Home

Home

In the world of material testing, choosing the right Friction Coefficient Tester is crucial. Dr. Emily Chen, a renowned expert in tribology, once stated, "Selecting the right tester is the foundation of accurate results." Her insights highlight the importance of this decision.

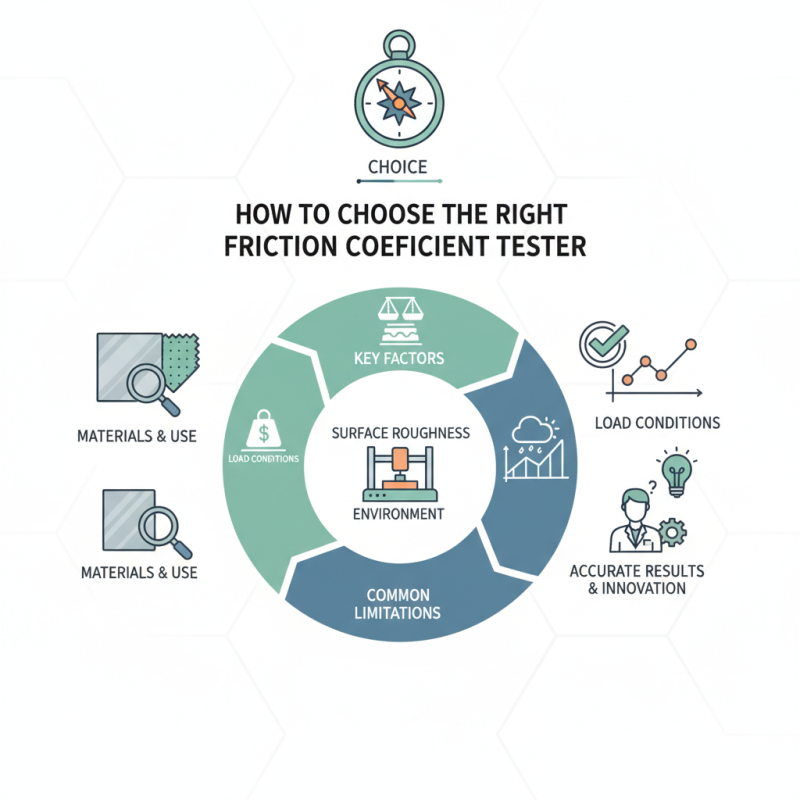

Friction Coefficient Testers come in various forms, each designed for specific applications. A good selection relies heavily on understanding the materials involved and their intended use. Factors like surface roughness, load conditions, and environmental influences cannot be ignored.

Many testers, however, have limitations. Some devices may not provide consistent results under varying conditions. Users often face challenges in obtaining reliable data. Recognizing these flaws is essential for improvement. Choosing the right Friction Coefficient Tester is a step towards better material analysis and innovation.

Friction coefficient testers are essential tools in material testing. They assess how different surfaces interact. Understanding their functionality helps in choosing the right model for your needs.

According to industry reports, the friction coefficient can significantly impact material performance. For instance, a high friction coefficient can lead to increased wear and tear. Conversely, a low coefficient may reduce traction, causing safety concerns. In automotive applications, optimal friction levels are crucial for tire performance and stability. Some tests show a variance in friction coefficients could reach up to 0.50 on different surfaces.

When selecting a tester, consider the environment. Different materials react differently under varied conditions. Temperature, humidity, and surface roughness all play a part. A study revealed that about 30% of friction testing results were influenced by environmental conditions. Thus, ensuring your tester is adaptable is vital. Look for a model that provides precise readings, accounting for these variables. Testing should be a balanced mix of accuracy and practicality.

Choosing the right friction coefficient tester is crucial for accurate results. One important factor to consider is the testing method. Different methods yield varying outcomes based on the materials involved. For instance, a drag test might show different results compared to a static test. Evaluating which method fits your needs is essential.

Another key aspect is the range of materials the tester can evaluate. You want a machine that can handle diverse surfaces. Some testers may struggle with certain materials, leading to unreliable data. This inconsistency can hinder quality control. It’s wise to think about the materials you will most frequently test. This decision will save time and resources.

Moreover, user-friendliness is often overlooked. Complex machinery can lead to errors. Operators must understand how to use the device correctly. A poorly designed interface may result in mistakes. Therefore, assess whether the tester provides clear guidance. This consideration should not be ignored if you aim for precision in your tests.

