Home

Home

In today's fast-paced industrial landscape, selecting the appropriate Wrap Reel Electronic is crucial for optimizing operational efficiency and productivity. According to a recent report by Smithers Pira, the global demand for automated packaging solutions is projected to grow by over 10% annually, underscoring the significant role of advanced wrapping technologies in streamlining processes. Businesses that leverage effective wrap reel systems can expect to reduce material waste by up to 30% while enhancing throughput and reducing labor costs. As the market increasingly trends towards automation and sustainable practices, understanding the specific needs of your operations and the various features of wrap reel electronic devices becomes essential. This guide aims to elucidate the critical factors to consider when choosing the right wrap reel electronic tailored to your business requirements, ensuring that you remain competitive in a rapidly evolving market.

In today's fast-paced industrial landscape, selecting the appropriate Wrap Reel Electronic is crucial for optimizing operational efficiency and productivity. According to a recent report by Smithers Pira, the global demand for automated packaging solutions is projected to grow by over 10% annually, underscoring the significant role of advanced wrapping technologies in streamlining processes. Businesses that leverage effective wrap reel systems can expect to reduce material waste by up to 30% while enhancing throughput and reducing labor costs. As the market increasingly trends towards automation and sustainable practices, understanding the specific needs of your operations and the various features of wrap reel electronic devices becomes essential. This guide aims to elucidate the critical factors to consider when choosing the right wrap reel electronic tailored to your business requirements, ensuring that you remain competitive in a rapidly evolving market.

When selecting a wrap reel electronic for your business, there are several key factors to consider that can greatly influence your operational efficiency and cost-effectiveness. First and foremost, assess the volume of products you need to wrap. If your business handles high volumes, a high-speed wrap reel with automated features may be necessary to keep up with demand. On the other hand, a smaller operation may benefit from a manual or semi-automatic reel that offers versatility without the need for significant investment.

Another crucial factor is the type of materials you will be wrapping. Different electronic wrap reels are designed to work with various materials, including stretch film, shrink wrap, or padding. Ensure that the reel you choose can accommodate the specific materials your business uses, as this will directly affect both the quality of packaging and overall efficiency.

Tip: When considering wrap reel options, look for models that offer adjustable tensions and widths. This adaptability can enhance the wrapping process and reduce waste, allowing you to tailor the machine's performance to your unique packaging needs. Additionally, investing in a wrap reel with user-friendly controls can simplify training for your staff and minimize operational errors.

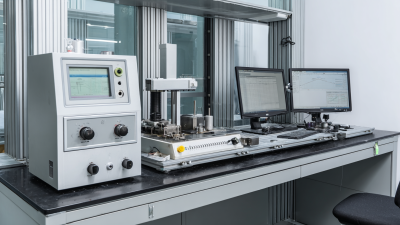

When selecting the right wrap reel electronic for your business, it’s essential to understand the variety of options available in the market. Wrap reel electronics come in different types, each designed for specific applications. Manual wrap reel options are cost-effective and suitable for smaller operations, whereas automatic models increase efficiency and reduce labor costs for larger businesses. Additionally, semi-automatic reels provide a balance between control and automation, making them ideal for mid-sized operations.

**Tip:** Consider the volume of work your business handles daily. If you have high throughput, investing in an automatic wrap reel can save time and resources in the long run.

Another important factor to consider is the material compatibility with the wrap reel. Some wrap reel electronics are designed specifically for stretch film, while others can accommodate a variety of materials, such as shrink film or pallet wraps. Understanding your packaging needs will help in selecting the right model that enhances productivity without compromising on quality.

**Tip:** Evaluate the size and weight capacity of the wrap reel to ensure it meets your specific product requirements. This consideration is crucial to maintain efficiency and avoid any damage during the wrapping process.

When selecting a wrap reel electronic for your business, it's essential first to assess your specific operational needs. Consider the types of products you are handling. Are they small and lightweight, or larger and heavier? This determines the size and capacity of the wrap reel you require. Additionally, evaluate the frequency with which you will use the reel. If your business has a high volume of packaging, opting for a model that offers increased durability and speed can enhance productivity.

Another critical factor to consider is the functionality you need. Some wrap reel electronics come equipped with advanced features, such as automatic tension control and programmable settings, which can significantly improve efficiency. Also, think about the workspace layout—will the reel need to fit in a tight area, or do you have ample space for a larger unit? By taking the time to analyze these specific aspects, you can choose a wrap reel electronic that not only meets your current demands but also scales with your business growth in the long run.

When choosing the right wrap reel electronic for your business, evaluating durability and performance features is crucial. Durability often dictates the lifespan and reliability of the equipment, especially in environments where heavy use is common. Look for models constructed with high-quality materials that can withstand wear and tear. Additionally, consider units with protective features such as weather resistance or reinforced housing to ensure they perform optimally over time.

Performance features are equally vital in ensuring efficiency and productivity. Assessing the speed, power output, and ease of use can greatly affect workflow. For instance, some wrap reel electronics come with adjustable speed settings, which can be beneficial for different types of wrapping projects. It’s also wise to explore options that include automatic functionalities, as these can save valuable time and reduce manual labor.

Tips for selecting the best wrap reel electronics include checking for warranty options and customer reviews to gauge reliability. Also, test the unit in a demonstration, if possible, to ensure it meets your specific operational requirements. Investing time in identifying the right features will ultimately enhance your wrapping processes and support your business needs.

When selecting a wrap reel electronic for your business, cost-effectiveness is a critical factor to consider. According to a recent industry report by Grand View Research, the global market for wrapping machines is expected to reach $6.05 billion by 2025, indicating a robust demand for efficient packaging solutions. Different models of wrap reel electronics vary significantly in price and performance features. For example, semi-automatic wrap reels can start around $2,000, while fully automatic models may exceed $10,000.

Evaluating the total cost of ownership is key when comparing models. A study by Packaging Strategies highlights that investing in a higher-quality wrap reel can reduce material waste and labor costs, ultimately delivering a better return on investment. Businesses that opt for durable, high-capacity machines often report a 20-30% increase in productivity, underscoring the importance of considering long-term benefits rather than just initial pricing. By carefully assessing these factors, companies can ensure they make informed decisions that align with their operational needs and financial goals.