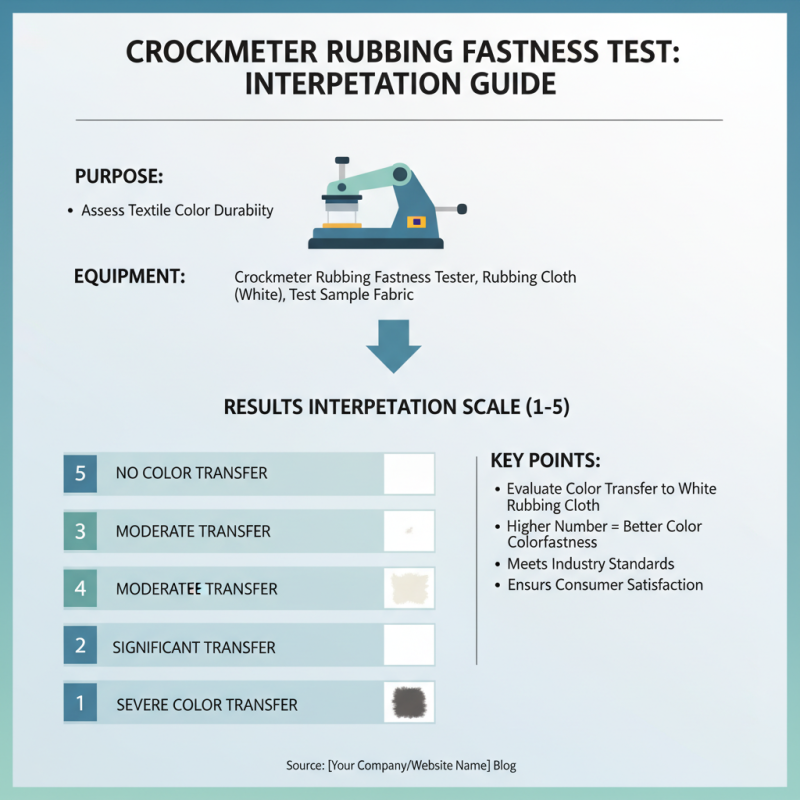

The design of the crockmeter allows for controlled testing conditions. The color transfer cloth, usually made from white cotton, is used to assess the degree of color transfer from the test fabric during the rubbing process. Results are evaluated based on a grayscale scale of 1 to 5, with 1 indicating significant color transfer and 5 indicating no transfer. In recent studies, textiles that scored below 3 were found to have an elevated risk of dissatisfaction among consumers, underscoring the necessity for manufacturers to prioritize accurate assessment using crockmeters. Overall, the integration of a crockmeter into quality control processes not only enhances the reliability of textile products but also aligns with industry standards set by organizations such as ASTM International.

Setting up a crockmeter for testing is crucial to ensure accurate results in assessing the rubbing fastness of textiles. Start by placing the fabric sample securely on the testing platform, ensuring no creases or interfaces that could affect the outcome. According to the American Association of Textile Chemists and Colorists (AATCC), proper alignment is critical as misalignment can lead to significant variations in rub-off results—up to 40% in some cases. Use the adjustable clamps to firmly hold the fabric in place and eliminate any movement during the test.

Next, configure the settings on the crockmeter to meet the specific requirements of your testing standards. The AATCC specifies that the choice of rubbing surface and the pressure applied can dramatically influence the results. For example, using a standardized white cloth as the rubbing surface helps maintain consistency across tests. Additionally, always ensure the weight of the test arm is set according to the relevant testing protocols. Adhering strictly to these guidelines not only minimizes variability but also enhances the reliability of the test outcomes, which is essential for quality control in textile manufacturing, where an estimated 30% of customer complaints stem from issues related to color fastness.

Executing the rubbing fastness test is a crucial process that ensures the color and quality of textiles meet industry standards. Begin by preparing the test sample: cut a piece of fabric, ensuring it is free from any contaminants or stains that may affect results. Position the sample securely on the testing platform, and select an appropriate rubbing surface, typically a standardized cloth or paper. This ensures consistency across different tests.

Next, the tester sets the weight and lateral motion parameters on the crockmeter. It’s essential to maintain a consistent pressure and speed while rub-testing the fabric to derive accurate and reproducible results. After executing the specified number of rubs, carefully assess the samples for color transfer and fading. Document the findings meticulously, comparing the degree of staining on the test fabric to established color fastness standards. By following these detailed procedures and techniques, accurate assessments of fabric durability can be achieved, aiding in the production of high-quality textiles.

| Parameter | Description | Typical Values | Measurement Method |

|---|---|---|---|

| Test Material | Type of fabric being tested | Cotton, Polyester, Wool | Visual Identification |

| Test Conditions | Humidity and temperature settings during the test | 65% RH, 20°C | Standard Lab Conditions |

| Rubbing Pressure | Pressure applied during rubbing | 9N, 12N | Using Weighted Arm |

| Rubbing Cycles | Number of times the fabric is rubbed | 10, 20, 30 | Manual or Automatic Setting |

| Color Change | Degree of color change post test | Grade 1 to Grade 5 | Color Fastness Scale |

| Transfer of Color | Amount of color transferred to a white cloth | Grade 1 to Grade 5 | Visual Comparison |

When using a crockmeter rubbing fastness tester, accurate interpretation of results is crucial for assessing the durability of textiles. After conducting the test, it is essential to evaluate the color transfer from the test sample to the rubbing cloth. This is typically rated on a scale from 1 to 5, with 5 indicating no transfer and 1 denoting significant color loss. Understanding this scale allows for a consistent assessment of fabric quality, enabling manufacturers to meet industry standards and consumer expectations.

Ensuring accurate measurements begins with proper calibration of the crockmeter. Regular calibration checks guarantee that the equipment provides reliable data. It is also important to use the correct rubbing cloth that matches specific testing protocols, as variations can lead to misleading results. Additionally, environmental factors such as humidity and temperature should be monitored, as these can significantly impact durability outcomes. By maintaining strict control over these variables and following standardized procedures, testers can achieve precise and repeatable results that accurately reflect the performance of the materials being evaluated.