Home

Home

When it comes to maintaining standards in the textile industry, the importance of reliable and accurate Textile Laboratory Testing Equipment cannot be overstated. The performance and quality of textiles are gauged through various tests that assess factors such as durability, colorfastness, and safety. However, with a plethora of options available on the market, selecting the right equipment tailored to your specific needs can be a daunting task. This guide aims to ease that decision-making process by outlining key factors to consider to ensure the optimal choice in testing equipment.

The complexity of textile testing necessitates a clear understanding of the types of tests required and the standards that must be met. Factors such as the types of materials being tested, the expected volume of testing, and compliance with industry benchmarks play a crucial role in determining the most suitable Textile Laboratory Testing Equipment. Additionally, it's essential to consider the equipment's ease of use, maintenance requirements, and the level of support provided by suppliers. Ultimately, choosing appropriate testing equipment not only enhances the accuracy of results but also contributes to the overall efficiency and credibility of your textile operations.

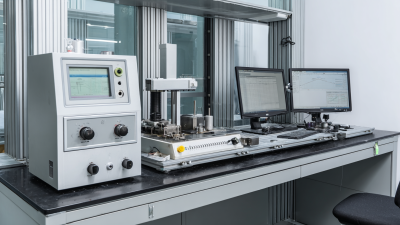

When selecting textile laboratory testing equipment, it is crucial to understand the different types available to ensure they meet your specific needs. One primary category includes physical testing equipment, which evaluates properties such as tensile strength, tear strength, and abrasion resistance. Devices such as universal testing machines and abrasion testers provide essential data to assess the durability and overall quality of textiles.

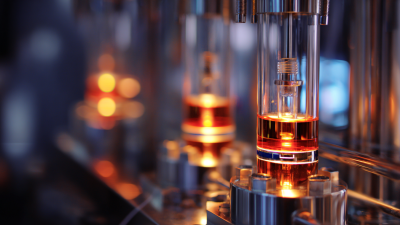

Another important category is chemical testing equipment, which focuses on analyzing the fabric's composition and chemical properties. This includes equipment like spectrophotometers and gas chromatography systems that help identify dyes, finishes, and contaminants in textiles. Additionally, environmental testing apparatus, such as weathering chambers and moisture meters, assess how textiles perform under various environmental conditions. Each type of testing equipment addresses different aspects of textile performance, aiding manufacturers and researchers in developing high-quality, compliant products.

When selecting textile laboratory testing equipment, several key factors should be taken into account to ensure that the instruments meet your specific needs. First, consider the type of tests you will be conducting. Different textiles may require different testing parameters, such as strength, durability, color fastness, and moisture management. Understanding the requirements of your products and the industry standards is essential in determining which testing equipment will be most effective for your applications.

Another important factor is the precision and accuracy of the equipment. High-quality testing instruments provide reliable results, allowing you to make informed decisions about material quality and performance. It's vital to look for devices that come with certifications or adhere to recognized testing standards, as this ensures their credibility in producing consistent and reproducible data. Additionally, evaluate the ease of use and maintenance of the equipment. User-friendly technology can streamline laboratory processes, while well-maintained instruments contribute to longevity and operational efficiency.

When selecting textile laboratory testing equipment, a thorough understanding of industry standards and compliance is pivotal. The International Organization for Standardization (ISO) provides a comprehensive framework for textile testing, establishing critical benchmarks that ensure products meet safety and quality requirements. For instance, ISO 105 categorizes tests by color fastness to various agents, such as light and washing, with compliance requirements guiding laboratories in developing methods that yield reproducible results. Adhering to these guidelines helps manufacturers demonstrate compliance with regulations while ensuring product integrity.

Moreover, various reports emphasize that the global textile testing market is projected to grow significantly, driven by increasing consumer demand for high-quality and safely manufactured products. According to a report by Research and Markets, the textile testing market size was valued at approximately USD 3.57 billion in 2020, and it is anticipated to expand at a compound annual growth rate (CAGR) of about 7.3% from 2021 to 2028. This growth underscores the importance of comprehensive testing protocols, not only to meet regulatory demands but also to maintain competitive advantage in an increasingly quality-sensitive market. Investing in state-of-the-art testing equipment that adheres to these industry standards is crucial for manufacturers aiming to ensure compliance and enhance their product offerings.

When selecting textile laboratory testing equipment, evaluating the accuracy and precision of the devices is crucial. Accuracy refers to how close a measurement is to the true value, while precision reflects the consistency of results when the same test is repeated. Ensuring that the equipment offers both high accuracy and precision helps laboratories achieve reliable results, which are essential for quality control and compliance with industry standards.

One way to assess the accuracy of textile testing devices is by conducting calibration checks with known standards. Devices should be regularly calibrated to maintain their accuracy over time. Additionally, reviewing the manufacturer's specifications regarding measurement uncertainty can provide insight into the reliability of the equipment. When considering precision, consistent test conditions are important, as variations in temperature, humidity, and sample handling can affect outcomes. Testing laboratories should implement rigorous protocols to minimize these variables, thus improving the repeatability of their results.

Furthermore, it's beneficial to look for equipment that offers user-friendly interfaces and comprehensive data analysis capabilities. This helps technicians not only to operate the instruments effectively but also to monitor and record statistical data that reflects the accuracy and precision of testing processes. Investing in quality equipment that offers both accurate and precise measurements will ultimately enhance the credibility and efficacy of laboratory testing in the textile industry.

When budgeting for textile laboratory equipment, it’s essential to consider not only the initial purchase cost but also the potential return on investment (ROI). The global textile testing equipment market is projected to grow at a CAGR of approximately 5.2% from 2021 to 2026, highlighting the increasing importance of quality control in the textile industry. Investing in reliable testing equipment can significantly enhance product quality, ensuring compliance with industry standards and reducing the risk of costly recalls. According to the Textile World industry report, the average cost of improper testing can lead to losses upwards of 20% of annual revenues, making a clear case for investing wisely.

Tips for budgeting effectively include assessing the specific testing needs of your facility. Prioritize equipment that meets both regulatory requirements and your company’s standards. Engage with industry reports and studies to identify trends in testing technology that can provide long-term savings. Additionally, consider partnering with suppliers that offer maintenance and support services as part of the package, which can further protect your investment and enhance operational efficiency.

Moreover, calculate potential ROI by considering factors such as increased production efficiency, reduced waste, and improved customer satisfaction from higher quality products. Investing in textile laboratory testing equipment not only fortifies your production process but also positions your company as a leader in quality assurance, ensuring long-term profitability in a competitive market.