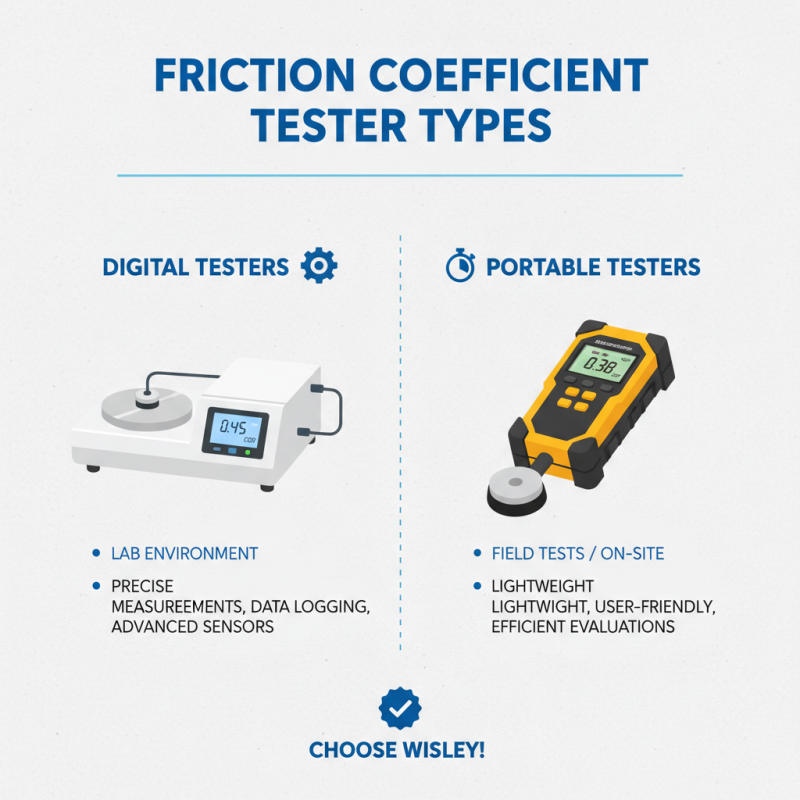

When selecting a friction coefficient tester, it’s essential to understand the various types available. Each type caters to specific requirements and applications. For instance, digital testers offer precise measurements for lab environments. They feature advanced sensors and data logging capabilities. Meanwhile, portable testers are suitable for field tests. These devices are lightweight and user-friendly, making on-site evaluations efficient.

Consider the method of friction measurement. Some testers focus on static friction, while others assess dynamic friction. The choice depends on your industry needs. For example, automotive applications often require dynamic friction tests. In contrast, packaging industries may prioritize static testing. Always check compatibility with your materials and conditions.

Tips: Look for testers that are easy to calibrate. Regular calibration maintains accuracy. Also, think about future needs. Will you need to test different materials later? Choose a versatile tester to accommodate various surfaces. Price may impact your choice, but quality shouldn’t be compromised. Poorly chosen equipment can lead to misleading results.

When selecting a friction coefficient tester, assessing its accuracy is crucial. Accurate measurements ensure that the results align with real-world conditions. Look for devices that offer consistent readings. Variations in results may indicate calibration issues. Those discrepancies can impact research or production decisions. Thus, choosing wisely is essential.

Reliability is equally important. A reliable tester should function well under varied conditions. Temperature and humidity can influence outcomes. Testing devices should maintain performance across different environments. Regular maintenance and verification of the equipment help ensure reliability. Analytical comparisons may reveal weaknesses in performance.

It's vital to understand the limitations of the chosen tester. No device is flawless. Each tester has a range of optimal conditions. You might encounter unexpected results. This emphasizes the need for thorough evaluation. Balancing accuracy and reliability can be challenging. Adaptability is key in friction testing.

When selecting a friction coefficient tester, budget plays a critical role. A high-quality tester can range from a few hundred to several thousand dollars. According to industry reports, investing in reliable equipment can enhance the accuracy of results, which, in turn, impacts product safety and performance.

For example, a basic tester may provide limited functionality. However, advanced models offer features like digital displays and automated test cycles. These enhancements can significantly improve testing efficiency, but come at a cost. It’s essential to evaluate whether the additional features justify the price difference. Consider how frequently the tester will be used. A one-time project may not warrant a high investment.

**Tips:** Be mindful of hidden costs. Calibration and maintenance add to long-term expenses. Additionally, user training may be necessary for complex devices. It’s easy to overlook these factors during the purchasing process. Sometimes, cheaper alternatives can deliver acceptable results, depending on your needs.

Seeking out user reviews and industry comparisons can guide your decision. Sometimes, it might be wise to rent equipment for short-term needs. This approach can save money while allowing you to test the waters before making a purchase.

| Tester Type | Price Range | Accuracy | Material Compatibility | User Level |

|---|---|---|---|---|

| Portable Friction Tester | $500 - $1,000 | ±0.01 | Rubber, Plastic | Beginner |

| Digital Friction Tester | $1,200 - $2,500 | ±0.05 | Metal, Wood | Intermediate |

| Industrial Friction Tester | $3,000 - $5,000 | ±0.01 | All Materials | Advanced |

| Surface Friction Tester | $800 - $1,800 | ±0.02 | Concrete, Asphalt | All Levels |