Home

Home

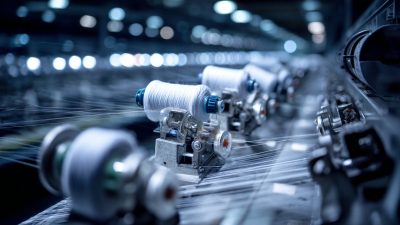

In the highly competitive textile industry, ensuring the quality and longevity of fabrics is paramount. Industry experts underscore the importance of rigorous testing methods to maintain high standards, and one such vital tool is the Crockmeter Rubbing Fastness Tester. According to Dr. Emily Carter, a leading authority in textile testing, "The Crockmeter Rubbing Fastness Tester not only provides accurate results for color transfer but also empowers manufacturers to uphold their commitment to quality."

The use of a Crockmeter Rubbing Fastness Tester is instrumental in assessing the durability of fabrics against rubbing and friction, a common challenge faced by manufacturers. This essential testing equipment serves as a benchmark for quality control, enabling businesses to make informed decisions and improve their product offerings. As we explore the top ten benefits of employing this tester in quality control processes, it becomes evident that investing in the Crockmeter Rubbing Fastness Tester is crucial for any textile company aiming to enhance product performance and customer satisfaction.

By incorporating the insights gained from this powerful testing apparatus, manufacturers can not only safeguard their reputation but also foster innovation in fabric design and construction. In a market that increasingly demands resilience and colorfastness, the Crockmeter Rubbing Fastness Tester stands out as an indispensable resource for quality assurance.

The crockmeter rubbing fastness tester plays a crucial role in evaluating color retention in various materials, especially textiles. By simulating wear and friction that fabrics experience during use, this testing method provides valuable insights into the durability of colors. According to a report by the American Association of Textile Chemists and Colorists (AATCC), nearly 50% of color fading in garments occurs due to abrasion. Utilizing a crockmeter allows manufacturers to predict how well their products will maintain color integrity over time, thereby enhancing overall quality control.

Furthermore, the use of crockmeter testing can significantly reduce returns and complaints due to color inconsistencies. A study published in the Journal of the Textile Institute noted that implementing rigorous rubbing fastness testing reduced customer returns by up to 30% for major apparel brands. As consumer awareness grows around fabric quality and longevity, brands that prioritize effective color retention evaluations through crockmeter testing are better positioned to meet market demands and improve customer satisfaction. This testing not only serves as an industry standard but also strengthens the reputation of manufacturers committed to quality.

In the textile manufacturing industry, maintaining high-quality standards is crucial for ensuring the durability and longevity of fabric products. The use of a Crockmeter Rubbing Fastness Tester plays a pivotal role in achieving enhanced quality control standards. According to a report by the International Organization for Standardization (ISO), about 25% of textile defects can be attributed to poor color fastness. A Crockmeter allows manufacturers to accurately assess color transfer that occurs through rubbing, ensuring that the end product meets consumer expectations and industry regulations.

Employing a Crockmeter not only helps identify potential issues in color durability but also enhances a manufacturer's credibility. Studies indicate that brands with robust quality control practices experience 30% fewer product returns, significantly reducing costs associated with warranty claims and improving customer satisfaction. By incorporating this testing tool, textile manufacturers can ensure consistent quality, leading to improved market reputation and increased sales potential in a competitive landscape.

As consumers become more discerning about the products they use, the importance of thorough quality control cannot be overstated, making the Crockmeter an essential investment for industry players aiming to excel.

In today's competitive market, ensuring that textiles meet industry regulations and specifications is crucial for manufacturers. The Crockmeter Rubbing Fastness Tester serves as an invaluable tool in achieving streamlined compliance. By accurately assessing the colorfastness of fabrics when subjected to abrasion, this instrument helps manufacturers address potential quality issues before products reach the consumer. This proactive approach not only minimizes the risk of non-compliance but also enhances brand reputation by ensuring that products meet or exceed industry standards.

Moreover, utilizing a Crockmeter enables manufacturers to save time and resources in quality control processes. Automated testing provides quick and reliable results, allowing teams to make informed decisions rapidly. This efficiency reduces the cycle time from testing to market, enabling companies to respond swiftly to consumer demands and regulatory changes. Thus, implementing a Crockmeter is not just about compliance; it represents a significant leap towards operational excellence in the textile industry.

| Benefit | Description | Impact on Quality Control |

|---|---|---|

| Accurate Fastness Measurement | Provides precise readings to assess fabric durability. | Ensures products meet durability standards. |

| Streamlined Testing Process | Simplifies the procedure for testing fabric resistance. | Reduces time and labor costs in testing. |

| Standardized Testing Conditions | Maintains consistent conditions across tests. | Enhances reliability of test results. |

| Regulatory Compliance | Helps meet industry standards and regulations. | Ensures products are market-ready. |

| Quality Assurance | Ensures that fabrics maintain color and integrity. | Minimizes the risk of customer complaints. |

| Cost-Effectiveness | Reduces waste and rework by identifying issues early. | Improves overall profitability. |

| Enhanced Customer Satisfaction | Delivers high-quality products that meet expectations. | Fosters brand loyalty and repeat business. |

| Data-Driven Insights | Provides valuable data for process improvements. | Facilitates better decision-making. |

| Flexibility in Testing | Supports various fabric types and finishes. | Accommodates diverse product lines. |

| Improved Product Development | Facilitates innovation by testing new materials. | Supports cutting-edge fabric technologies. |

The Crockmeter rubbing fastness tester is a crucial tool for assessing the abrasion resistance of textile products, particularly in industries where durability is paramount. According to a report by Textiles Intelligence, nearly 30% of returns in the textile market can be attributed to color fading and wear, highlighting the necessity for rigorous testing methods. By utilizing a crockmeter, manufacturers can simulate real-world wear conditions, ensuring that fabrics will withstand regular use and maintain their appearance.

Moreover, the precision offered by crockmeters allows for standardized testing according to established norms such as ISO 105-C06, which helps manufacturers achieve compliance with international quality standards. Studies have shown that textiles tested using a crockmeter exhibit a significant reduction in customer complaints related to color transfer and fading. This not only improves customer satisfaction but also reinforces brand reputation in a highly competitive market. As brands continue to prioritize quality assurance, the crockmeter becomes an invaluable asset in maintaining high industry standards.

Using a crockmeter rubbing fastness tester in quality control can significantly reduce customer complaints and elevate satisfaction rates. By precisely measuring the rubbing fastness of textiles, manufacturers can identify potential issues before products reach the market. This proactive approach allows for timely adjustments in production processes, ensuring that the end product not only meets but exceeds consumer expectations.

Furthermore, consistent testing with a crockmeter enables brands to develop a reliable reputation for quality. When customers receive items that maintain their color and integrity even after repeated use, their trust in the brand deepens. This translates to increased customer loyalty and a boost in repeat purchases, as satisfied customers are more likely to recommend the product to others. The effective use of a crockmeter, therefore, plays a crucial role in maintaining high standards of quality and enhancing overall customer experiences.