Home

Home

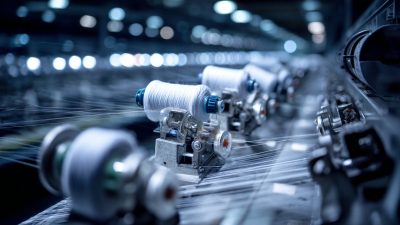

In the ever-evolving textile industry, ensuring the quality and durability of fabrics is paramount. This is where a Textile Testing Machine becomes an essential tool for manufacturers and quality assurance professionals. These sophisticated machines are designed to evaluate various properties of textiles, including tensile strength, color fastness, and fabric abrasiveness. With the increasing demand for high-quality textiles, investing in reliable testing equipment is crucial for maintaining competitiveness in the market.

This article presents the 10 best Textile Testing Machines that excel in performance, reliability, and user-friendliness. We delve into the unique features and capabilities of each machine, ensuring that everyone from small textile businesses to large manufacturers can find the right fit for their quality assurance needs. Additionally, we provide tips on what to look for when selecting a testing machine, empowering readers to make informed decisions that align with their specific requirements. By prioritizing quality assurance through advanced textile testing, businesses can guarantee customer satisfaction and uphold their reputation in the textile landscape.

Textile testing machines are essential tools in ensuring the quality and reliability of fabrics in the textile industry. Advanced textile testing machines come equipped with a range of key features that enhance their capability to deliver precise and consistent results. For instance, many of these machines include automated measurement systems, which not only streamline the testing process but also reduce human error. This technology allows for rapid assessments of fabric strength, durability, and other critical quality parameters, ensuring that manufacturers can maintain high standards.

Another significant feature of modern textile testing machines is their integration with advanced software that provides in-depth data analysis and reporting. This software often includes customizable testing protocols that cater to specific fabric types and industry standards, making it easier for textile manufacturers to achieve compliance. Additionally, real-time monitoring capabilities enable operators to track performance metrics continuously, further enhancing quality assurance processes. Overall, these advanced features contribute significantly to the effectiveness of textile testing machines in achieving reliable quality assurance in the competitive textile market.

In the textile industry, ensuring high quality is paramount, and accuracy in testing is a crucial component of quality assurance. Accurate textile testing helps manufacturers identify potential defects early in the production process, minimizing waste and reducing costs. By using advanced textile testing machines, companies can obtain reliable data on various fabric properties, such as strength, durability, and colorfastness. This data not only aids in compliance with industry standards but also enhances customer satisfaction by ensuring that products meet their expectations.

Moreover, accurate testing contributes to the overall reputation of a brand. In an increasingly competitive market, consumers are becoming more discerning, prioritizing quality over price. If a textile product fails to meet expected standards, it can lead to negative reviews and a loss of customer trust. Therefore, investing in state-of-the-art testing machines is essential for textile manufacturers who aim for consistency and excellence in their products. High-precision testing not only safeguards the integrity of each batch but also fosters innovation and continual improvement, ultimately driving business success.

Advancements in textile testing equipment are crucial for enhancing quality assurance processes in the textile industry. Innovative technologies such as digital imaging, automation, and real-time data analysis have significantly improved the accuracy and efficiency of textile testing. For instance, digital imaging systems offer precise measurements of fabric properties, ensuring consistency and reliability in production. Meanwhile, automated testing machines reduce human error and increase testing speed, allowing manufacturers to meet market demands more effectively.

Tips for optimizing your textile testing process include regularly updating your testing machinery to incorporate the latest technologies. Emphasizing calibration and maintenance of equipment can greatly impact the accuracy of your results. Additionally, investing in staff training on the latest testing methods will ensure that your team maximizes the potential of advanced technologies.

By adopting these innovative technologies and tips, companies can enhance their textile testing procedures, ensuring that products meet international quality standards and consumer expectations. This not only boosts brand reputation but also drives business growth through improved customer satisfaction.

When it comes to textile testing solutions, selecting the right equipment is crucial for ensuring product quality and compliance with industry standards. Leading brands in the market offer a range of machines that cater to various testing needs, from tensile strength to colorfastness, each with its own set of features and advantages. Companies such as Instron and SDL Atlas have established themselves as front-runners by integrating advanced technology, ensuring precision and reliability in their testing processes.

Another notable brand is Uster Technologies, known for its innovative solutions that provide a comprehensive analysis of fabric properties. Their machines are designed to meet the challenges of modern textile manufacturing while ensuring that the end products meet stringent quality requirements. Moreover, brands like Martindale and Shirley offer specialized testing machines that focus on specific metrics, allowing users to conduct thorough assessments tailored to their production needs. By comparing these leading brands, manufacturers can make informed decisions that enhance their quality assurance protocols and contribute to overall efficiency in production.

| Testing Machine | Testing Type | Capacity | Accuracy | Price Range ($) |

|---|---|---|---|---|

| Tensile Tester | Tensile Strength | 5 kN | ±0.5% | 1500 - 2500 |

| Bursting Strength Tester | Burst Strength | 20 kPa | ±1% | 1200 - 2000 |

| Color Fastness Tester | Color Fastness | N/A | ±0.2 | 800 - 1500 |

| Friction Tester | Friction Coefficient | 5 kg | ±0.1 | 400 - 1000 |

| Thickness Gauge | Fabric Thickness | 0 - 10 mm | ±0.01 mm | 300 - 700 |

As the textile industry continues to evolve, the development of testing machines plays a crucial role in ensuring quality assurance. One of the key future trends is the integration of automation and artificial intelligence in textile testing processes. According to a recent industry report by MarketsandMarkets, the textile testing equipment market is expected to grow from USD 2.2 billion in 2022 to USD 3.1 billion by 2027, driven by advancements in technology and the increasing demand for high-quality textiles. Automated systems not only reduce human error but also enhance efficiency, allowing for real-time data collection and analysis.

Moreover, sustainability is becoming a significant focus in textile testing. Manufacturers are now prioritizing eco-friendly testing solutions that minimize waste and environmental impact. It is estimated that sustainable testing methods can reduce resource consumption by up to 30%, as highlighted in a study by the Global Sustainable Textile Coalition. This shift not only addresses environmental concerns but also aligns with consumer preferences for responsible production practices.

Tips: When choosing a textile testing machine, consider models that offer advanced automation and AI features to stay ahead of industry trends. Additionally, look for equipment that embraces sustainable practices to meet the growing demand for environmentally friendly textiles. Regularly update your testing protocols to incorporate emerging technologies, ensuring your quality assurance processes remain robust and relevant.